Cover glass for solar cell, and solar cell module

A solar cell and glass technology, applied in the direction of photovoltaic modules, supporting structures and circuits of photovoltaic modules, can solve problems such as artificial increase, and achieve the effect of ensuring strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

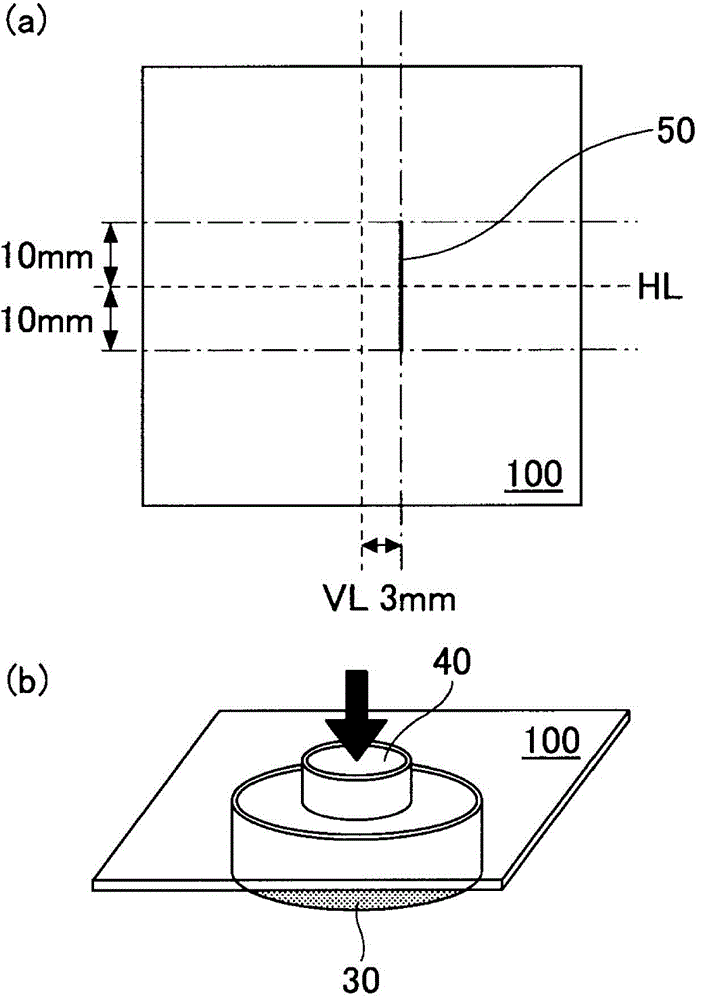

[0083] Glass plates for solar cell cover glasses shown in Table 1 below were prepared. In the table, Example 1 is a glass plate of the cover glass of the present invention, and Examples 2 to 4 are glass plates of comparative examples.

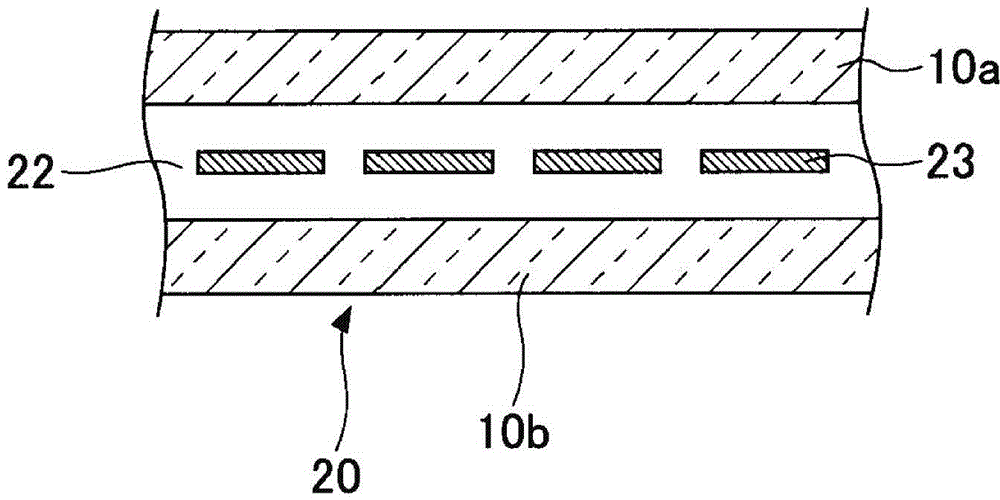

[0084] The glass plates of Examples 1 and 2 are chemically strengthened glass plates. The type of glass plate in Example 1 is LEOFLEX (registered trademark) manufactured by Asahi Glass Co., Ltd. (Asahi Glass Co., Ltd.), and the physical properties of each reinforcement obtained by chemical strengthening treatment were adjusted to those shown in the "Example 1" column of Table 1. value. The type of the glass plate of Example 2 is soda lime glass, and each strengthening physical property obtained by chemical strengthening process was adjusted to the value shown in the column of "Example 2" of Table 1. As reinforcement properties, the surface compressive stress CS (unit: MPa) of the main surface and the thickness DOL of the compressive stress la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com