Layout method for preventing oxidation of dust collector in ladle refining treatment process

A ladle furnace refining and dedusting device technology, applied in the field of medium and thick plate steelmaking, to achieve temperature balance, reduce secondary oxidation, and improve cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

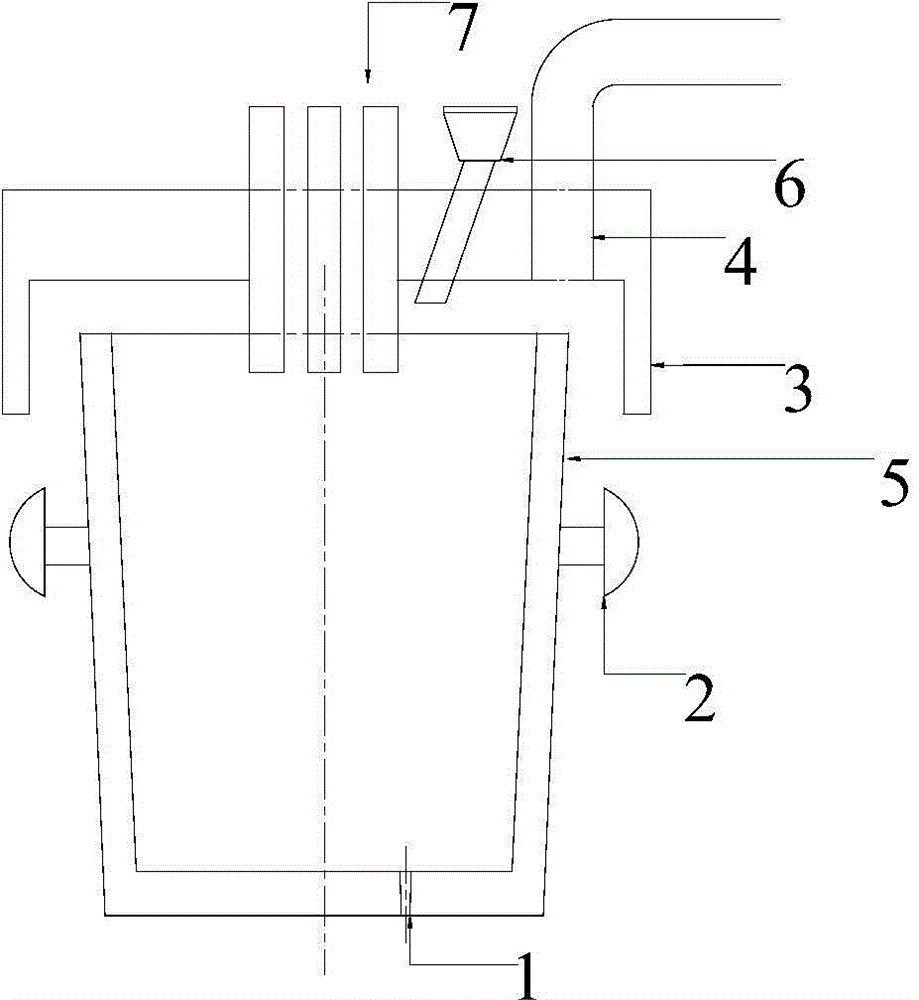

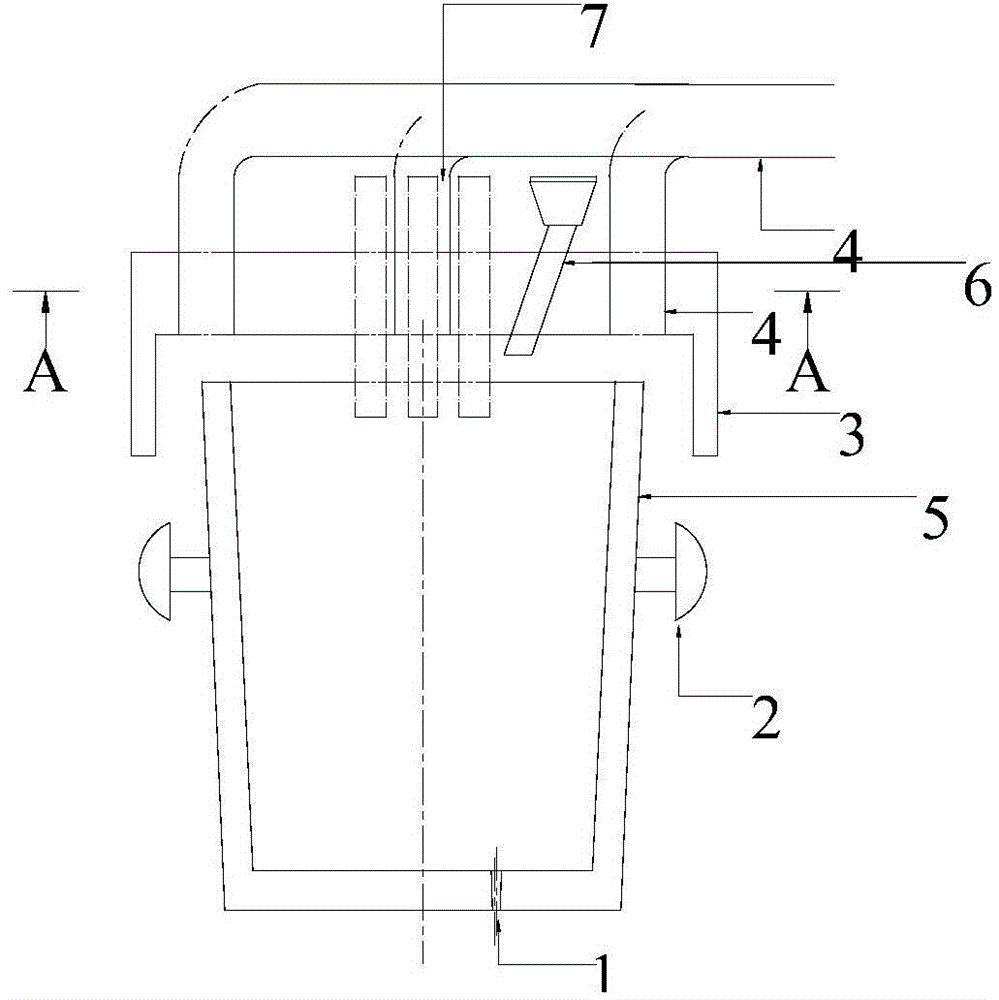

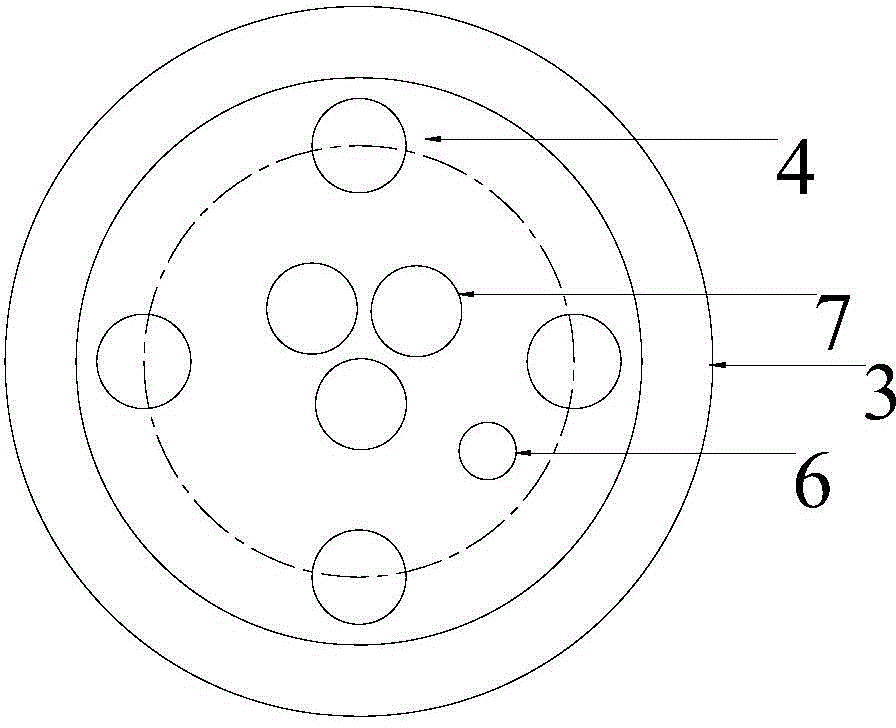

[0016] A method for arranging a dust removal device for preventing oxidation during the refining process of a ladle furnace;

[0017] Rearrange the suction port of the dust removal device. The new layout includes 4 suction ports, the molten steel capacity of the ladle furnace is 100t, and the diameter of the suction port main pipe is D=(4V / 3600*3.142*v)^0.5 , where; the flue gas flow V is 30m 3 / h; the flue gas velocity v is 14m / s, then the pipe diameter D is 1.21m, and the sum of the cross-sectional area of the newly arranged suction ports is the same as the cross-sectional area of the main pipe, so the diameter of each newly arranged suction port is 0.605m. When the dust removal system is turned on, the dust and protective gas (Ar gas) will be sucked into the dust removal system, and the air on both sides of the ladle furnace will also be sucked into the dust removal system evenly. Due to the installation of 4 suction ports, the dust removal power is reduced by 21%. , t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com