Formation and construction set for continuous open-cut tunnel

A technology for construction equipment and tunnels, applied in tunnels, tunnel linings, mining equipment, etc., can solve the problems of complicated demoulding process, poor integrity, low construction efficiency, etc., to save engineering materials and labor costs, lining surface quality, The effect of improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

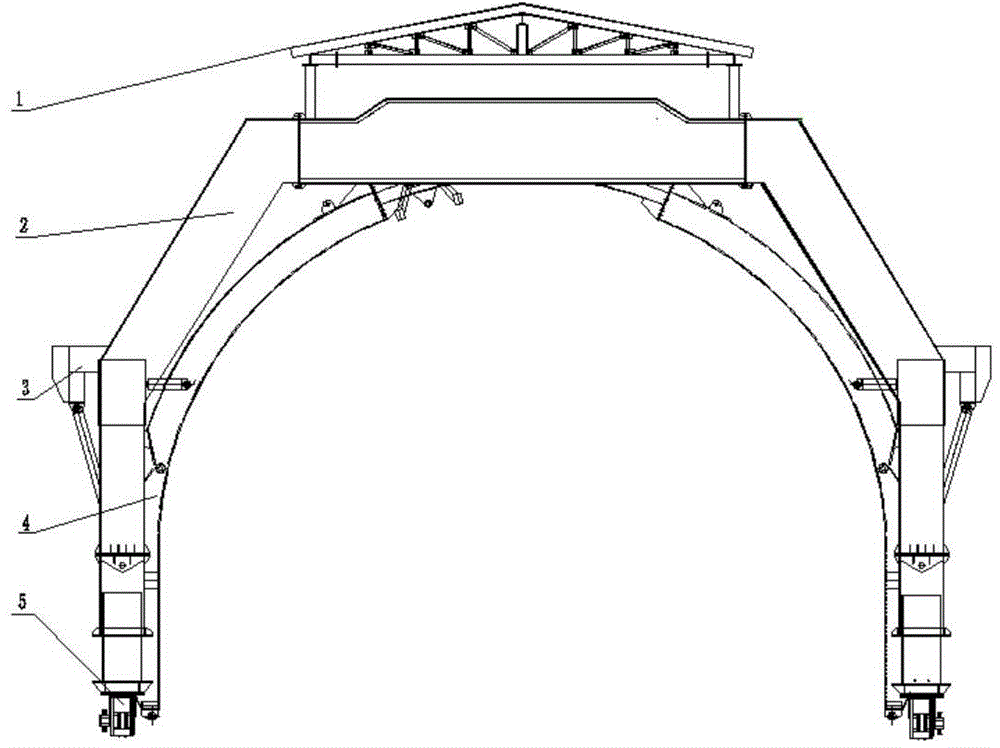

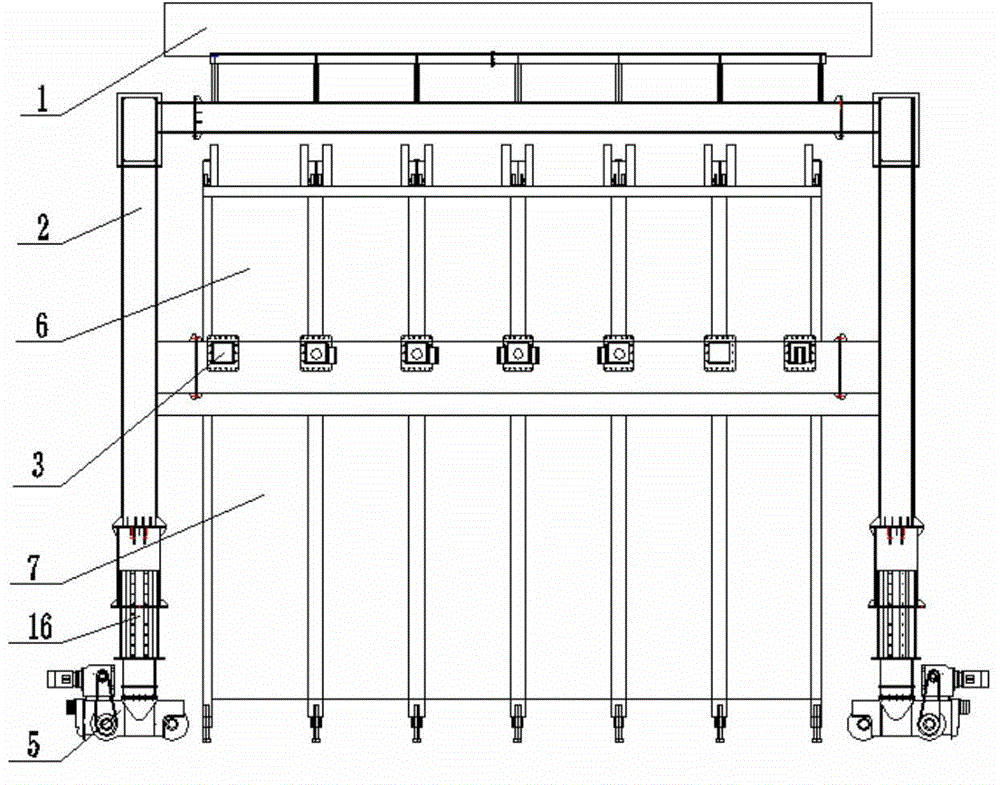

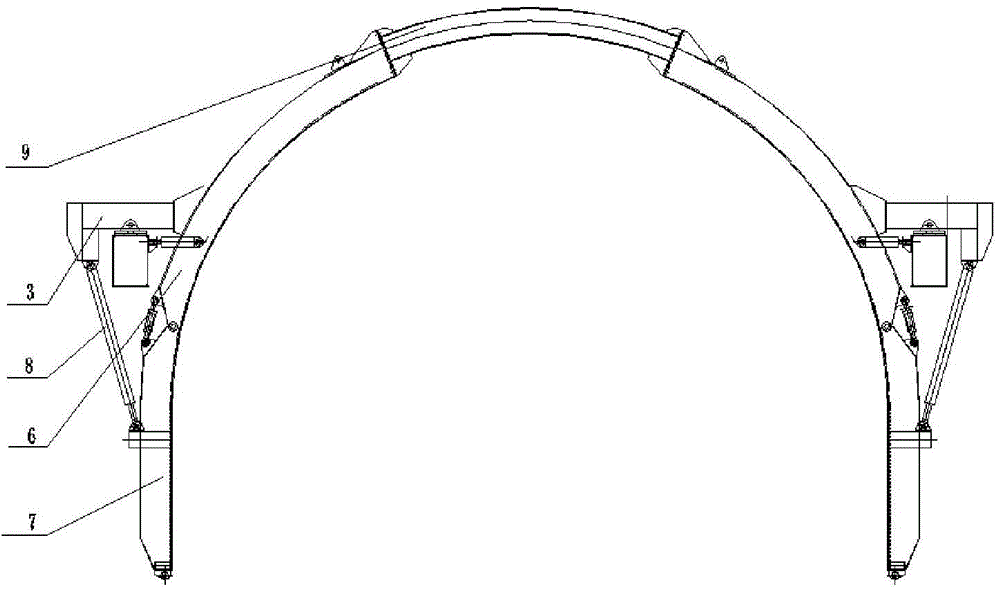

[0031] Such as Figure 1 to Figure 10 As shown, it includes frame, formwork, running mechanism, mechanical support, roof and hydraulic electric control system.

[0032] The vehicle frame is composed of two door frames, longitudinal beams and telescopic columns. Four hydraulic oil cylinders are horizontally fixed on the upper side of the vehicle frame.

[0033] One end of the four hydraulic cylinders is connected with the door frame, and the other end is connected with the formwork system. By adjusting the expansion and contraction of the oil cylinders in the diagonal direction, the formwork can be adjusted horizontally.

[0034] The two portal frames are connected together by longitudinal beams, and the longitudinal beams are connected together with the formwork through mechanical supports.

[0035] The mechanical support is composed of 7 telescopic oil cylinders fixed on the longitudinal beam, and the other end is fixed on the formwork through a pin shaft.

[0036] The for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com