Manipulator for cylinder production line

A production line and manipulator technology, applied in metal processing machinery parts, maintenance and safety accessories, metal processing, etc., can solve problems such as impact between the cylinder body and the manipulator surface, affecting the service life of the manipulator, and affecting the next process of the cylinder body, etc., to achieve Strong adaptability, simple structure, space-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

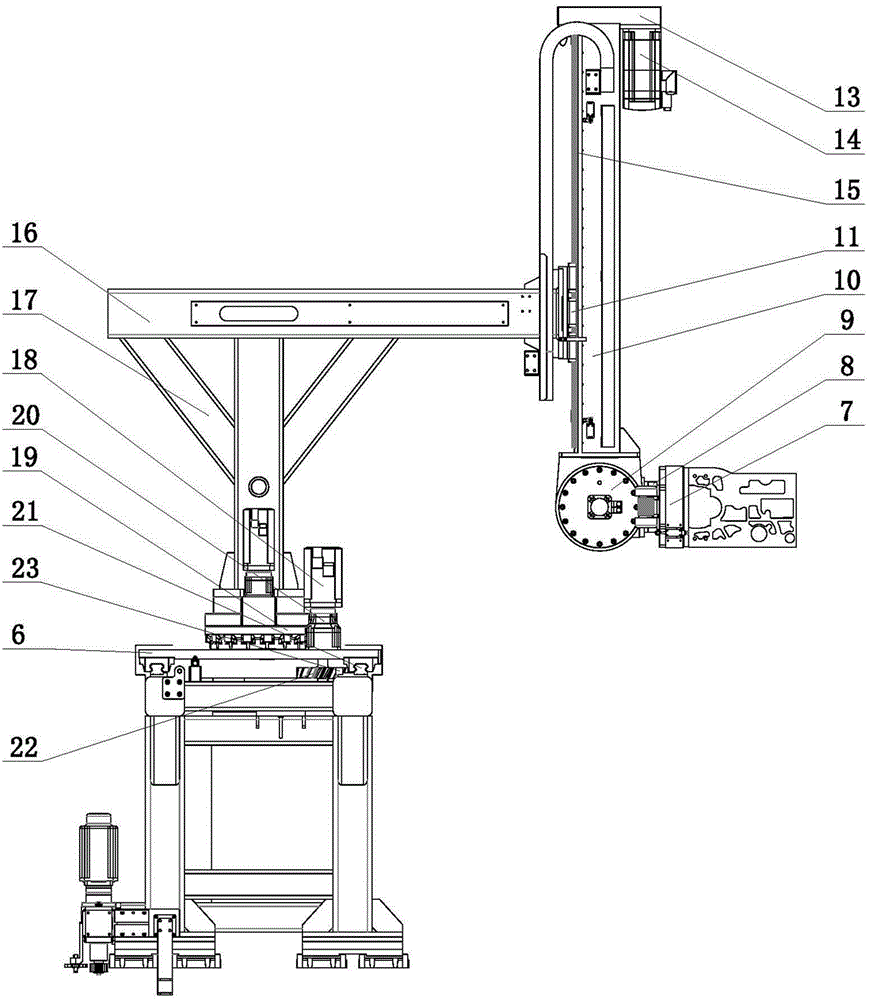

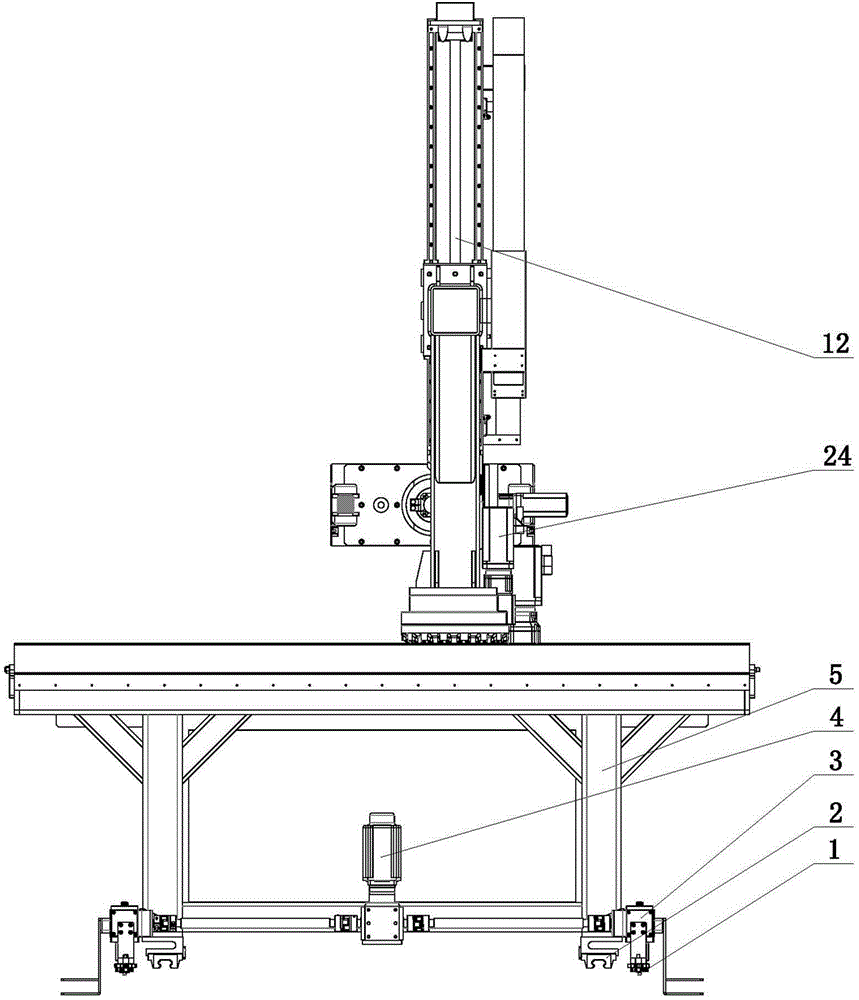

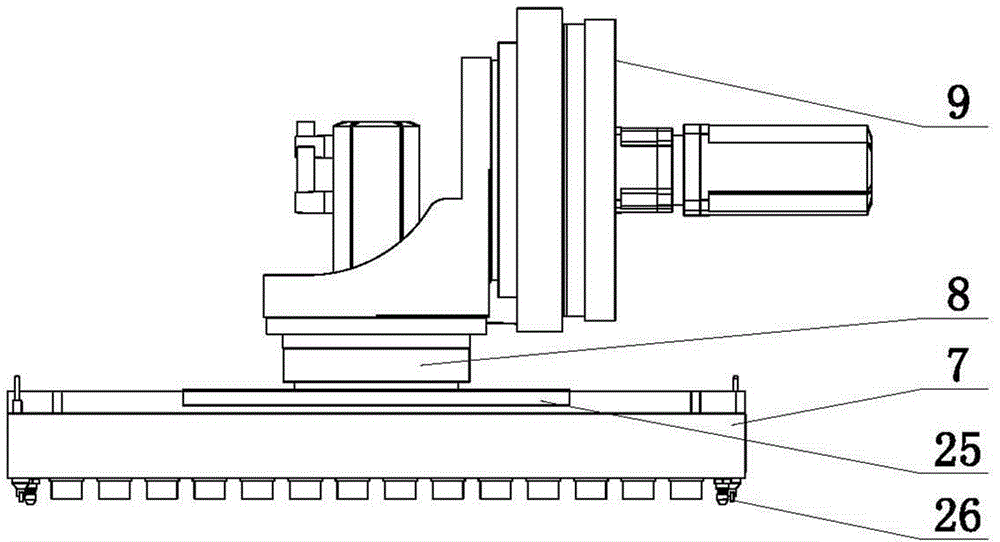

[0020] The present invention includes an X-axis transmission mechanism 3, a Y-axis support 5 is arranged on the X-axis transmission mechanism 3, and it is characterized in that: an R-axis rotation mechanism 19 is arranged on the Y-axis support 5 through a Y-axis transmission mechanism 20, and the R-axis rotation mechanism 19 A column 17 is arranged on the top, and a beam 16 is arranged on the upper end of the column 17. A Z-axis vertical lifting arm 10 is arranged on the beam 16 through a Z-axis driving mechanism 13, and a V-axis swing mechanism 9 is arranged on the lower end of the Z-axis vertical lifting arm 10. The shaft swing mechanism 9 is provided with a grasping claw 7 through the W-axis rotating device 8; the grasping claw 7 is provided with an iron chip cleaning device 25, and the bottom of the grasping claw 7 is provided with a buffer device 26.

[0021] As a preferred solution of the present invention, the grasping claw 7 is set as an electro-permanent magnet suction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com