Double-diamond-shaped connecting structure

A connection structure, double rhombus technology, applied in the direction of building structure, columns, pier columns, etc., can solve the problems of difficult production, welding and quality assurance, and achieve the effect of easy production, welding and quality assurance, and scientific structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below in conjunction with accompanying drawing and specific embodiment the present invention will be described in further detail:

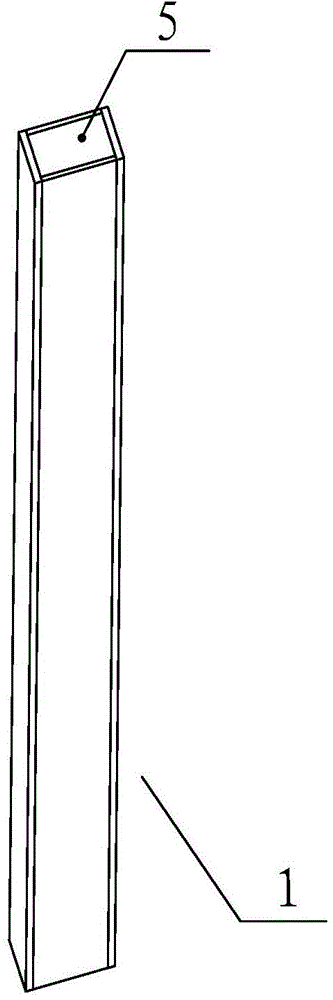

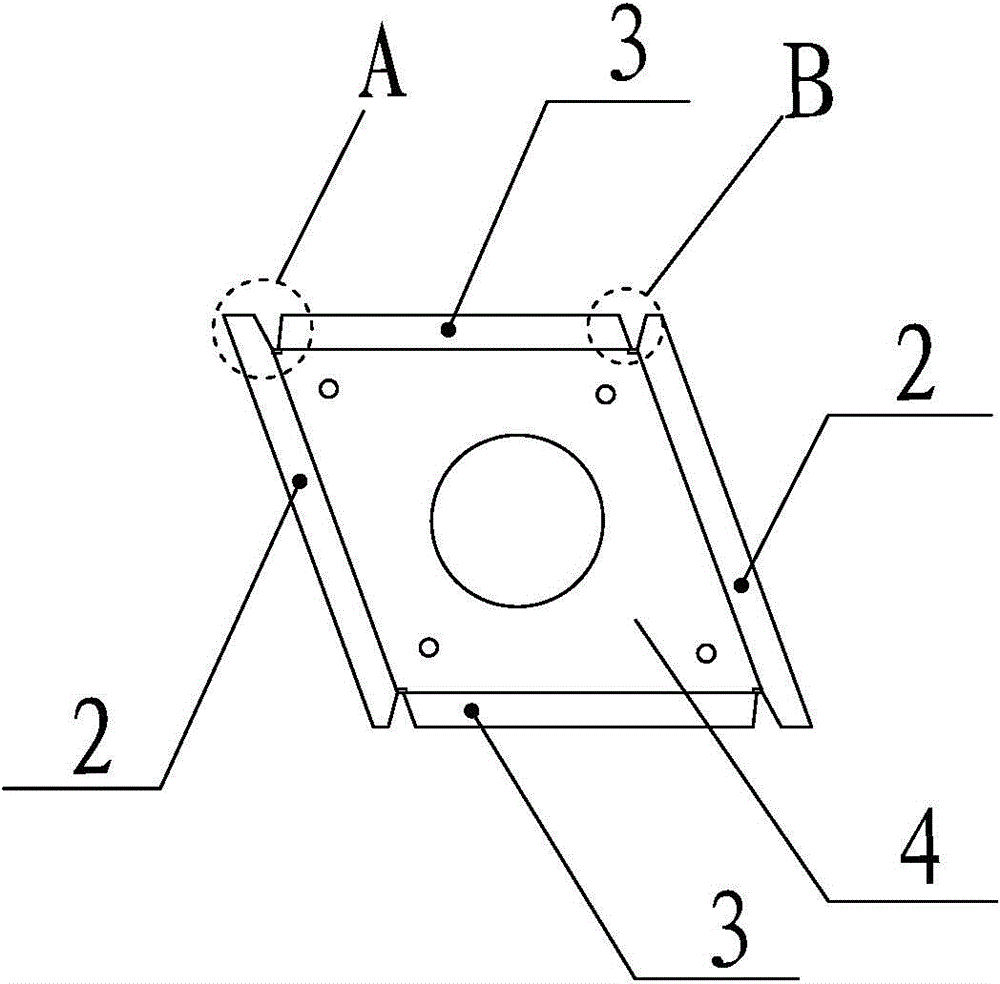

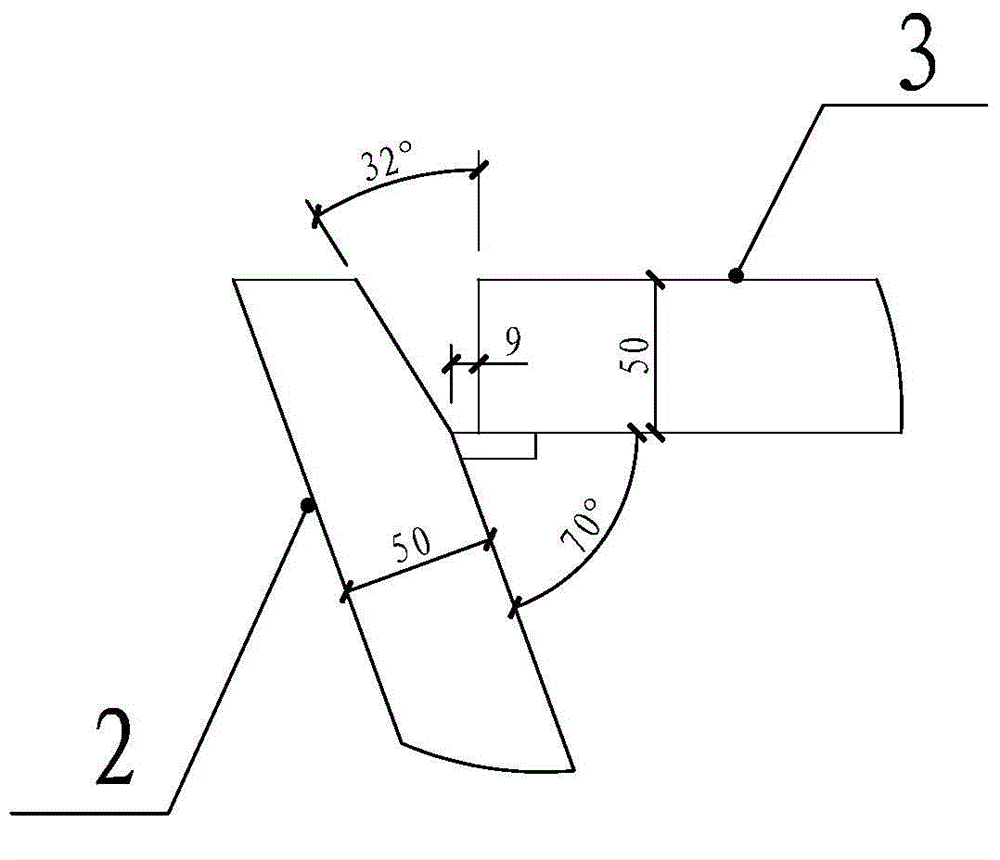

[0032] like Figure 4 The shown double rhombus connection structure 6 is formed by connecting two single rhombus boxes 1 through two double rhombus inter-column connecting plates 7 with the same dimensions, as shown in figure 1 , figure 2 As shown, the single diamond-shaped box 1 is composed of two flange plates 2 and two webs 3 to form the side of the single diamond-shaped box 1, and the inner side of the single diamond-shaped box 1 is installed near the middle position to connect with the side T. The rhombus inner partition 4, the rhombus inner partition 4 is provided with a grouting hole and a vent hole, the diameter of the grouting hole is 200mm, the diameter of the vent hole is 25mm, the inner side of the single rhombus box 1 is installed with the The diamond-shaped sealing plate 5 with T-shaped side contact;

[0033] like Figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com