A corrosion fatigue crack growth test device

A crack growth test and corrosion fatigue technology, which is applied in the direction of measuring devices, weather resistance/light resistance/corrosion resistance, wear resistance testing, etc., can solve problems such as solution leakage, and achieve the effect of easy operation, volume reduction, and vertical loading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

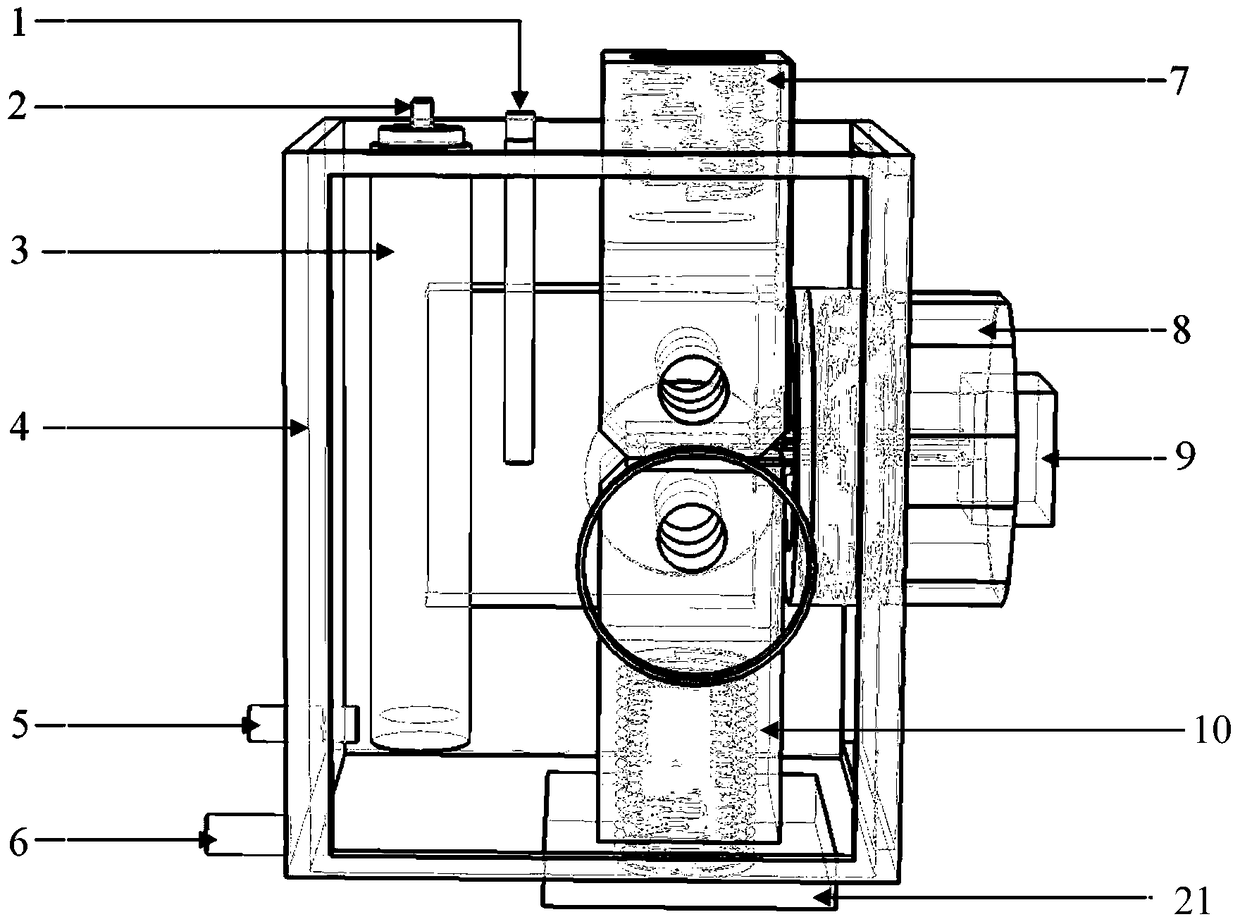

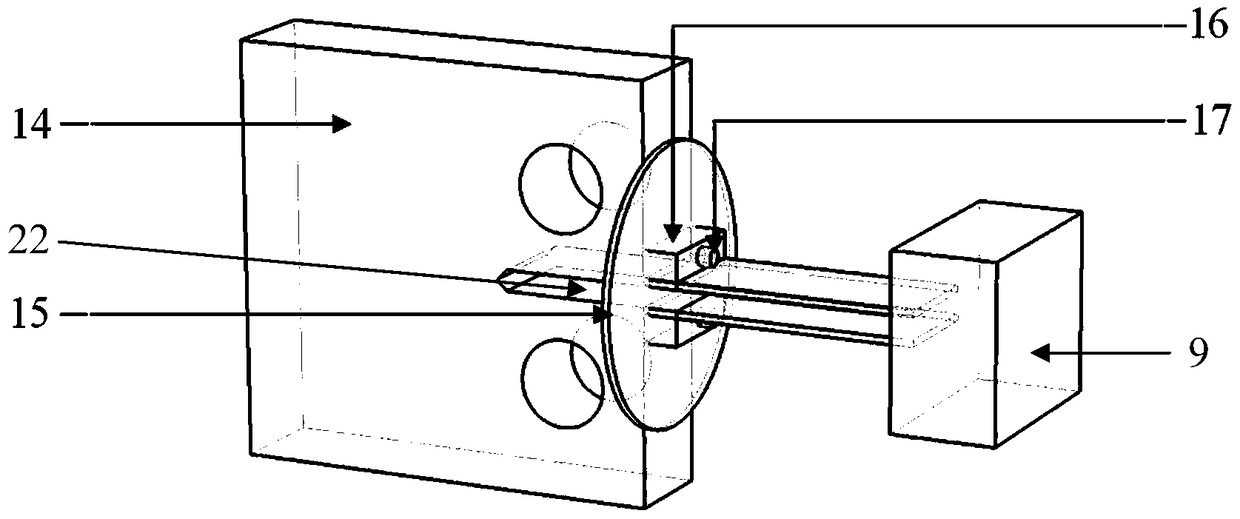

[0033] like Figure 1 to Figure 4 As shown, the corrosion fatigue crack growth test device of this embodiment includes a load application system, a crack detection system and a temperature control system. The specific structure and use process are as follows:

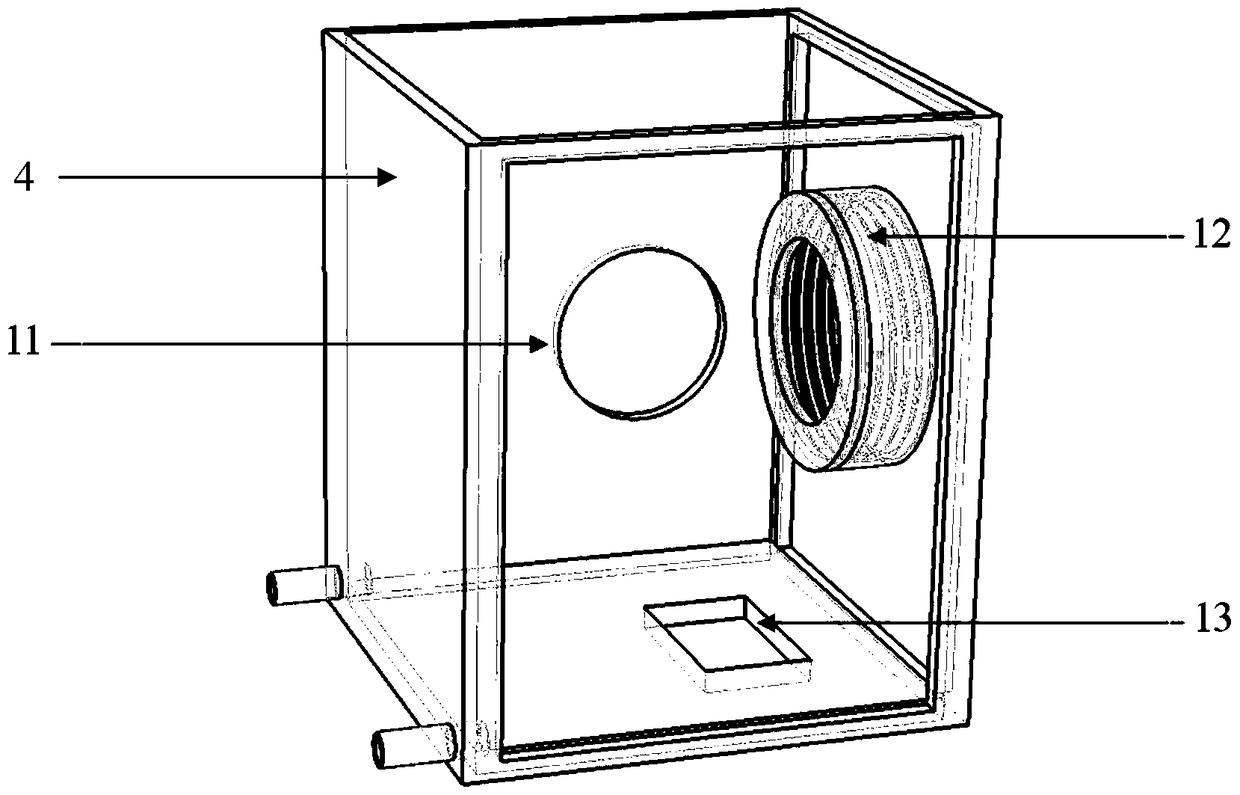

[0034] The load application system is equipped with an upper U-shaped fixture 7 and a lower U-shaped fixture 10 with a raised platform for loading the CT sample 14; the lower U-shaped fixture 10 has a raised platform 21 for carrying the environmental box 4 (plexiglass) , the boss 21 is loaded from the lower U-shaped clamp installation port 13 on the bottom surface of the environmental box 4 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com