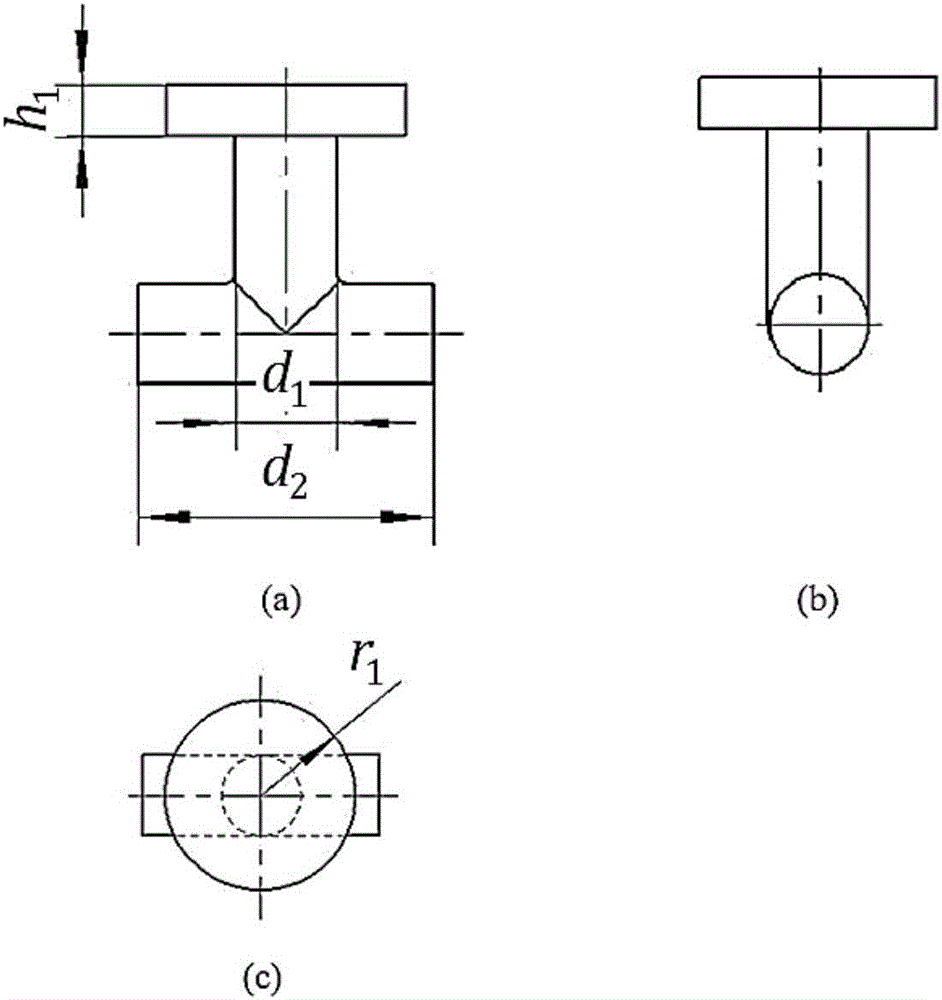

Rotary Die for H-shaped Joint and Its Forming Process

A technology of I-shape and moulds, which is applied in the direction of manufacturing tools, metal processing equipment, forging/pressing/hammer devices, etc., can solve the problems of unsuitable mass production, low material utilization rate, and difficult pre-forging design, etc., to achieve convenient The effect of controlling unit cost, stable forming process, and reducing workpiece defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

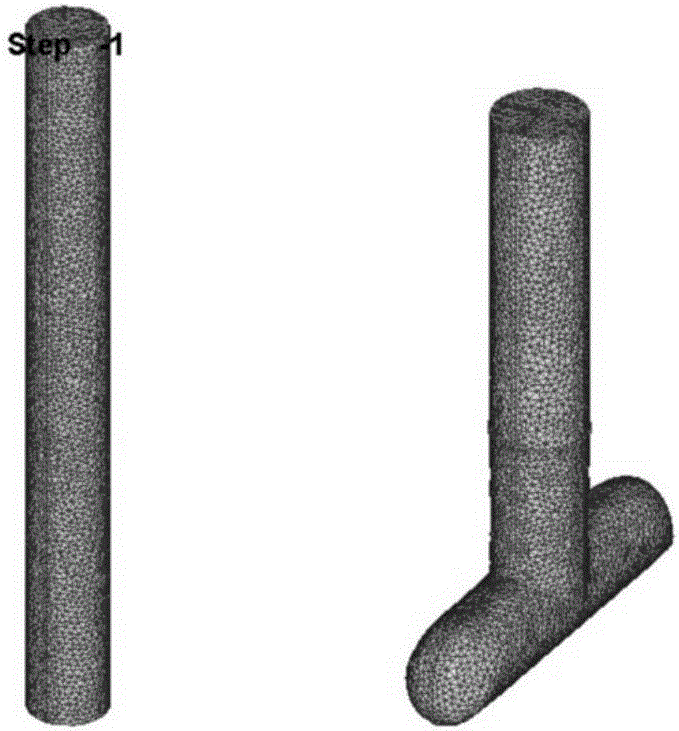

Method used

Image

Examples

Embodiment 1

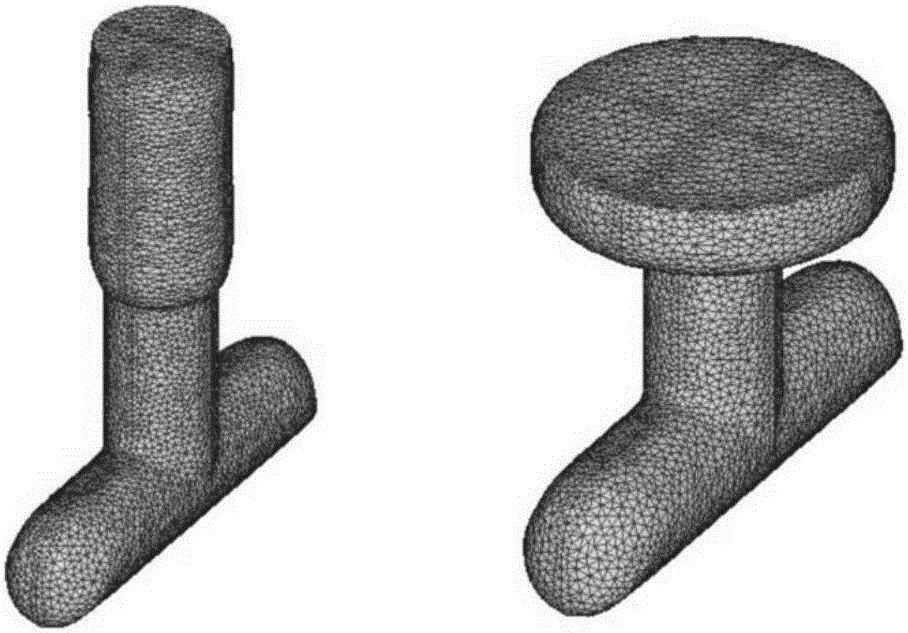

[0043] Such as Figure 3 ~ Figure 7 As shown, this embodiment includes: an extrusion punch, an upsetting punch and a final forging punch that are evenly distributed on the circular formwork 1, and a die assembly that is concentric with the circular formwork 1 and rotates. Among them: three punches share a set of die components.

[0044] The circular mold base 1 is set on the body 20, the center O of the working punch coincides with the working center of the press, and can rotate relative to the body 20 with the center O as the center.

[0045] Such as Image 6 with Figure 7 As shown, the die assembly includes: an upper die 9, a lower die 10, and a cylindrical die cavity formed when the oblique slider 8 is closed; Four push rods 11 are housed in the 10, and the upper ends of the push rods 11 are fixed on the oblique slider 8, and the outer sidewall of the oblique slider 8 has a certain inclination and satisfies

[0046] In this embodiment, the outer wall of the inclined ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com