Circular divided blasting tunnel construction method capable of effectively controlling blasting vibration velocity

A technology for controlling blasting and tunnel construction, which is applied in blasting and other directions, and can solve problems such as under-blasting, difficulty in achieving controlled blasting effects, and excessive blasting vibration speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

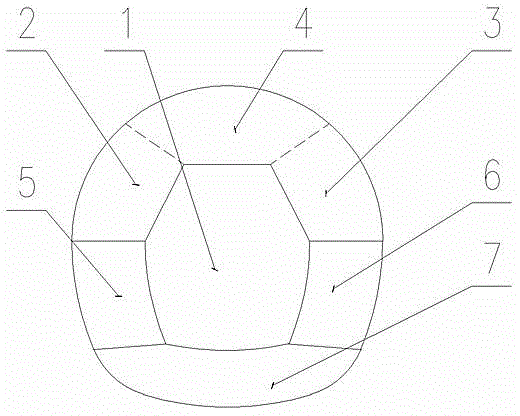

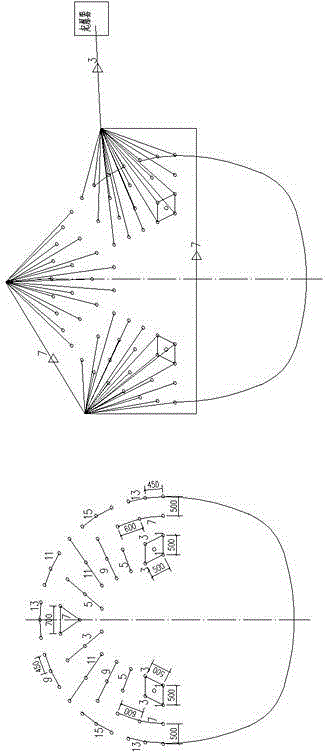

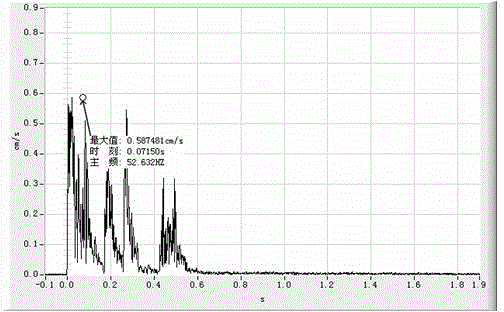

[0017] The specific implementation manner of the present invention will be described below with reference to the accompanying drawings. Such as Figure 1 to Figure 5 Shown: A tunnel construction method of ring-directed staged blasting that can effectively control the blasting vibration velocity, according to the following steps:

[0018] a. First determine the outer contour circle of the tunnel to be constructed by blasting, and then divide the outer contour circle into 360° clockwise with the 12 o'clock direction as 0 o'clock, and keep the upper part of the outer contour circle under the condition of retaining the central rock layer 1. The stepped part is detonated once. First, the left part 2 from 270° to 330° is subjected to the first-zone out-of-hole differential blasting, and then the right side part 3 from 30° to 90° is subjected to the second zone out-of-hole differential blasting. Finally, carry out the micro-differential blasting outside the hole in the third area on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com