Four-motor ultra-micro segregator

An ultra-fine separator and four-motor technology, which can be used in permeation/dialysis water/sewage treatment, etc., can solve the problem of motor energy consumption reduction, and achieve the effect of strong sinusoidal shear force, low energy consumption, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention provides a four-motor type ultra-fine separator. In order to make the purpose, technical scheme and effect of the present invention clearer and clearer, the present invention will be further described in detail with reference to the accompanying drawings and examples. It should be understood that the specific implementations described herein are only used to explain the present invention, but not to limit the present invention.

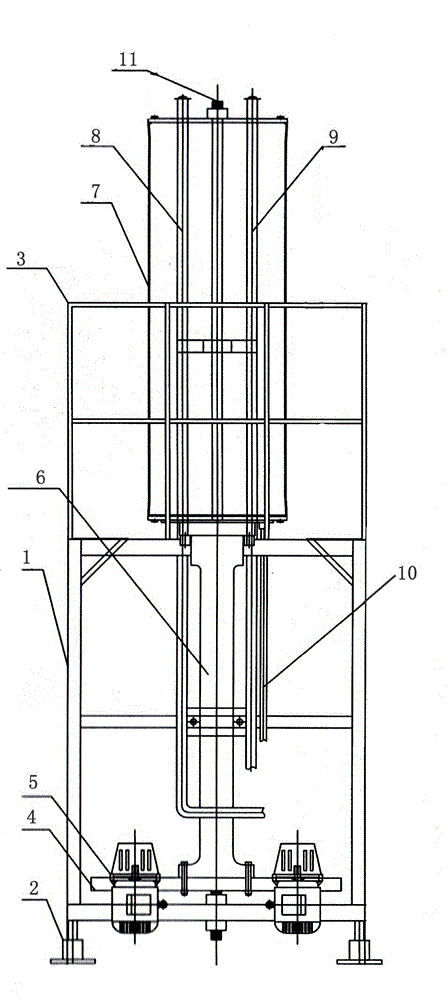

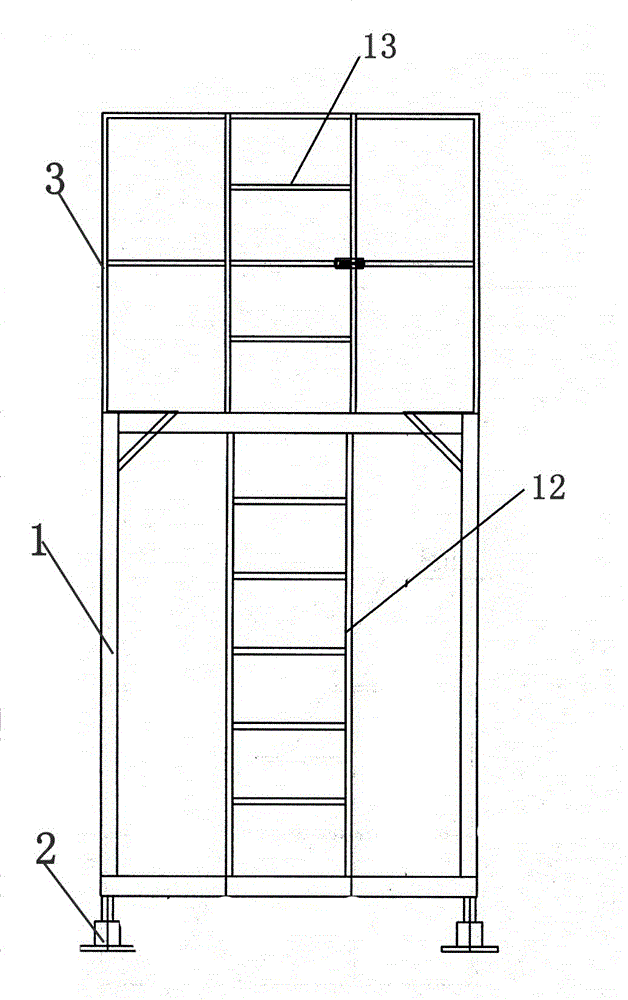

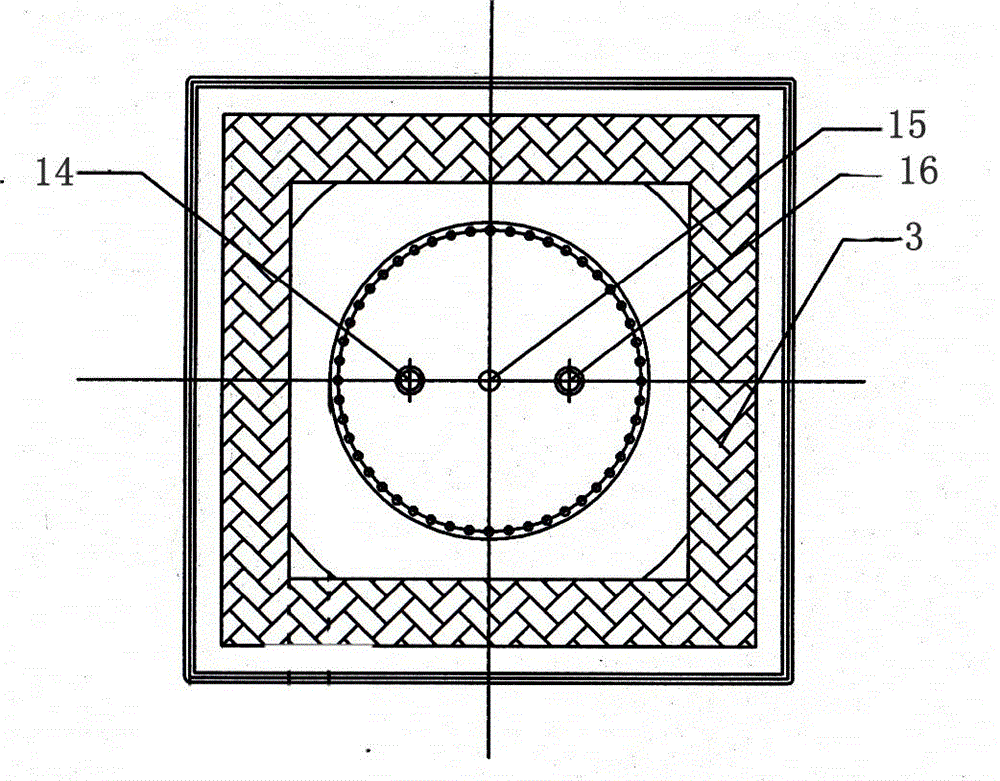

[0025] like figure 1 As shown, a four-motor type ultra-fine separator according to the present invention includes a main frame 1, an operation platform 3 connected above the main frame, a vibration bottom plate 4, a vibration motor 5, a vibration main component 6 and a membrane assembly 7; The four bottom corners of the main frame 1 are provided with shock-absorbing foot pads 2; a vibration base plate 4 is fixed at the center of the bottom of the main frame 1; Table vibrating motor 5; wherein, the vibration main component...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com