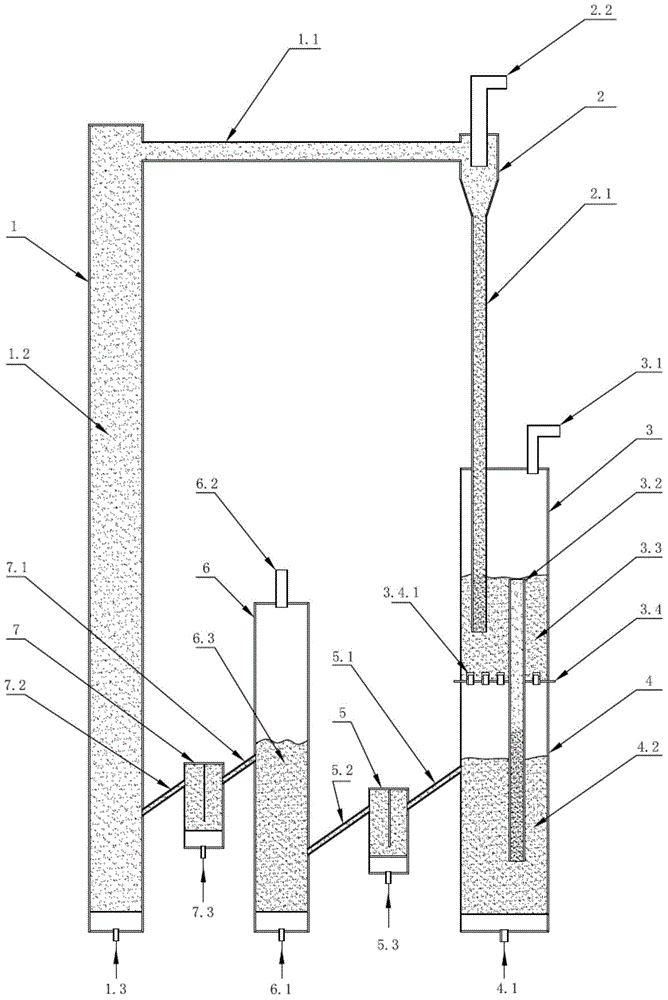

Chemical chain hydrogen production device and method based on iron-based oxygen carrier graded reduction

A hydrogen production device and oxygen carrier technology, applied in the production of hydrogen, etc., can solve the problems of oxygen carrier particles not flowing normally, affecting product purity, and low gas fuel conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0032] A method of a chemical chain hydrogen production device based on the graded reduction of iron-based oxygen carriers is that the gas fuel does not directly contact with water vapor, and performs a water-gas shift reaction to produce hydrogen, but uses a metal oxide carrier in the air reactor 1, The alternate oxidation-reduction reaction between the fuel reactor 4 and the steam reactor 6 realizes the transfer of oxygen and completes the conversion of the chemical energy of the gaseous fuel. The reduced oxygen carrier reacts with high-temperature steam to generate H 2 . Among them, the oxygen carrier includes Fe 2 O 3 Iron-based oxygen carrier particles 1.2, Fe 3 O 4 state iron-based oxygen carrier particles 3.3, FeO state iron-based oxygen carrier particles 4.2 and Fe 3 O 4 State iron-based oxygen carrier particles 6.3; the specific method includes the following steps:

[0033] 1) Oxygen carrier reduction reaction: In reduction reactor 3, Fe from air reactor 1 2 O ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com