Touch control display substrate

A technology of touch display substrate and touch scanning, which is applied in the direction of static indicators, optics, instruments, etc., can solve the problems of reducing accuracy and setting time difference of touch effect detection, so as to reduce the difference and improve the accuracy , the effect of difference reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

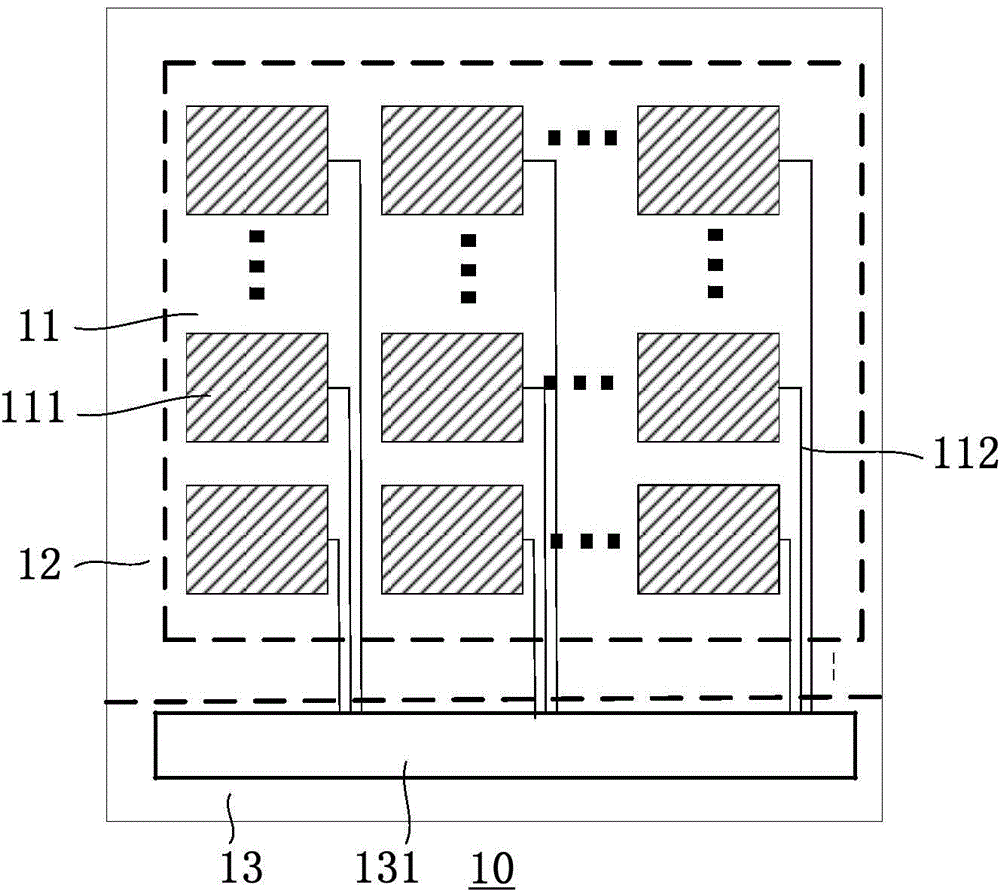

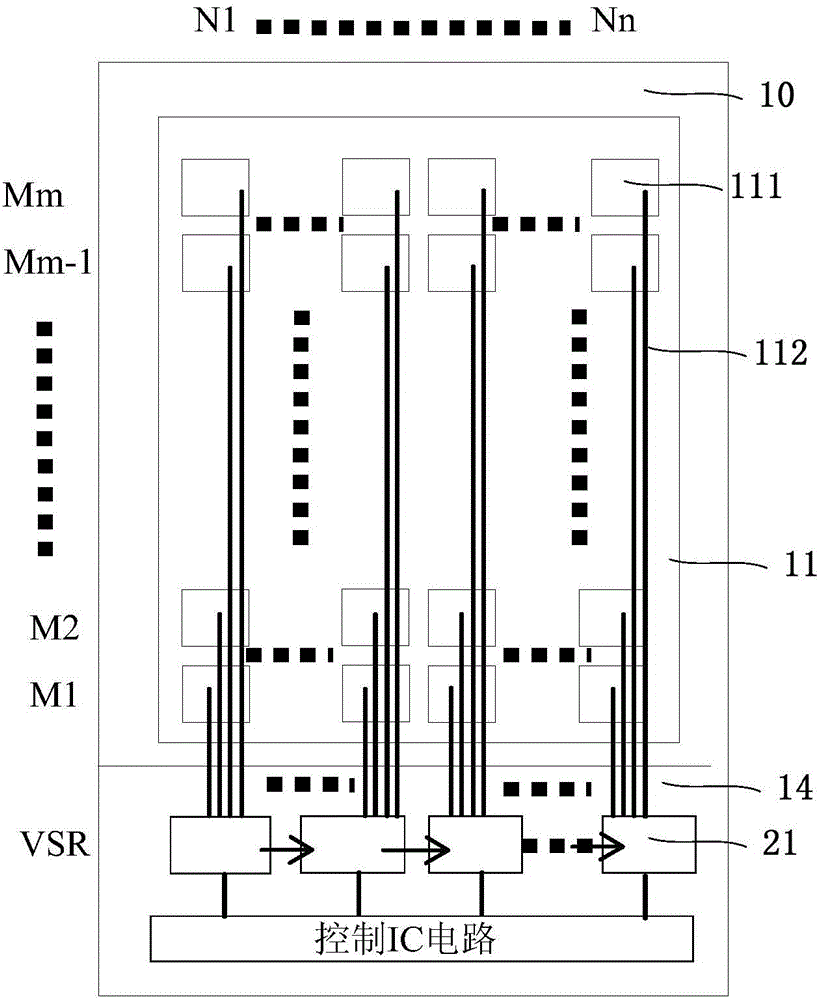

[0043] Embodiment 1 of the present invention provides a touch display substrate. figure 2 It is a structural diagram of the touch display substrate provided by Embodiment 1 of the present invention.

[0044] Such as figure 2 As shown, the touch display substrate includes:

[0045] A substrate 10, including a display area 11 and a non-display area 14;

[0046] A plurality of common electrode blocks 111 arranged at intervals, the common electrode blocks 111 form an array of M rows*N columns, and the common electrode blocks 111 are multiplexed as touch electrodes;

[0047] A plurality of wires 112, each wire 112 is electrically connected to a common electrode block 111;

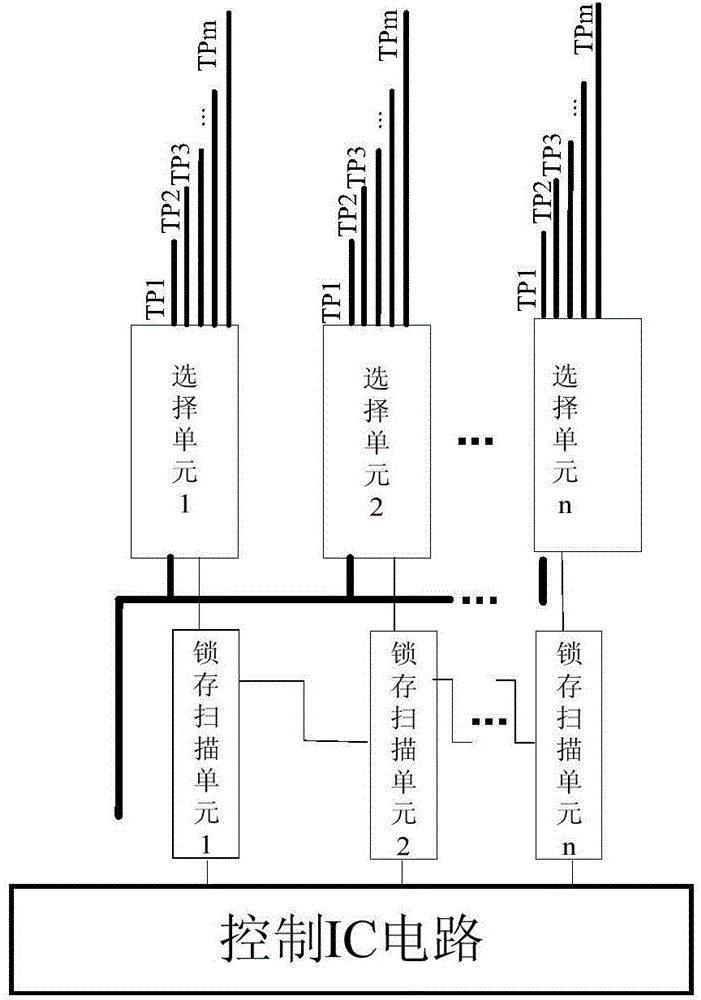

[0048]A vertical shift circuit, arranged in the non-display area 14 and electrically connected to the wiring 112, the vertical shift circuit includes a plurality of cascaded vertical shift circuit units 21, each vertical shift circuit unit 21 is connected to the wiring 112 corresponding to a column of comm...

Embodiment 2

[0064] Embodiment 2 of the present invention provides a touch display substrate. The touch display substrate divides the common electrode block into two symmetrical common electrode block groups according to the column direction, and the control IC circuit is used to apply different frequencies to different common electrode block groups in different touch scanning time periods. scan pulse signal. Figure 6 and Figure 7 They are respectively the first state diagram and the second state diagram of different common electrode block groups applying scan pulse signals with different frequencies provided by Embodiment 2 of the present invention.

[0065] Such as Figure 6 and Figure 7 As shown, on the basis of the first embodiment, this embodiment divides the common electrode block into two symmetrical common electrode block groups in the column direction.

[0066] The control IC circuit is used to apply a scanning pulse signal of a first frequency to the first common electrode...

Embodiment 3

[0072] Embodiment 3 of the present invention provides a touch display substrate. The touch display substrate divides the common electrode block into three common electrode block groups in the column direction, and the control IC circuit is used to apply to different common electrode block groups in different touch scanning time periods. Scanning pulse signals with different frequencies. Figure 9 , Figure 10 and Figure 11 They are respectively the first state diagram, the second state diagram and the third state diagram of applying scanning pulse signals with different frequencies to different common electrode block groups provided by Embodiment 3 of the present invention.

[0073] Such as Figure 9 , Figure 10 and Figure 11 As shown, on the basis of the first embodiment, this embodiment divides the common electrode block into three common electrode block groups divided into three equal parts in the column direction.

[0074] The control IC circuit is used to apply a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com