Full digitalization LED lighting source driving control system and technical scheme

A technology of LED lighting and light source driving, applied in the direction of light source, electric light source, lighting device, etc., can solve the problem of multi-channel independent constant current driver not working normally, the working voltage of multi-channel independent constant current driver is not enough, unable to work normally, etc. Achieve high stability, improve service life, and achieve color effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to better understand the technical solutions of the present invention, the embodiments provided by the present invention will be described in detail below in conjunction with the accompanying drawings.

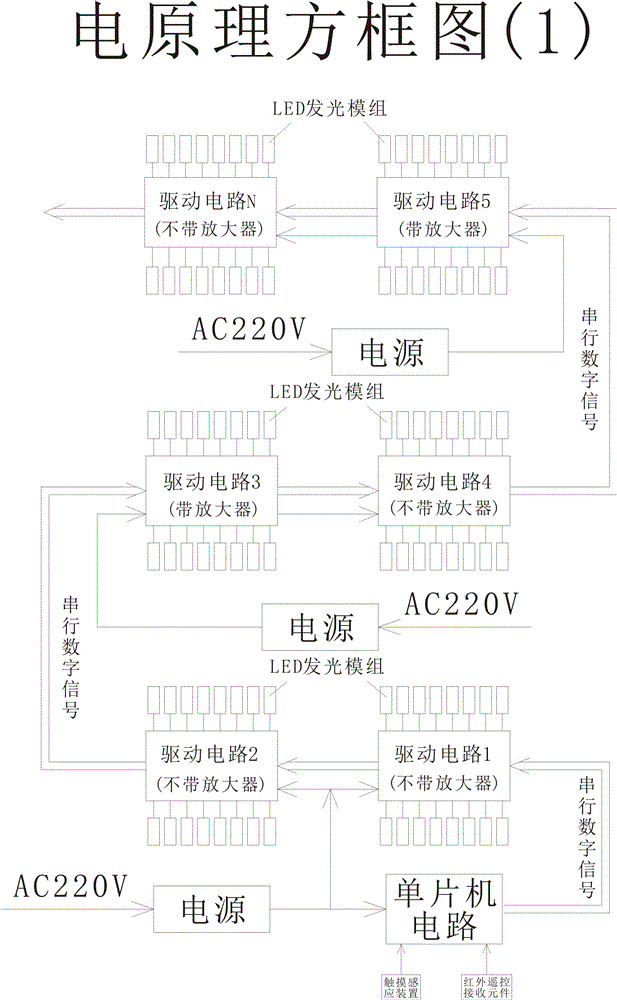

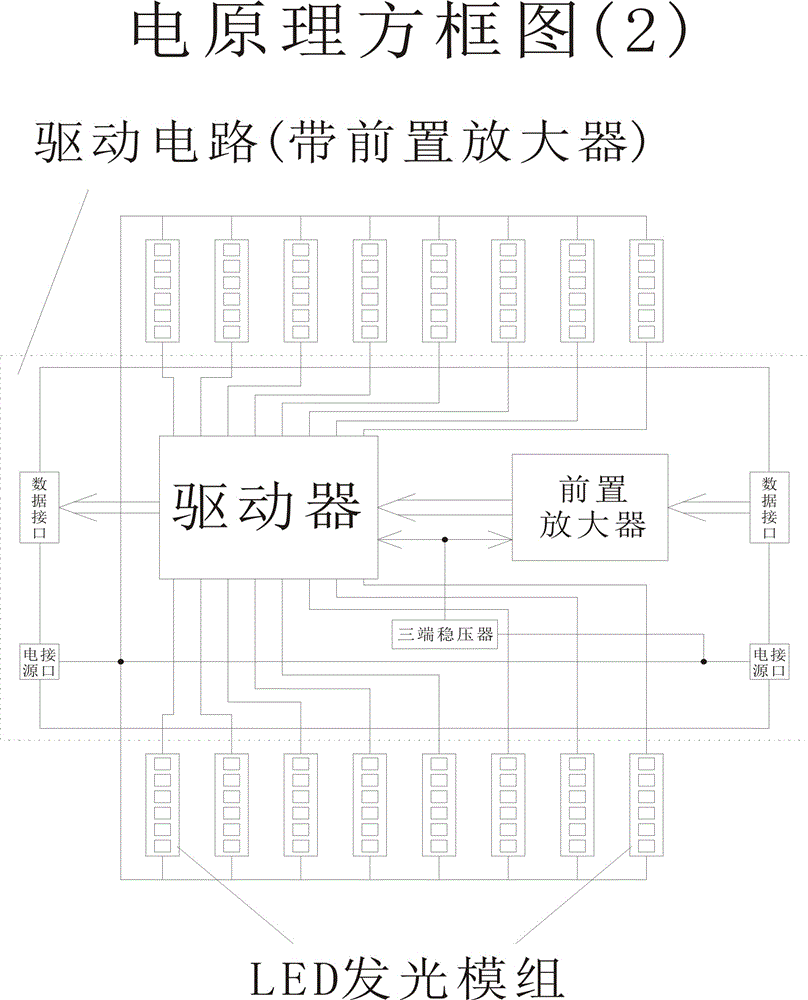

[0022] 1. Rudian principle box figure 1 As shown, the microcontroller circuit outputs programmed serial digital signals to control drive circuit 1, drive circuit 2, ... drive circuit N. Preferably, each of the driving circuits is composed of a pre-signal amplifier (or not installed), a driver, a three-terminal voltage regulator, and data, power input, and output connectors, see the electrical principle box figure 2 shown.

[0023] 2. Rudian Principle Box figure 1 As shown, each driving circuit can drive a plurality of LED light emitting modules connected in series (or a plurality of LED light emitting modules connected in common anode), such as 16. Preferably, each of the LED light-emitting modules has a plurality of LED lamp beads connected in series on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com