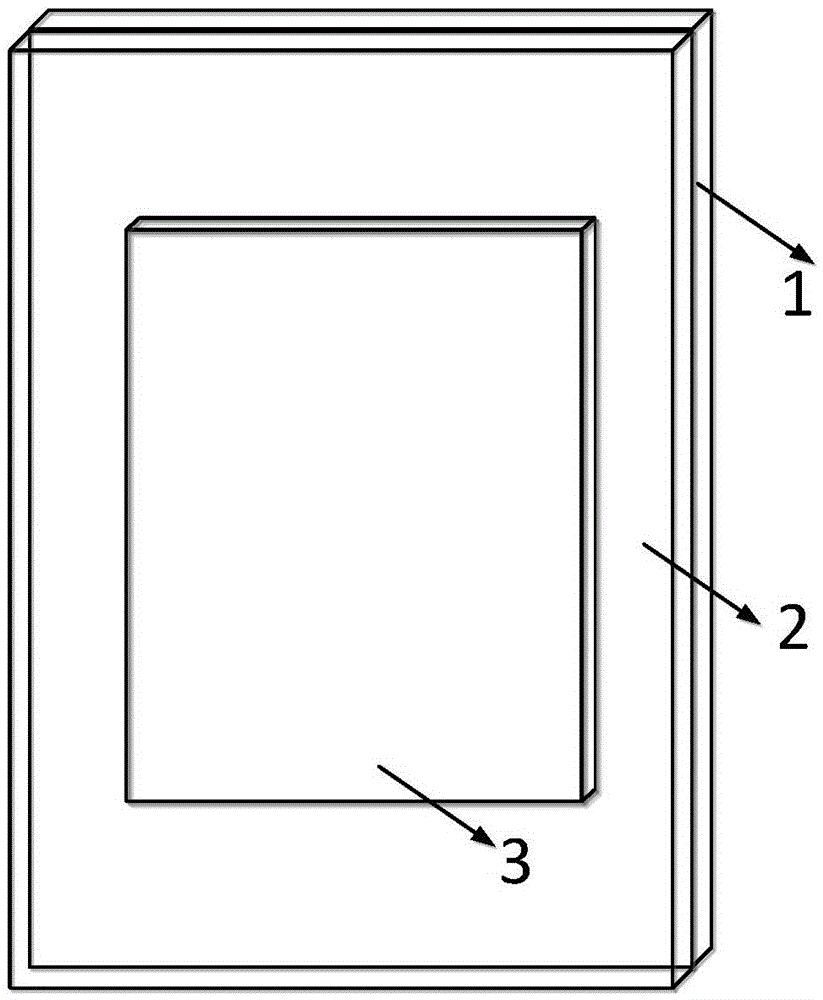

A Dielectrophoretic Particle Sorting Microfluidic Chip

A technology of microfluidic chip and dielectrophoresis, which is applied in the direction of laboratory equipment, laboratory containers, chemical instruments and methods, etc., can solve the problems of limited range of electrical signal amplitude and difficulty in flexible adjustment, and achieve low cost , proper layout and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

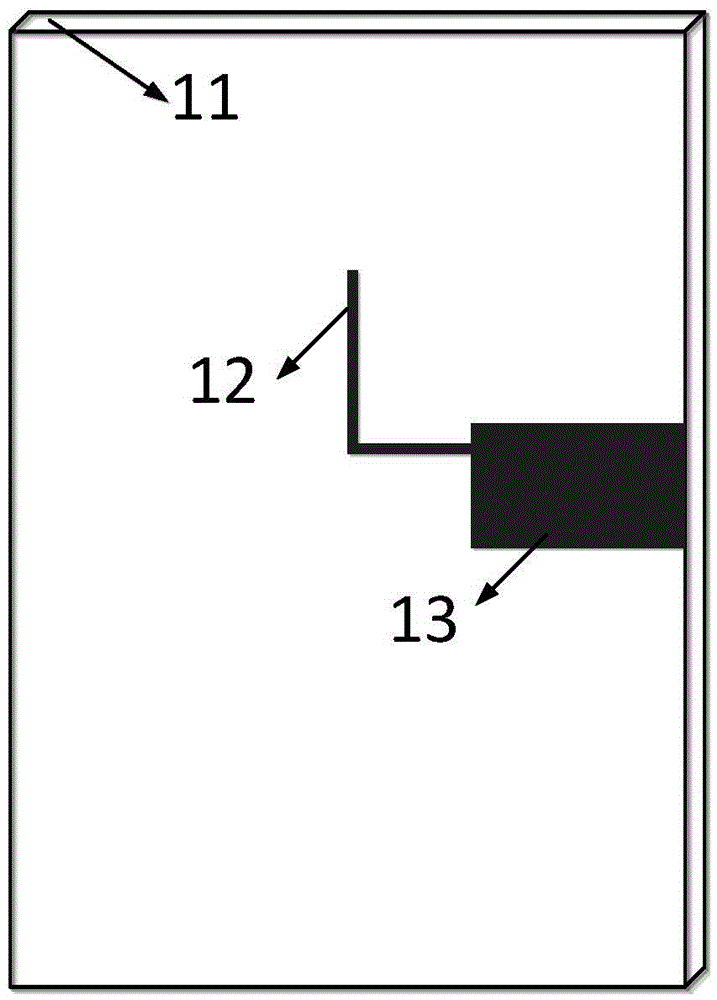

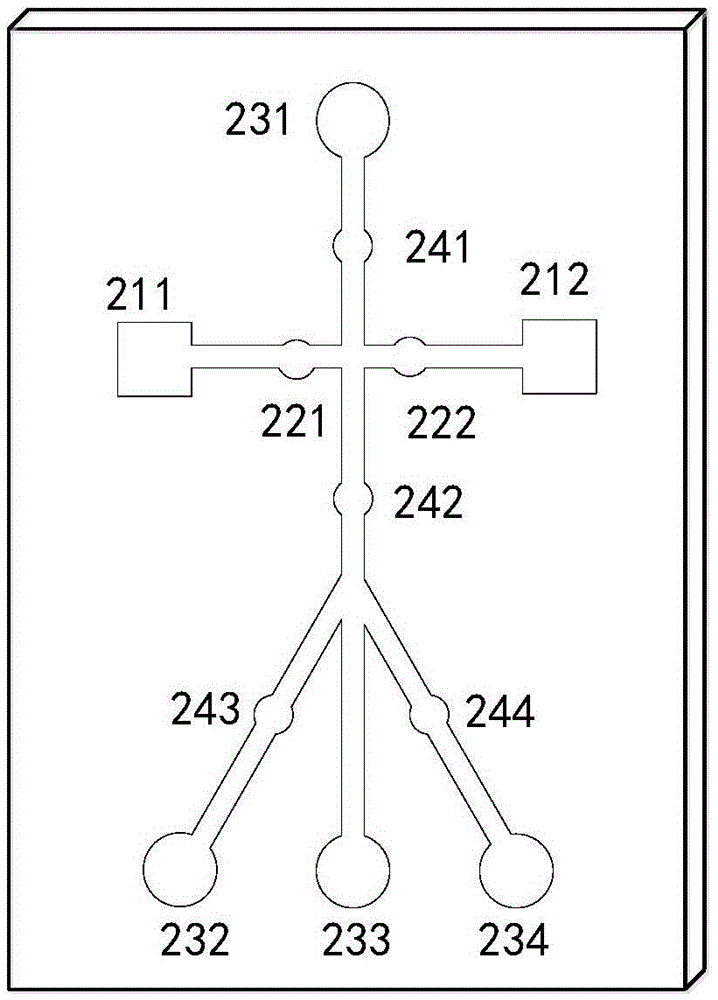

[0027] The first plating solution solenoid valve 321 and the second plating solution solenoid valve 322 are closed, all sorting solution solenoid valves are opened, and the solution containing dead and alive yeast cells is passed into the sorting solution inlet 231, and the dead and alive yeast cells are respectively subjected to Dielectrophoretic forces of different properties (positive or negative). Here, the width of the microchannel is 200um, the depth is 50um, the diameters of all the solenoid valve stations for the plating solution and the solenoid valve stations for the sorting solution are 3mm, and the vertical distance between the plating electrode and the plane electrode is 15um. Dead cells flow out from the first sorting solution outlet 232 and the third sorting solution outlet 234, corresponding to the weak electric field region; live cells flow out from the second sorting solution outlet 233, corresponding to the strong electric field region.

Embodiment 2

[0029] The first plating solution solenoid valve 321 and the second plating solution solenoid valve 322 are closed, all sorting solution solenoid valves are opened, and the human blood containing 1:50 dilution is passed into the sorting solution inlet 231, and red blood cells and white blood cells are respectively subjected to Dielectrophoretic forces of different properties (positive or negative). Here, the width of the microchannel is 120um, the depth is 60um, the diameters of all the solenoid valve stations for the plating solution and the solenoid valve stations for the sorting solution are 8mm, and the vertical distance between the plating electrode and the plane electrode is 20um. The red blood cells flow out from the first sorting solution outlet 232 and the third sorting solution outlet 234, corresponding to the weak electric field area; the white blood cells flow out from the second sorting solution sampling port 233, corresponding to the strong electric field area.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com