Low-frequency ultrasonic triple atomization nozzle

An atomizing nozzle and ultrasonic technology, applied in the direction of spraying devices, liquid spraying devices, etc., can solve the problems of underutilized sound field energy, large atomized cultivation, high reliability, etc., to achieve full absorption, low cost, Simple structure and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

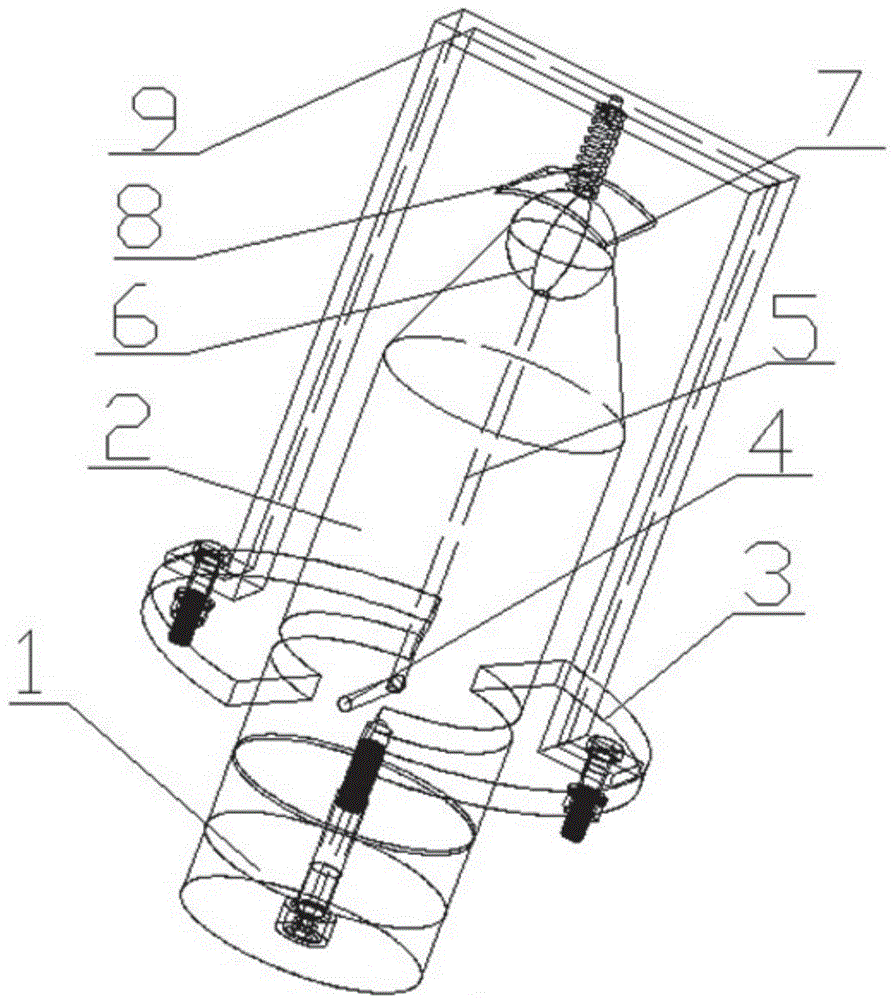

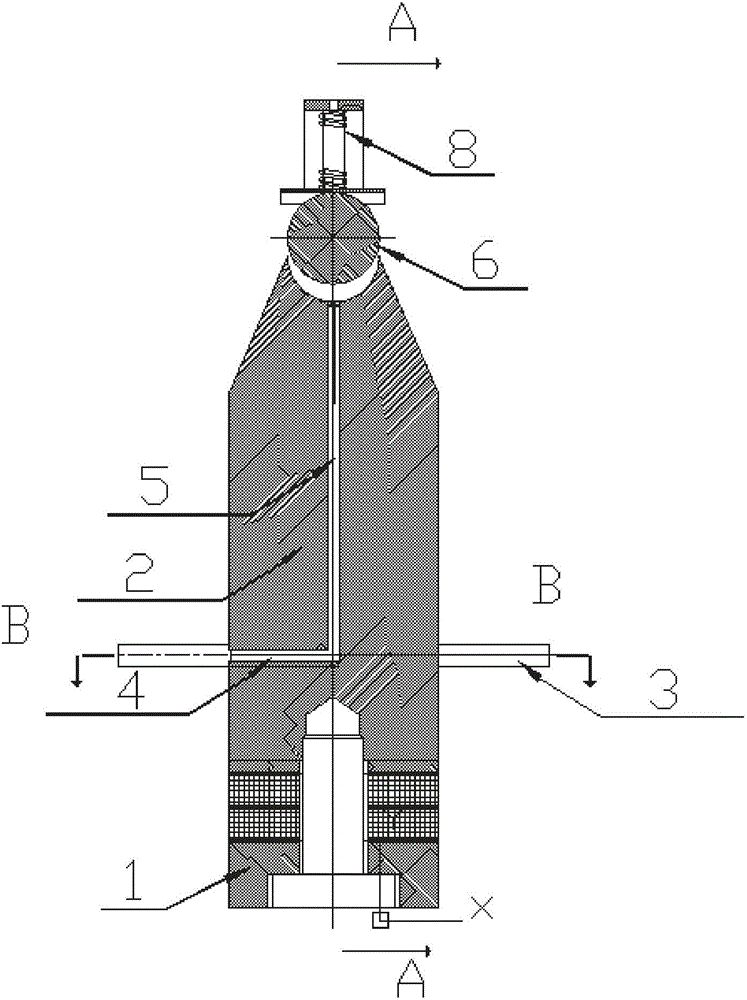

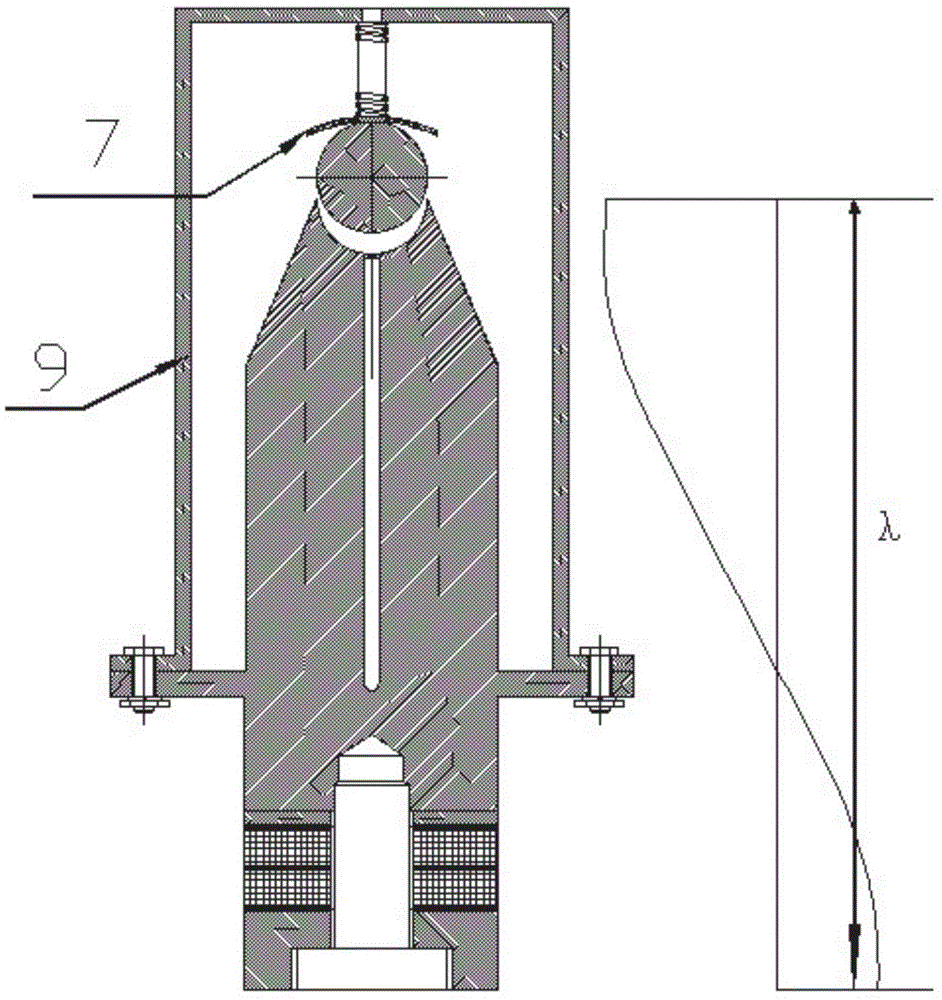

[0028] like Figure 1-5 As shown, a low-frequency ultrasonic three-time atomizing nozzle includes an ultrasonic transducer 1, a horn 2, an eccentric ball 6, a pressure block 7, a limit spring 8, a support frame 9, a liquid inlet hole 4, and a liquid outlet hole 5 The upper end surface of the ultrasonic transducer 1 is bonded to the lower end surface of the horn 2, and the upper conical surface of the horn 2 is provided with a nozzle groove, and an eccentric ball 6 is arranged in the nozzle groove; The wave node of the transducer 1 is provided with a flange 3 (such as image 3 As shown, λ represents the wavelength, and the curve on the right side of the figure is to illustrate that the position of the flange is at the wave node, because the vibration amplitude at the wave node is the smallest, and the arrangement of the flange is the most suitab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com