Roundabout cooling and filtering type engine oil cooler

A technology of engine oil and cooler, which is applied in the direction of engine cooling, engine components, engine lubrication, etc. It can solve the problems of increasing the storage capacity of engine oil, reducing the temperature of engine oil, and the cleanliness of engine oil is not high, so as to increase the sedimentation time of impurities , increase the flow path, improve the effect of heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific embodiment of the present invention is described in detail below in conjunction with accompanying drawing:

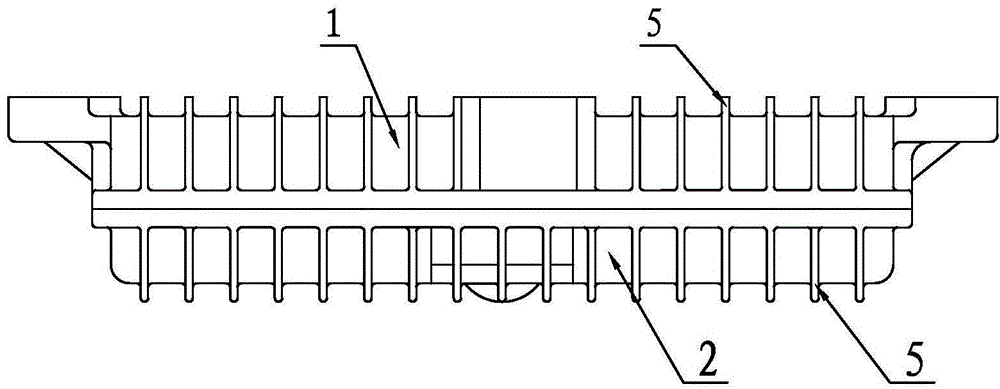

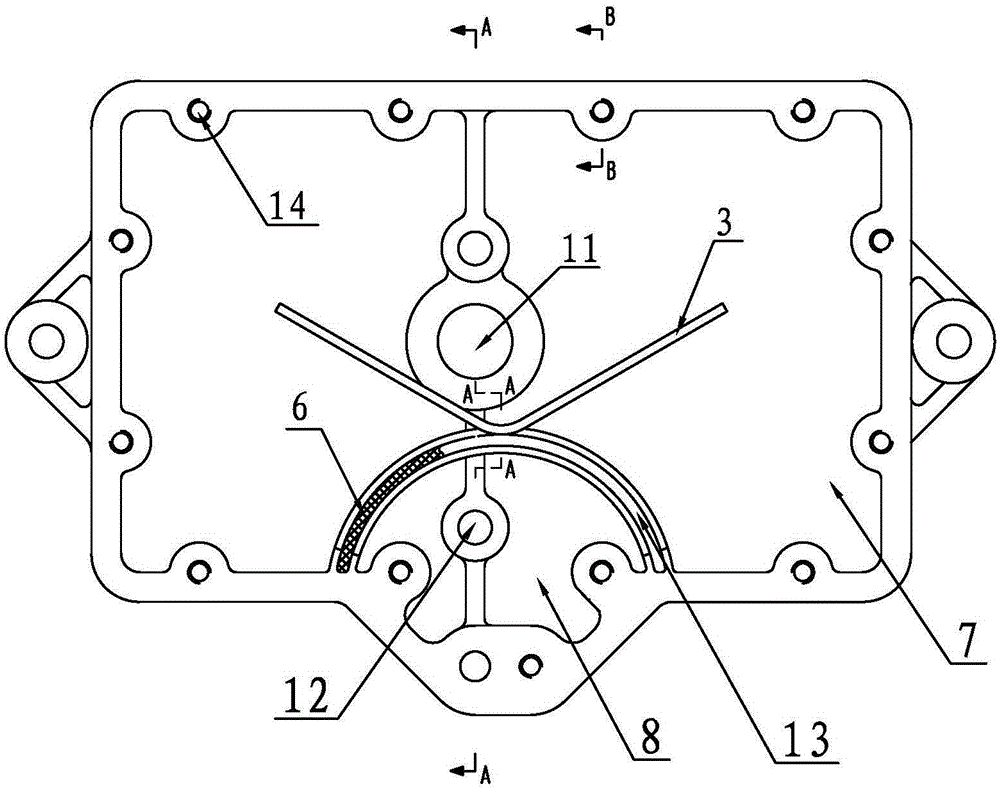

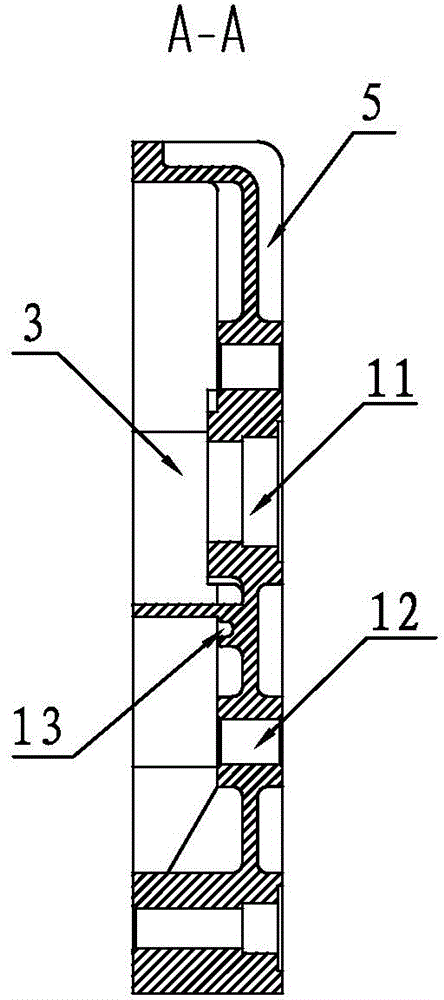

[0026] A detour cooling filter type engine oil cooler, such as Figure 1-7As shown, it includes an upper case 1, a lower case 2, an upper backflow guide embankment 3, a lower backflow guide embankment 4 and a cooling fin 5, the upper case 1 and the lower case 2 are cuboids with one end open, and the upper case 1 Four threaded holes 14 are respectively equidistantly arranged on the two long sides of the opening connection end face of the upper casing 1, and two threaded holes 14 are respectively equidistantly arranged on the two short sides of the opening connection end surface of the upper housing 1. There is a through hole 24 at the position corresponding to the threaded hole 14 on the open connection end face of 2. The aperture of the through hole 24 is larger than the nominal diameter of the threaded hole 14. The bolt passes through the through ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com