Renewable green environment-friendly material and preparation method and application thereof

A green environmental protection, material processing technology, applied in chemical instruments and methods, other chemical processes, adsorbed water/sewage treatment, etc., can solve the problems of high price, unsuitable for sewage treatment applications, etc., and achieve low price and good wastewater treatment capacity. , the effect of good adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The preparation method of renewable green environmental protection material, its specific steps are:

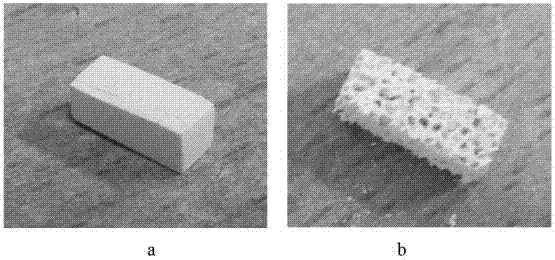

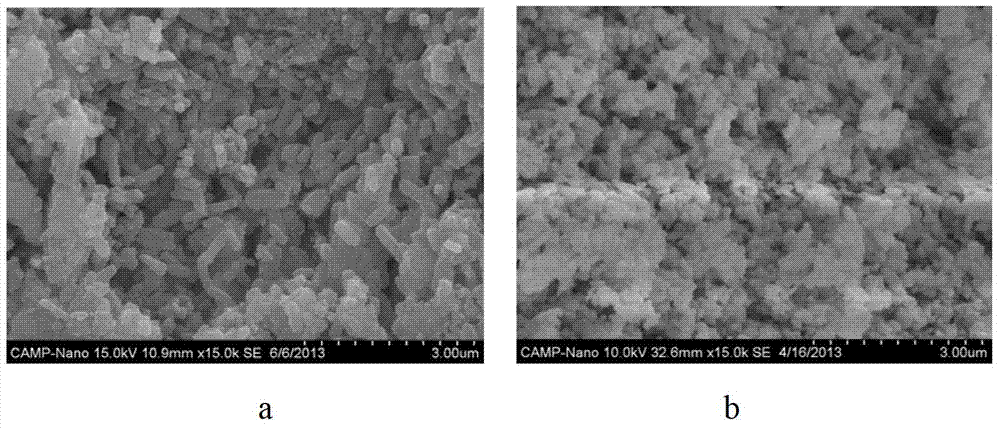

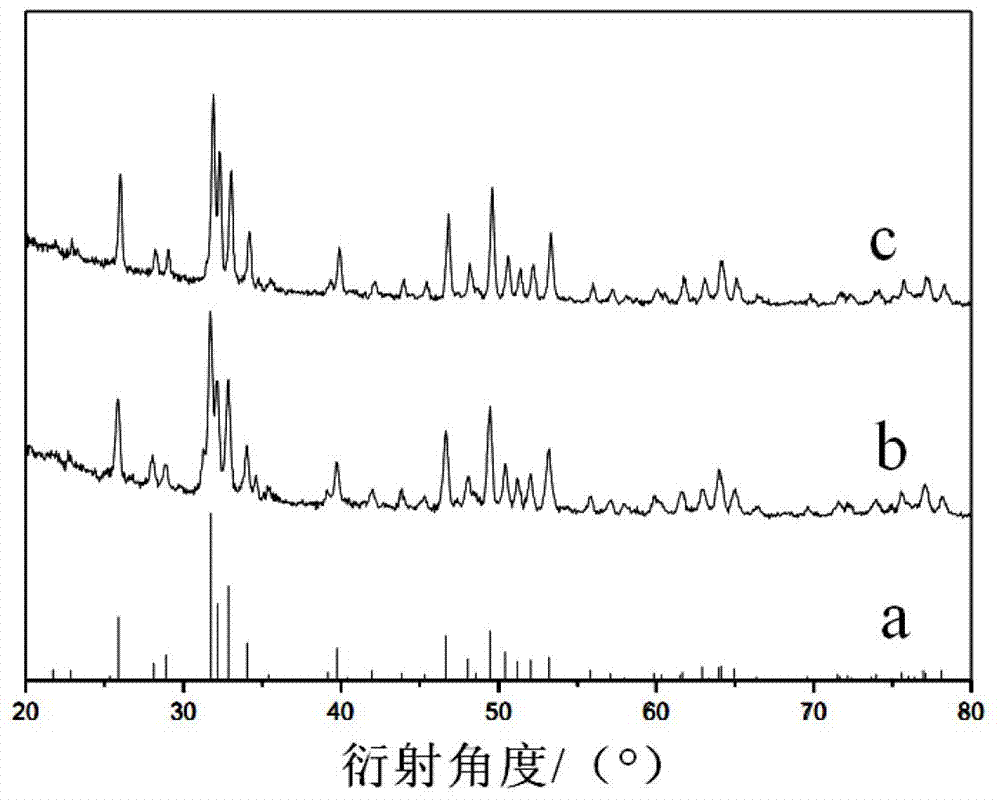

[0035] The bovine bone is calcined in a muffle furnace to remove organic components. The calcining temperature is 500°C and the calcining time is 6 hours. Then the fired product is taken out and cooled in the air to obtain a renewable green environmental protection material.

[0036] The porous bovine cancellous bone obtained through the above-mentioned calcination operation, its main component is hydroxyapatite Ca 10 (PO 4 ) 6 (OH) 2 , the porosity is 85%.

[0037] The method for treating wastewater by using renewable green environmental protection materials, the specific steps are:

[0038] Take 0.0722g of the massive porous bovine cancellous bone obtained through the above-mentioned calcination operation (renewable green environmental protection material), put it into 100ml of Pb 2+ Pb(NO 3 ) 2 solution (Pb(NO 3 ) 2 solution as wastewater), in which the ren...

Embodiment 2

[0040] The preparation method of renewable green environmental protection material, its specific steps are:

[0041] The bovine bone is calcined in a muffle furnace to remove organic components. The calcining temperature is 650°C and the calcining time is 3 hours. Then the fired product is taken out and cooled in the air to obtain a renewable green environmental protection material.

[0042] The porous bovine cancellous bone obtained through the above-mentioned calcination operation, its main component is hydroxyapatite Ca 10 (PO 4 ) 6 (OH) 2 , the porosity is 83.8%.

[0043] The method for treating wastewater by using renewable green environmental protection materials, the specific steps are:

[0044] Take 0.0753g of the massive porous bovine cancellous bone obtained through the above-mentioned calcination operation (renewable green environmental protection material), put it into 100ml of Pb 2+ Pb(NO 3 ) 2 solution (Pb(NO 3 ) 2 solution as wastewater), in which the r...

Embodiment 3

[0046] The preparation method of renewable green environmental protection material, its specific steps are:

[0047] The bovine bone is calcined in a muffle furnace to remove organic components. The calcining temperature is 600°C and the calcining time is 3 hours. Then the fired product is taken out and cooled in the air to obtain a renewable green environmental protection material.

[0048] The porous bovine cancellous bone obtained through the above-mentioned calcination operation, its main component is hydroxyapatite Ca 10 (PO 4 ) 6 (OH) 2 , the porosity is 81.3%.

[0049] The method for treating wastewater by using renewable green environmental protection materials, the specific steps are:

[0050] Take 0.0693g of the massive porous bovine cancellous bone obtained through the above-mentioned calcination operation (renewable green environmental protection material), put it into 100ml Zn 2+ Zn(NO 3 ) 2 solution (Zn(NO 3 ) 2 solution as wastewater), in which the rene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com