Numerical control roll machine

A technology of rolling mill and numerical control system, which is applied in the field of metal rolling, can solve the problems of unstable rotation accuracy of the output shaft, unstable quality of processed workpieces, and inability to satisfy users, etc., and achieve constant-speed feed, precise positioning, and return clearance The effect of small size and high transmission precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

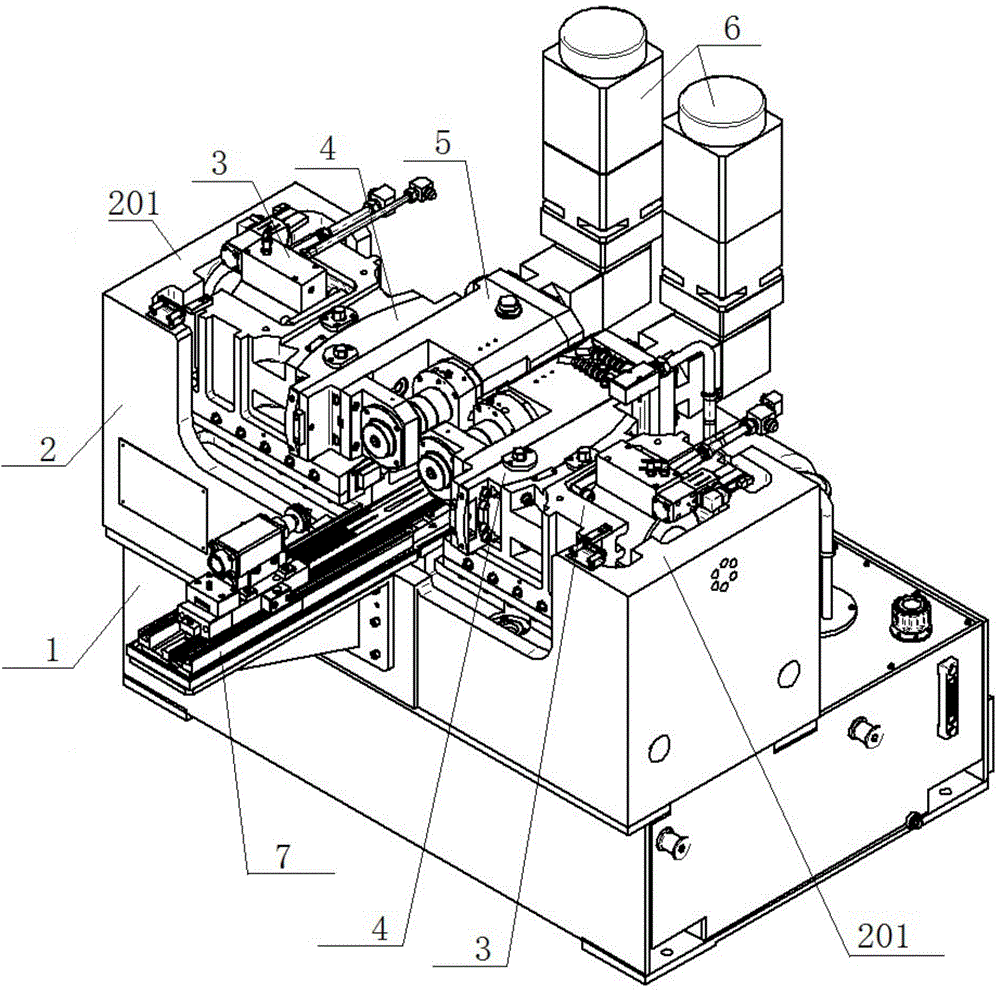

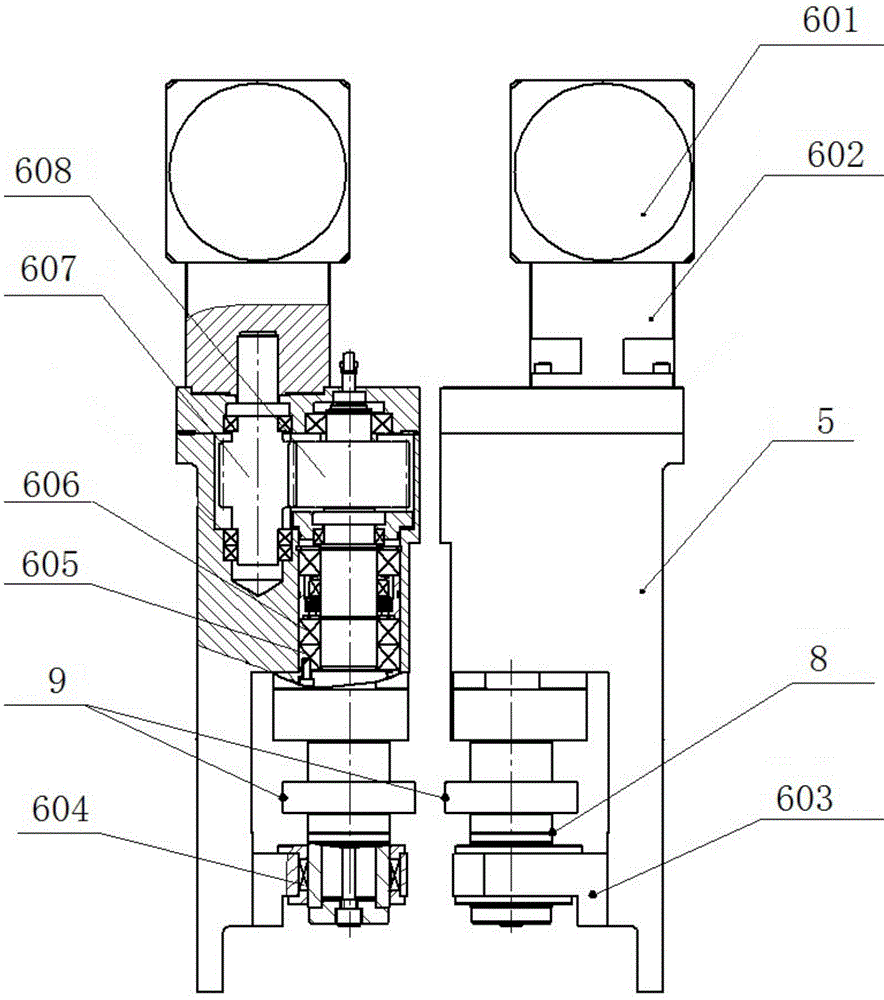

[0021] The numerically controlled rolling mill includes a machine body, a servo spindle system 6, a proportional servo hydraulic slide feed system and a numerically controlled system. Wherein the fuselage comprises an upper fuselage 2 and a lower fuselage 1, the servo spindle system 6, the proportional servo hydraulic slide feed system and the numerical control system and the upper fuselage are all fixed on the lower fuselage. At the same time, a fixture 7 is provided in the middle of the fuselage, and the workpiece is arranged on the fixture 7, and the axial position is adjustable, and the fixture is arranged along a horizontal direction perpendicular to the fuselage. The upper fuselage 2 adopts a concave casting structure, and the two ends of the upper fuselage 2 are respectively provided with fuselage side walls 201, and the fuselage side walls 201 and the upper fus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com