Processing method for chrysanthemum tea

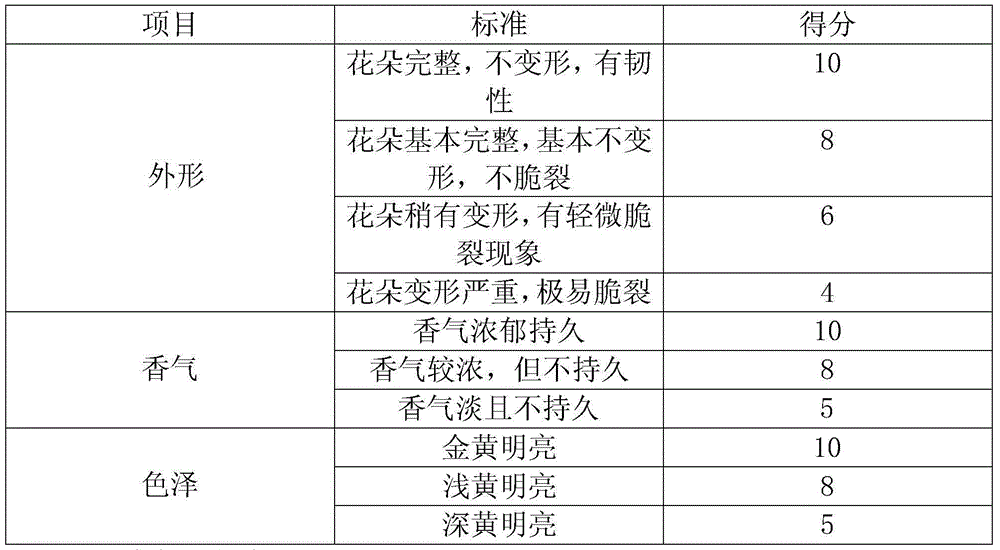

A processing method and chrysanthemum tea technology, applied in the field of chrysanthemum tea processing, can solve the problems of chrysanthemum petals that are prone to shrinkage or fragmentation, poor mechanical strength of cell walls, and flowers that cannot be fully unfolded, etc., and achieve good viewing effects, enhanced aroma and The effect of color and toughness enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] 1) Preparation of beet juice: juice the beets and dilute the original juice by 100 times to obtain beet juice.

[0018] 2) Pre-harvest treatment: When the chrysanthemum enters the flowering stage, spray beet juice on the flower buds once a day, 50kg / mu each time.

[0019] 3) Harvest: Harvest when the tubular inflorescence spreads to 2 / 3.

[0020] 4) Drying: vacuum freeze drying the harvested chrysanthemum to a moisture content of 7%, which is chrysanthemum tea.

Embodiment 2

[0022] 1) Preparation of beet juice: juice the beets, and dilute the original juice by 500 times to obtain beet juice.

[0023] 2) Pre-harvest treatment: when chrysanthemums enter the flowering stage, spray beet juice on the flower buds, once every ~4 days, and spray 200kg / mu each time.

[0024] 3) Harvest: Harvest when the tubular inflorescence spreads to 2 / 3.

[0025] 4) Drying: drying the harvested chrysanthemum in an oven to a moisture content of 8%, that is, chrysanthemum tea.

Embodiment 3

[0027] 1) Preparation of beet juice: juice the beets, and dilute the original juice by 250 times to obtain beet juice.

[0028] 2) Pre-harvest treatment: on the 1st to 20th day after the chrysanthemum enters the flowering period, spray beet juice every 3 days, 50kg / mu each time; on the 21st to 40th day when the chrysanthemum enters the flowering period, spray every day Once beet juice, spray 120kg / mu each time.

[0029] 3) Harvest: Harvest when the tubular inflorescence spreads to 2 / 3.

[0030] 4) Drying: vacuum freeze drying the harvested chrysanthemum to a moisture content of 7%, which is chrysanthemum tea.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com