Solar water heater tank liner seal head and mounting method

A technology for solar water heaters and tanks, applied in solar thermal devices, solar thermal power generation, heating devices, etc., can solve the problems of high cost of flange heads, increased processing time, complex processing technology, etc., to facilitate subsequent processing and installation , Reduce the installation space, and the effect of simple processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

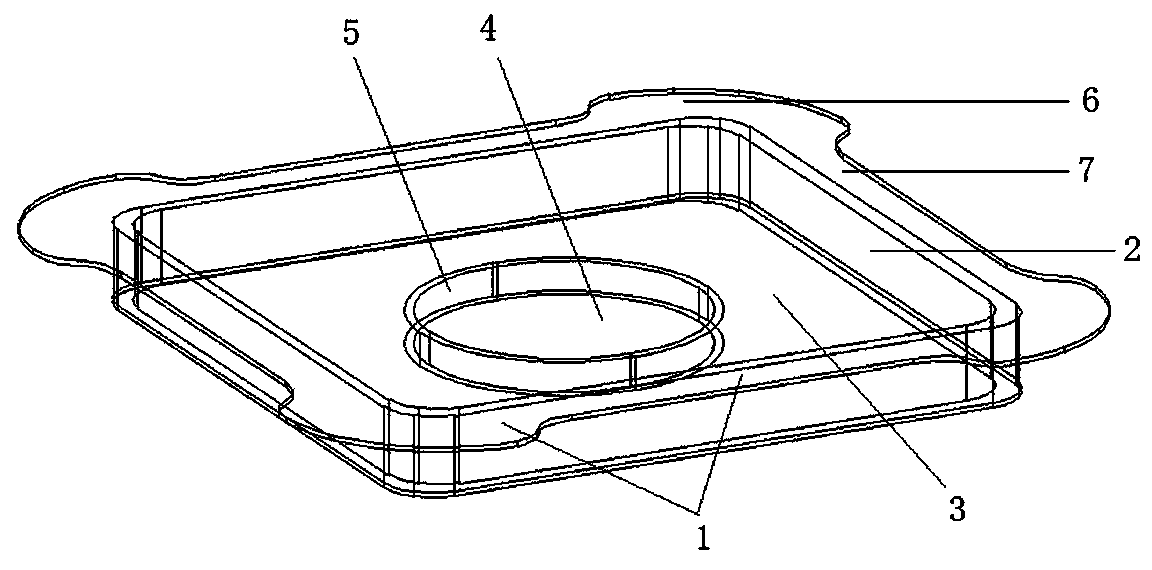

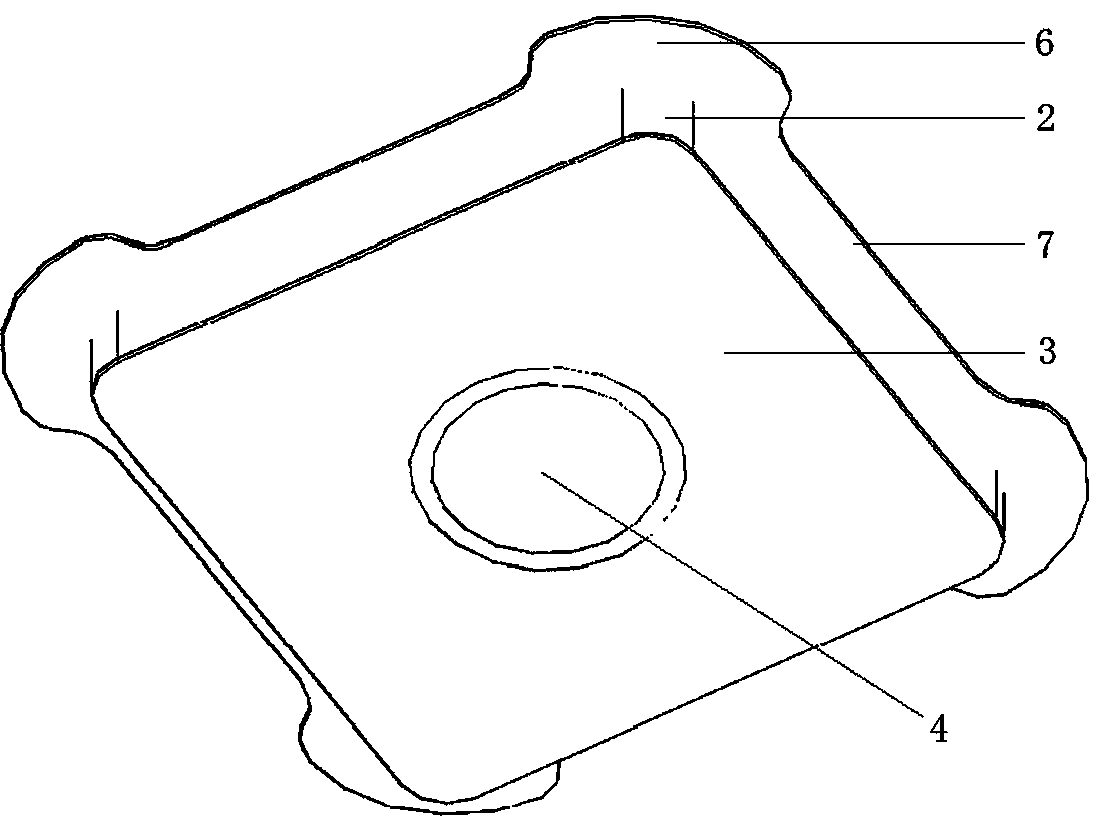

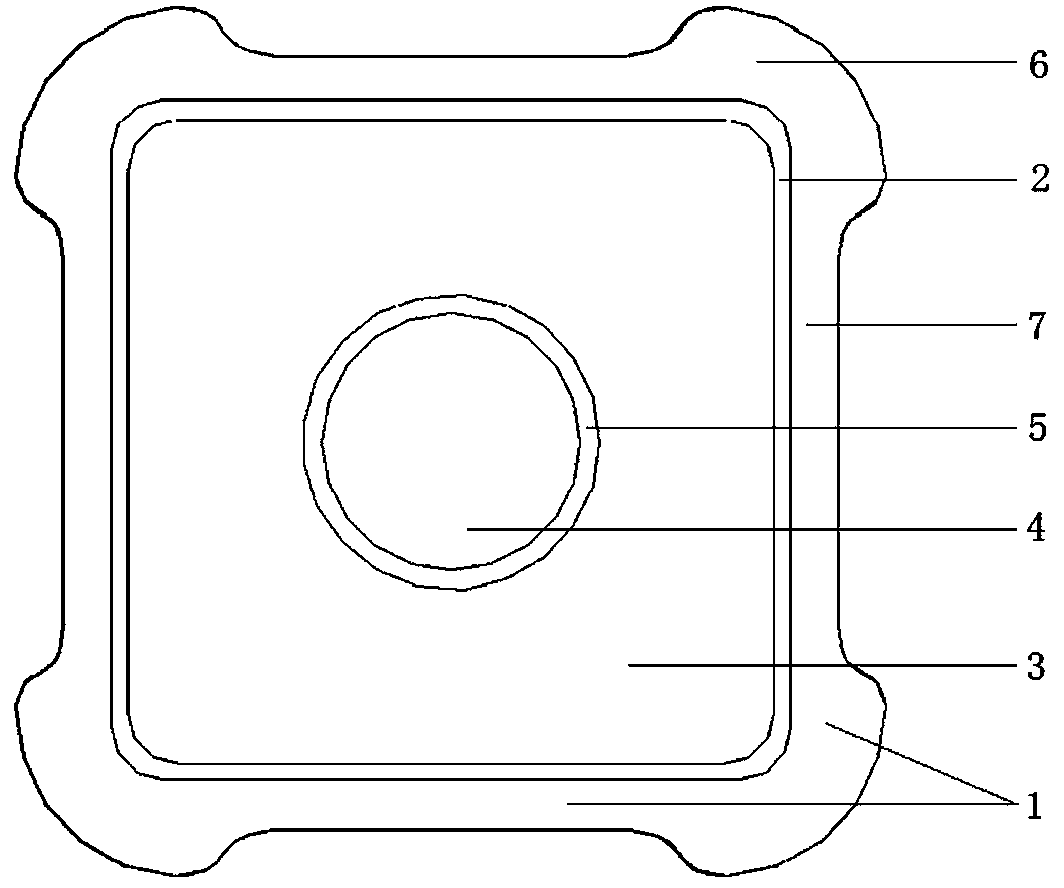

[0025]A solar water heater connected tank liner seal head composition structure includes a horizontal edge protection 1, a longitudinal receiving edge 2, a cover 3, a water pipe installation opening 4, and an external extension diameter 5 of the water pipe installation opening. The shape of the cover 3 is circular. The periphery of the cover 3 is provided with a longitudinal receiving edge 2, and the longitudinal receiving edge 2 and the cover 3 have an inclination angle of 1°. The horizontal edge protection 1 is arranged on the top of the longitudinal receiving edge 2, and the horizontal edge protection 1 is a ring configuration. , the ring-shaped middle space is composed of a horizontal edge 1 and a cover 3, and the horizontal edge 1 is composed of an ear 6 and an edge 7, and the width of the edge 7 is smaller than that of the ear 6 to ensure easy operation during installation and reduce the use of material, the horizontal edge protection 1 is parallel to the cover 3, a water...

Embodiment 2

[0028] A solar water heater connected tank liner seal head composition structure includes a horizontal edge protection 1, a longitudinal receiving edge 2, a cover 3, a water pipe installation opening 4, and an external extension diameter 5 of the water pipe installation opening. The shape of the cover 3 is rectangular. The periphery of the cover 3 is provided with a longitudinal receiving edge 2, and the longitudinal receiving edge 2 and the cover 3 have an inclination angle of 3°. The horizontal edge protection 1 is arranged on the top of the longitudinal receiving edge 2, and the horizontal edge protection 1 is in a ring configuration. The annular middle space is composed of a horizontal edge protection 1 and a cover 3. The horizontal edge protection 1 is composed of an ear protection 6 and an edge protection 7. The width of the protection edge 7 is smaller than that of the protection ear 6 to ensure easy operation during the installation process and also reduce material consu...

Embodiment 3

[0031] A solar water heater connected tank liner seal head composition structure includes a horizontal edge protection 1, a longitudinal receiving edge 2, a cover 3, a water pipe installation opening 4, and an external extension diameter 5 of the water pipe installation opening. The shape of the cover 3 is rectangular. The periphery of the cover 3 is provided with a longitudinal receiving edge 2, and the longitudinal receiving edge 2 and the cover 3 have an inclination angle of 3°. The horizontal edge protection 1 is arranged on the top of the longitudinal receiving edge 2, and the horizontal edge protection 1 is in a ring configuration. The annular middle space is composed of a horizontal edge protection 1 and a cover 3. The horizontal edge protection 1 is composed of an ear protection 6 and an edge protection 7. The width of the protection edge 7 is smaller than that of the protection ear 6 to ensure easy operation during the installation process and also reduce material consu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com