Bionic human bone based on 3D printing and manufacturing method thereof

A 3D printing and manufacturing method technology, applied in tissue regeneration, medical science, prosthesis, etc., can solve problems such as slow molding speed, brittle parts, and limited space for adjusting sintering shrinkage rate, and achieve the effect of avoiding cracks and bending

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

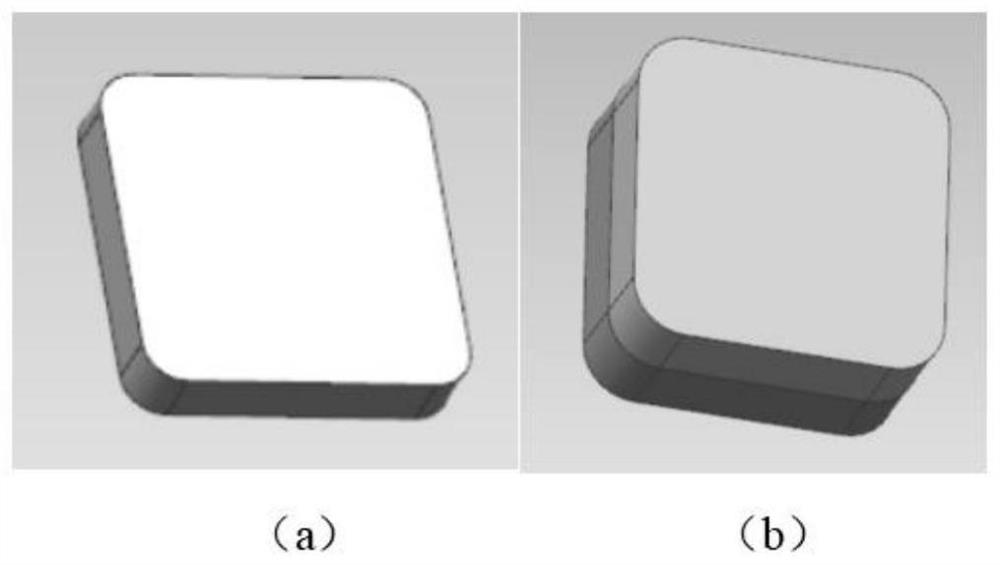

Image

Examples

Embodiment

[0039] see Figure 5 , the present embodiment provides a bionic human bone manufacturing method based on 3D printing:

[0040] The ceramic raw materials used include: A-type silicon nitride, B-type silicon nitride, sintering aids, and silane coupling agents.

[0041]a) setting the initial ratio of A-type silicon nitride and B-type silicon nitride in the ceramic raw material;

[0042] b) Use a planetary ball mill to mill each component in the ceramic raw material at 350r / min for 6h, and mix them uniformly;

[0043] c) drying at 60°C, and sieving to 100 mesh;

[0044] d) Design the first layer model of the bionic human bone;

[0045] e) adding resin, photoinitiator, and dispersant to the mixed ceramic raw materials to prepare 3D printing slurry, and then 3D printing;

[0046] f) degreasing;

[0047] g) sintering into porcelain at 1800°C to obtain the first layer of ceramic parts, and measuring the shrinkage of the first layer of ceramic parts;

[0048] h) Design the second...

Embodiment 2

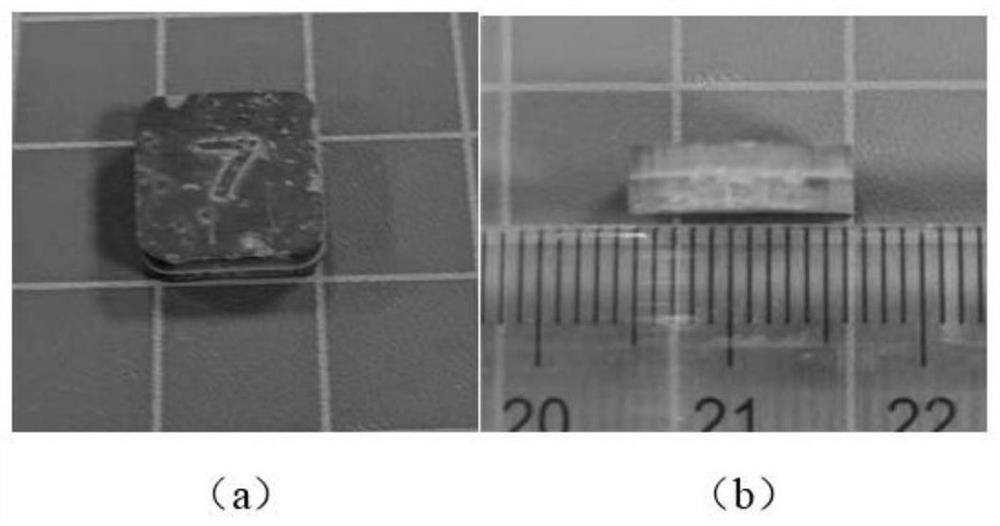

[0072] According to the performance results in Table 1 and Table 2, the ratio of A-type silicon nitride and B-type silicon nitride in the first layer of ceramic raw materials was adjusted according to the shrinkage rate of the second layer ceramic part No. 22. The proportion of A-type silicon nitride and B-type silicon nitride in the first layer of ceramic raw materials for preparing bionic human bones is 3.4:6.6, and the corresponding linear shrinkage rate of the obtained first layer of ceramic parts is 22.60%, and the porosity is 27.34%. , The flexural strength is 350.68MPa. The shrinkage ratio of the first layer of ceramic parts and the second layer of ceramic parts is matched, and the joint surface will not bend and crack.

[0073] Bionic human bone embodiment 3

[0074] According to the performance results in Table 1 and Table 2, the ratio of A-type silicon nitride and B-type silicon nitride in the first layer of ceramic raw materials was adjusted according to the shrink...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Median particle size | aaaaa | aaaaa |

| Median particle size | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com