Integrated thin film sensor for measuring surface heat flow rate in hypersonic flow

A thin-film sensor and hypersonic technology, applied in the field of integrated sensors, can solve the problems of difficult control of the connection error between the sensor and the metal model, poor integrity of measurement data, and difficulty in intensive measurement, so as to ensure accuracy, improve measurement data accuracy, and integration. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the above objects, features and advantages of the present invention more comprehensible, specific implementations of the present invention will be described in detail below in conjunction with the accompanying drawings.

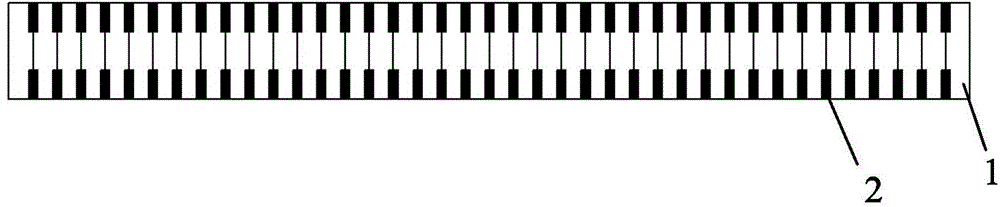

[0024] see figure 2 and image 3 , the present invention provides an integrated thin-film sensor for measuring surface heat flow rate in hypersonic flow, comprising: a glass substrate, which is a whole, and is a flat plate; and a temperature measuring element group, each temperature measuring element is included in the A metal film prepared by a coating process in a certain area of the glass substrate. Adjacent metal films are separated from each other by a certain distance. All the metal films are arranged regularly and have the same resistance temperature characteristics. The material of the metal film is platinum.

[0025] The integrated film sensor designed by the invention can satisfy the measurement of the surface heat flow ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com