Industrial energy-saving anti-seismic building wall

A technology of energy-saving boards and core boards, which is applied in the direction of buildings, building components, and building structures. It can solve the problems of destroying the privacy requirements of rooms, harming people in earthquake collapses, and easy cracking of board seams, etc., to achieve strong structures and strong earthquake destructive power. Small, the effect of reducing exhaust emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

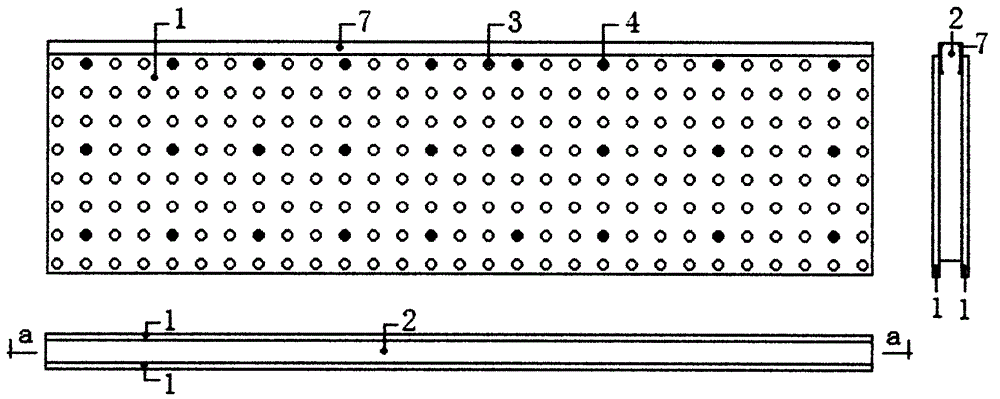

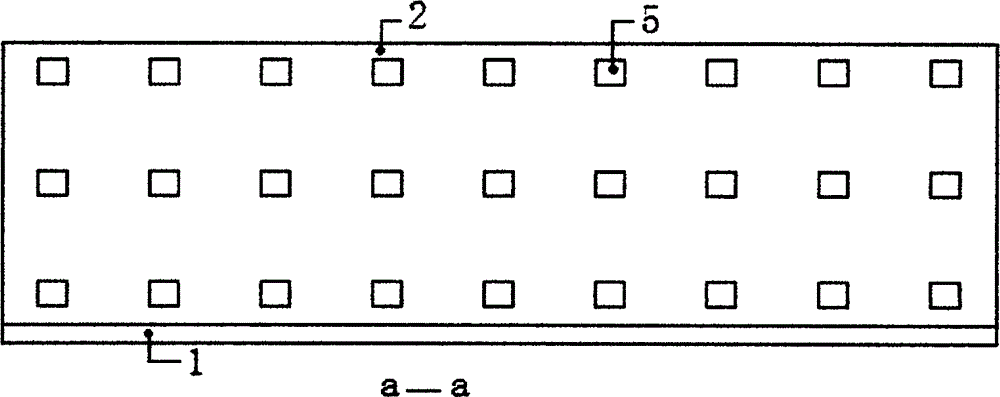

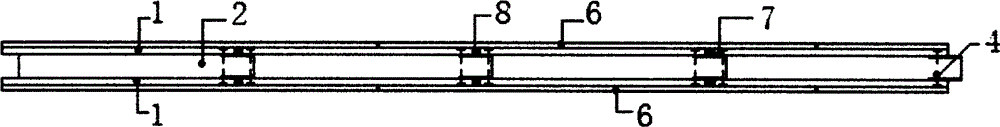

Method used

Image

Examples

Embodiment 1

[0024] Embodiment one: when the school building of the reinforced concrete frame structure of 10,000 square meters is carried out anti-seismic reinforcement, the original 240 thick brick walls in the building are removed, and the wallboard of the present invention is used instead, and the original wall red brick wall comprises cement mortar masonry and The weight per square meter of plastering is 532kg, and the weight of the wall per beam per extension meter is 1383kg. The wall-to-ground ratio is calculated as 1:2, and the weight of the wall per square meter of building is 1064kg. After adopting the wall body of the present invention, the weight per square meter of the wall body is 25kg on average, and the beam bearing wall weight per extended meter is 65kg, and the unit square meter building bearing wall weight is 50kg. The total weight reduction of the school building is 10,000 tons, which can reduce the earthquake destructive force by more than 50%, so that the original scho...

Embodiment 2

[0025] Embodiment two: the original design reinforced concrete floor (roof) surface, the steel structure super high-rise building of aerated brick masonry wall, after adopting the present invention, wall surface weight reduces 80%, surface building (house) weight reduces 50%, The weight of the shaped steel beam is reduced by 30%, the weight of the column is reduced by 10%, the overall weight of the building is reduced by 50%, and the structural steel of the original design of 1 million tons of steel is reduced by 30%. The economic, social and environmental benefits are very significant.

Embodiment 3

[0026] Embodiment three: After the construction of new socialist countryside adopts the present invention, the original reinforced concrete frame structure is replaced with a light steel frame structure, so that the original 6-magnitude earthquake will be earthquake-resistant and disaster-relief residential houses, and the 9-magnitude earthquake does not need earthquake-resistant disaster relief. This not only It can reduce earthquake damage, and it is also the foundation for solidifying national security and healthy development. When this kind of building is developed and expanded in the future, the value of demolition and reuse is very high, and it is the technology that can best reflect sustainable development.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com