Electric motor for built-in recycling compressor

A circulating compressor, built-in technology, applied in the field of electric motors, can solve the problems of reducing ground resistance, wasting energy, poor contact, etc., to achieve the effect of eliminating oil and air, simple connection structure, and preventing phase-to-phase heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

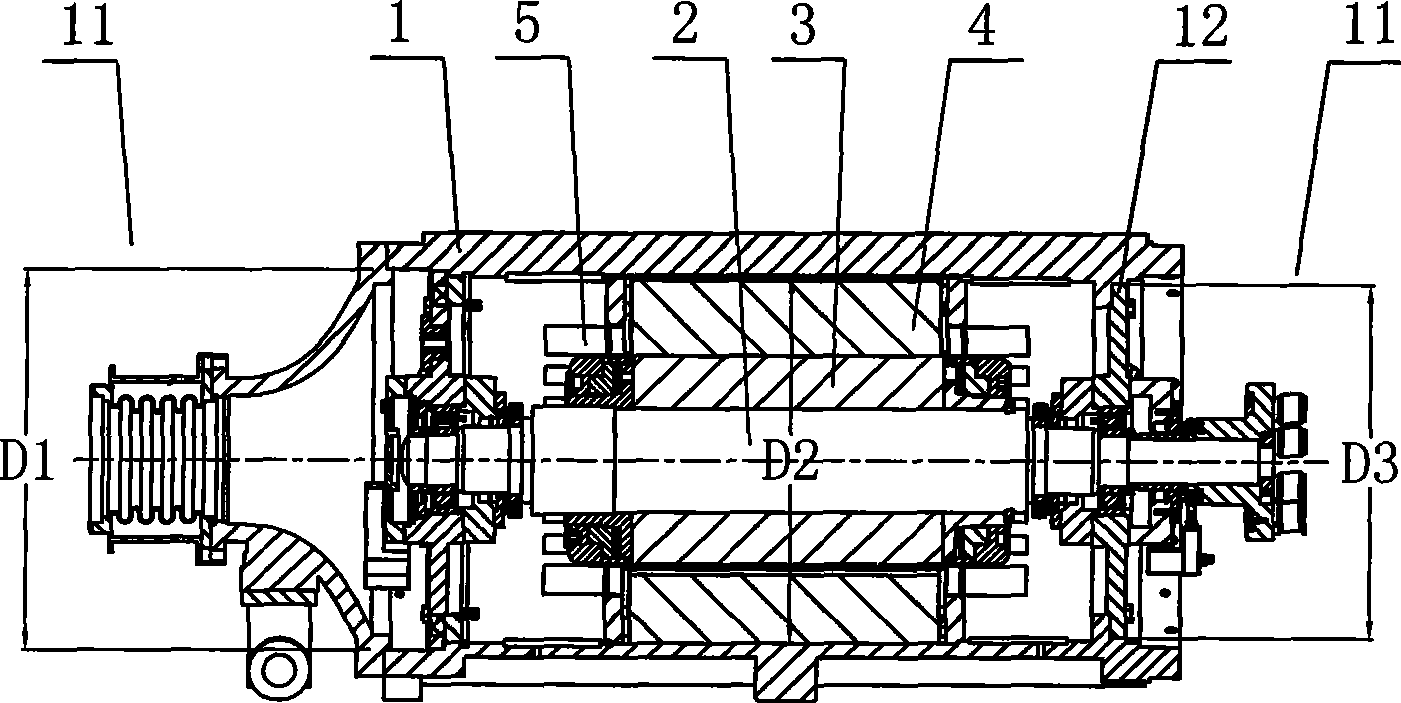

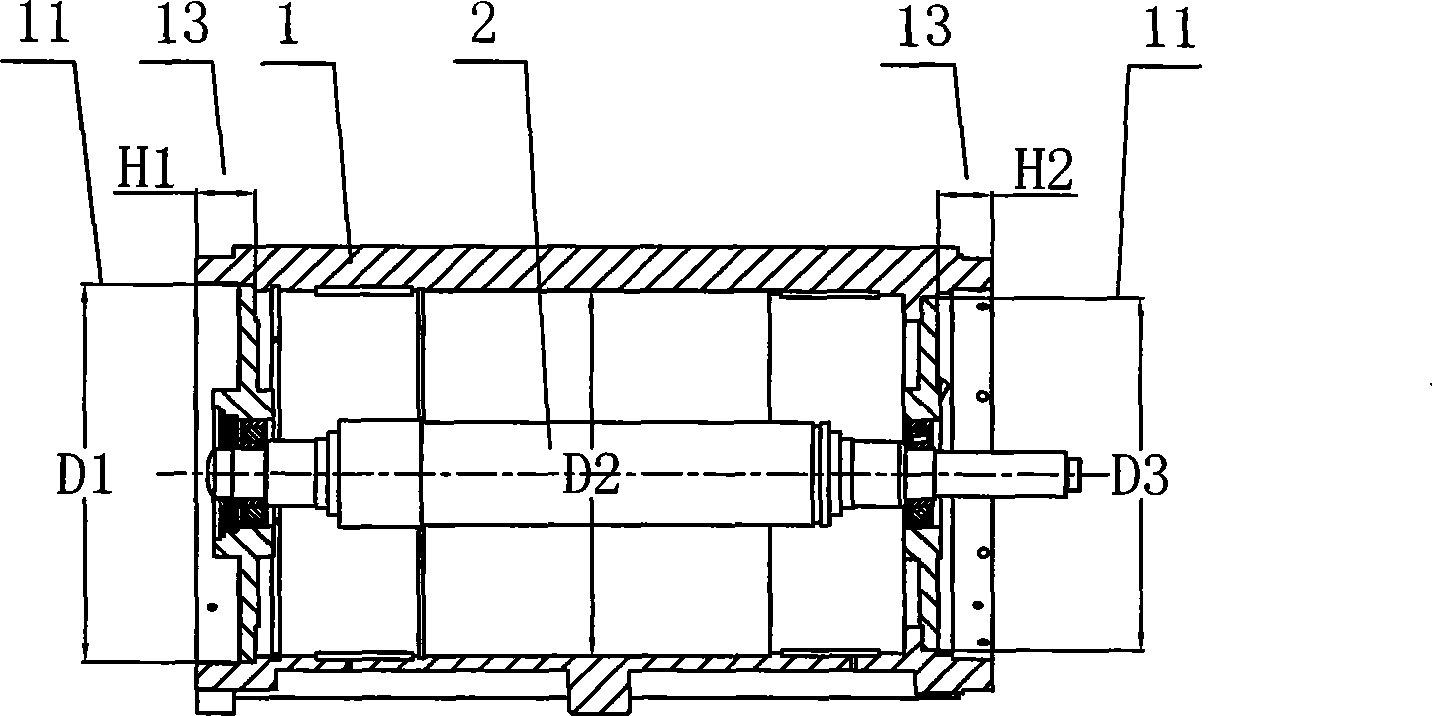

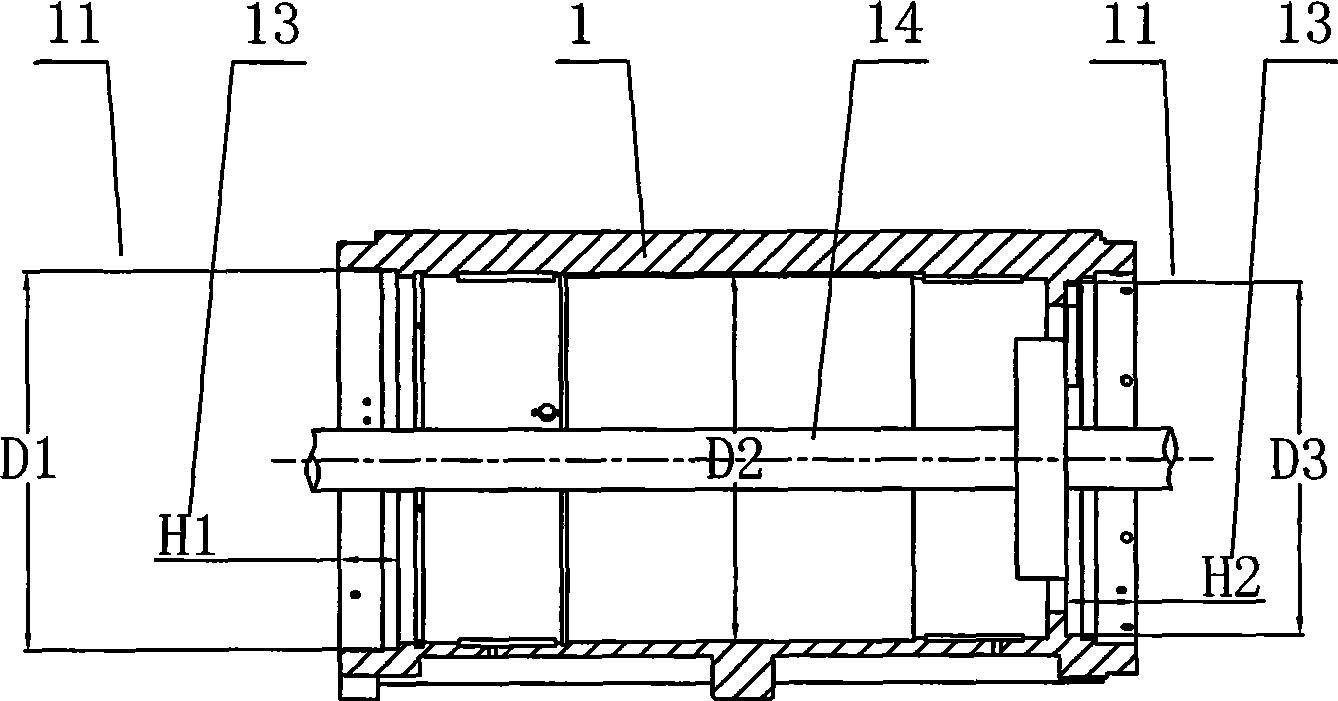

[0029] Referring to the accompanying drawings, a motor for a built-in circulating compressor mainly includes a housing 1, a rotating shaft 2, a rotor core 3, a stator core 4 and a coil 5, especially between the upper and lower windings 6 of the coil 5. Connectors 7 and isolation spacing S8 are provided at the connection. After the side ends of the winding 6 are connected and fixed with the connector 7, the isolation distance S between the upper and lower layers of the coils 5 embedded in the magnetic slot of the stator core 4 naturally forms an annular spacing area centered on the rotating shaft. The separation distance S is 8-15mm, and the determination of the size of S is related to the pitch setting of the stator winding. The annular space area enables a heat dissipation space between the upper and lower windings 6 of the coil 5, and makes the connection structure of the winding 6 simpler, more scientific and effective. Prevent the occurrence of motor phase heating, short c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com