Material grinding bin suitable for roll cutting grinding mill

A grinder and material technology, applied in the direction of grain processing, etc., can solve the problems of inability to realize automatic feeding and discharging, waste of human resources, low production efficiency, etc., to prolong service life, improve work efficiency, and reduce failures Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings, but the content protected by the present invention is not limited to the following description.

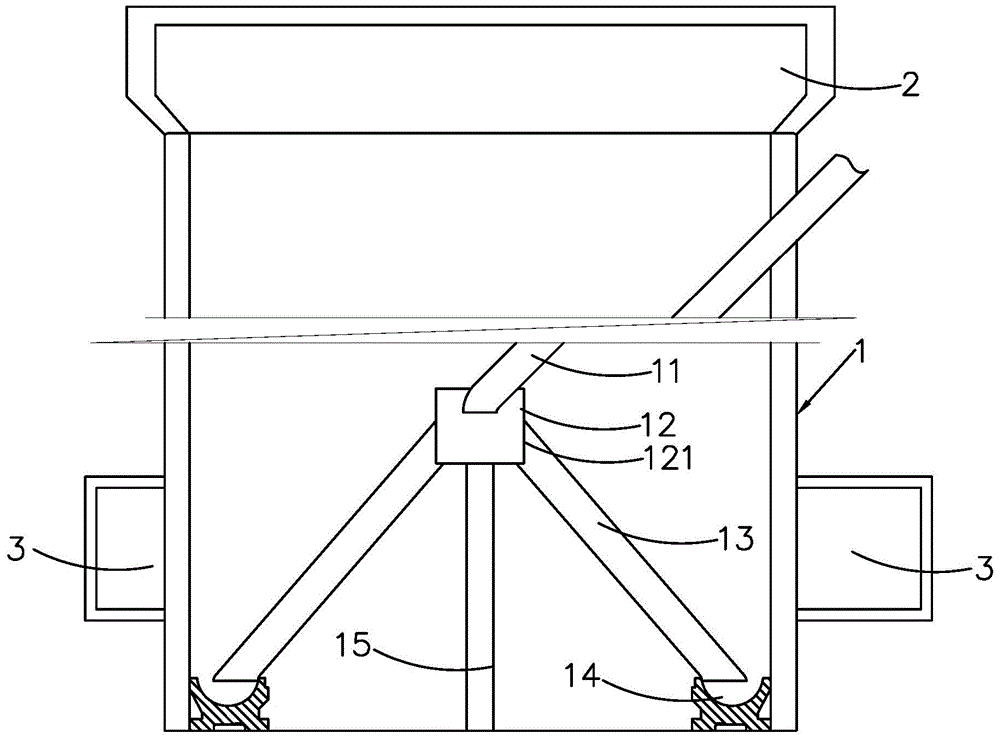

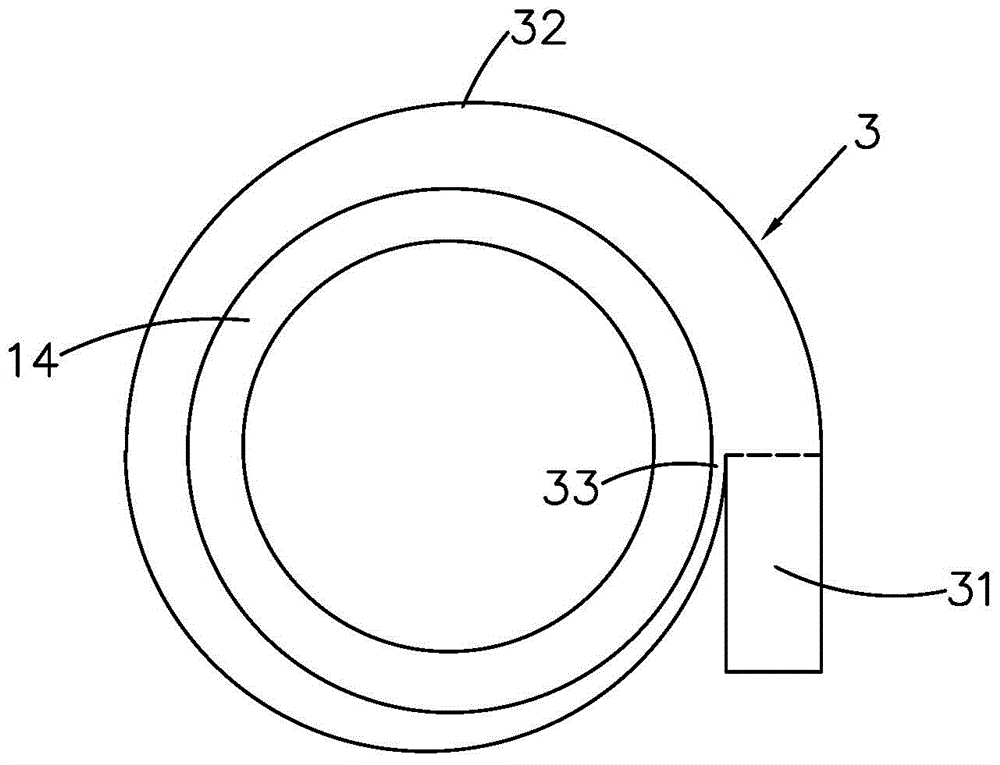

[0018] like figure 1 As shown, a material grinding bin suitable for a roller cutting grinder includes a bin body 1, a decompression chamber 2 located above the bin body 1, and an air duct 3 surrounding the outside of the grinding bin body 1. The air duct 3 and the One side of the junction of the warehouse body 1 is provided with a plurality of air inlet holes; the warehouse body 1 includes a feed pipe 11, a feed bin 12, a discharge pipe 13 and a U-shaped ring groove 14 arranged inside it, The feed port of feed pipe 11 stretches out the side of bin body 1, and the discharge port of feed pipe 11 is connected with the feed port of feed bin 12, and feed bin 12 is fixedly installed on the rotating shaft 15, and on the side of feed bin 2 At least one sil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com