Makeup remover mousse and preparation method thereof

A technology for removing makeup mousse and snail extract, which is applied to cosmetic preparations, cosmetic preparations, cosmetics and other directions, can solve problems such as difficulty in use, dry skin, lack of moisture, etc., and is convenient for large-scale industrial production and prevents dry skin. , the preparation method is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

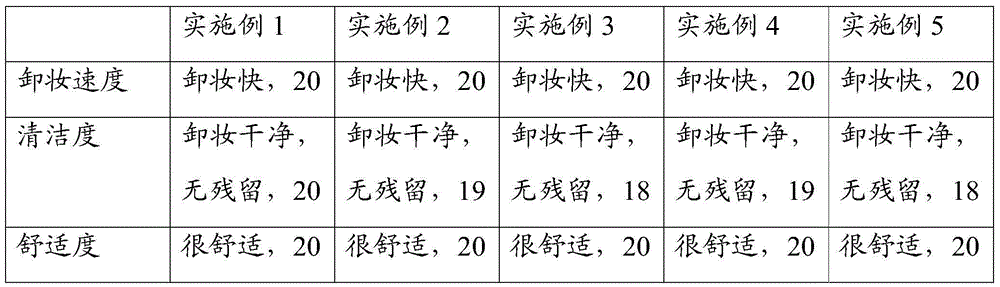

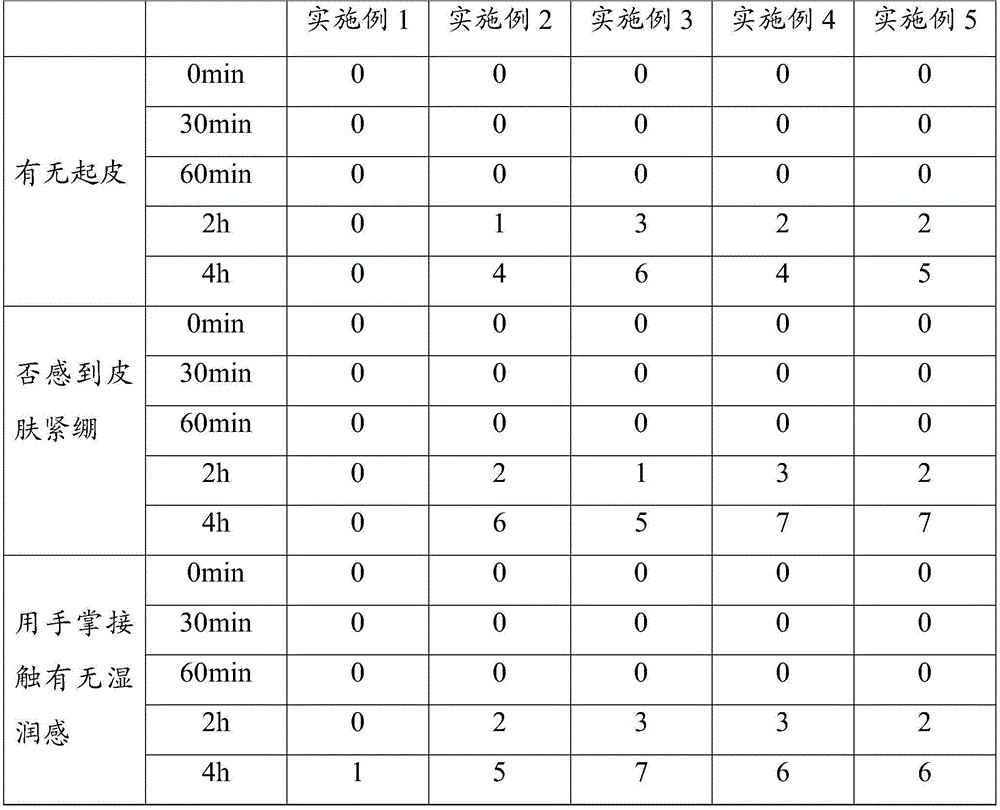

Examples

Embodiment 1

[0032] The cleansing mousse is made of the following components in parts by weight: 75 parts of water, 4 parts of betaine, 6 parts of potassium cocoyl glycinate, 3 parts of cocamidopropyl betaine, cetyl glucoside 2 parts, 3 parts of potassium cocoate, 2.5 parts of PEG-7 glyceryl cocoate, 4 parts of PEG-6 caprylic / capric glycerides, 5 parts of dipropylene glycol, 1.5 parts of BASAM, 0.3 parts of snail extract 0.1 part of disodium EDTA, 0.3 part of phenoxyethanol, 0.003 part of N950 preservative, and 0.005 part of essence.

[0033] The preparation method of this cleansing mousse comprises the following steps successively:

[0034] a. Take formula amount of water, PEG-6 caprylic / capric glycerides, potassium cocoyl glycinate, cocamidopropyl betaine, potassium cocoate, PEG-7 glyceryl cocoate, betaine and Add dipropylene glycol into the emulsification pot, disperse homogeneously, and then keep the temperature at 80°C for 5 minutes;

[0035] b. Add cetyl glucoside to the emulsifica...

Embodiment 2

[0038] A cleansing mousse, which is made of the following components by weight: 92.6 parts of water, 1.5 parts of betaine, 10 parts of potassium cocoyl glycinate, 1 part of cocamidopropyl betaine, cetyl 3.5 parts of glucoside, 1 part of potassium cocoate, 4 parts of PEG-7 glyceryl cocoate, 0.5 parts of PEG-6 caprylic / capric glycerides, 7 parts of dipropylene glycol, 0.2 parts of BASAM, snail extract 0.2 parts of liquid, 0.3 parts of disodium EDTA, 0.1 parts of phenoxyethanol, 0.006 parts of N950 preservative, and 0.001 parts of essence.

[0039] The preparation method of this cleansing mousse comprises the following steps successively:

[0040] a. Take formula amount of water, PEG-6 caprylic / capric glycerides, potassium cocoyl glycinate, cocamidopropyl betaine, potassium cocoate, PEG-7 glyceryl cocoate, betaine and Add dipropylene glycol into the emulsification pot, disperse homogeneously, and then keep the temperature at 75°C for 8 minutes;

[0041] b. Add cetyl glucoside t...

Embodiment 3

[0044]A cleansing mousse, which is made of the following components by weight: 41.7 parts of water, 6 parts of betaine, 2 parts of potassium cocoyl glycinate, 5 parts of cocamidopropyl betaine, cetyl 0.5 parts of glucoside, 6 parts of potassium cocoate, 0.5 parts of PEG-7 glyceryl cocoate, 5 parts of PEG-6 caprylic / capric glycerides, 1 part of dipropylene glycol, 2.8 parts of BASAM, snail extract 0.5 parts of liquid, 0.05 parts of disodium EDTA, 0.6 parts of phenoxyethanol, 0.002 parts of N950 preservative, and 0.01 parts of essence.

[0045] The preparation method of this cleansing mousse comprises the following steps successively:

[0046] a. Take formula amount of water, PEG-6 caprylic / capric glycerides, potassium cocoyl glycinate, cocamidopropyl betaine, potassium cocoate, PEG-7 glyceryl cocoate, betaine and Add dipropylene glycol into the emulsification pot, disperse homogeneously, and then keep the temperature at 85°C for 3 minutes;

[0047] b. Add cetyl glucoside into...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com