A system and method for recycling unqualified sodium hypochlorite

A qualified technology for sodium hypochlorite, applied in the field of unqualified sodium hypochlorite recycling system, can solve the problems of increasing the load of sewage treatment station, excessive acetylene sulfur, phosphorus content, waste of resources, etc., to reduce the company's economic loss, reduce raw material costs, solve perishable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

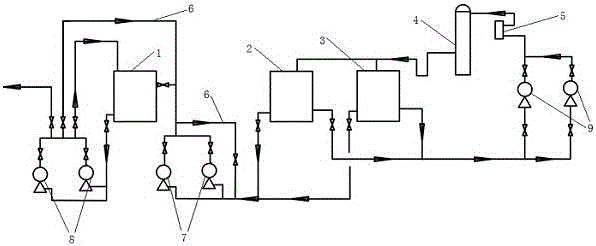

[0025] An unqualified sodium hypochlorite recycling system, comprising a secondary lye absorption tower 4, a secondary lye circulation tank 2, a sodium hypochlorite finished product tank 1, a secondary lye circulation tank (standby) 3, a cooler 5, and a transmission pipe; It is characterized in that the secondary lye absorption tower 4 is connected to the secondary lye circulation tank 2 and the secondary lye circulation tank (standby) 3 through branch pipes, and the secondary lye circulation tank 2 and the secondary lye circulation tank (standby) ) The outlet end of 3 is connected with the secondary lye circulation pump 9, and the secondary lye circulation pump 9 is connected with the condenser 5 and the secondary lye absorption tower 4 successively, and the outlet end of the secondary lye circulation tank 2 is also connected with the sodium hypochlorite The inlet end of finished product tank 1 links to each other, and the outlet end of sodium hypochlorite finished product tan...

Embodiment 2

[0032] A kind of unqualified sodium hypochlorite recycling system, the structure is the same as embodiment 1, the difference is that a sodium hypochlorite finished product pump A / B is arranged between the outlet end of the secondary lye circulation tank 2 and the inlet end of the sodium hypochlorite finished product tank 1 (7).

Embodiment 3

[0034] An unqualified sodium hypochlorite recycling system, the structure is the same as that of Example 1, the difference is that a sodium hypochlorite product pump C / D (8) is provided between the outlet end of the sodium hypochlorite product tank 1 and the transmission pipe.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com