A kind of up and down pressure refractory hydraulic forming machine and one-time forming method thereof

A refractory material and forming method technology, applied in the field of refractory material technology, can solve the problems of increased workload and process time, low production efficiency, high labor intensity, etc., and achieve the goal of simplifying the length of the production forming process, saving costs, and reducing labor intensity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

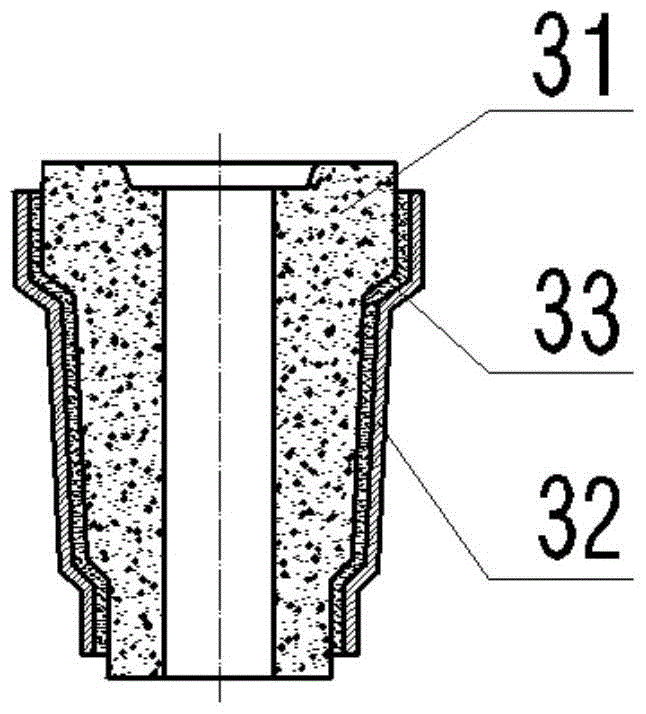

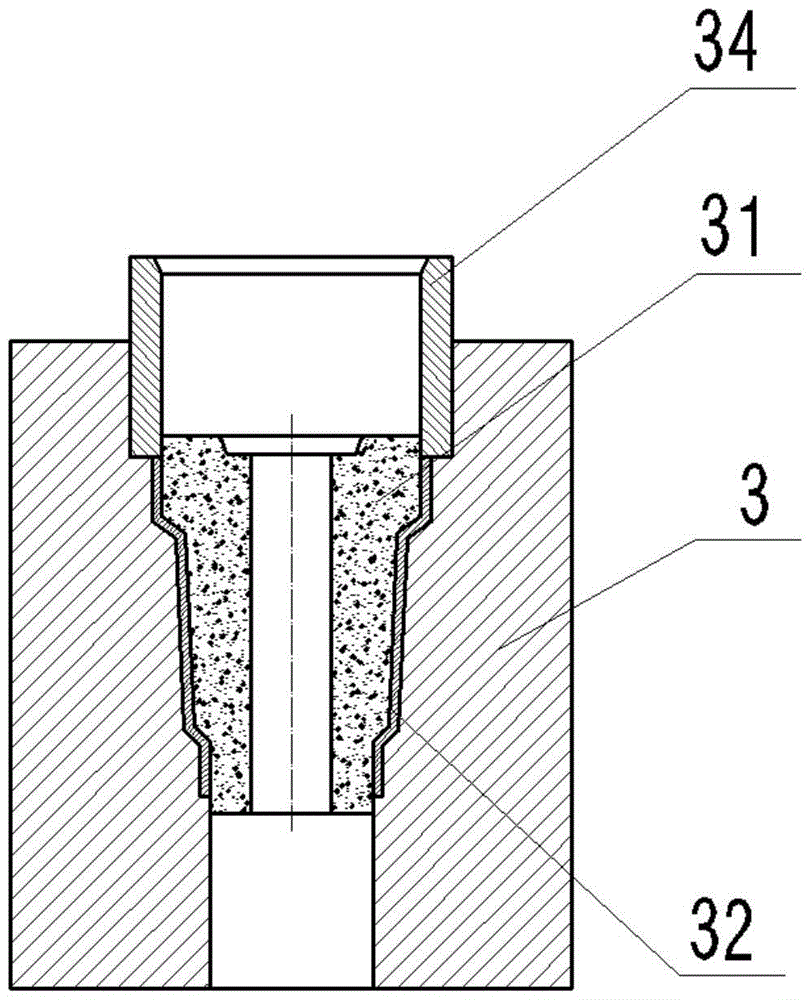

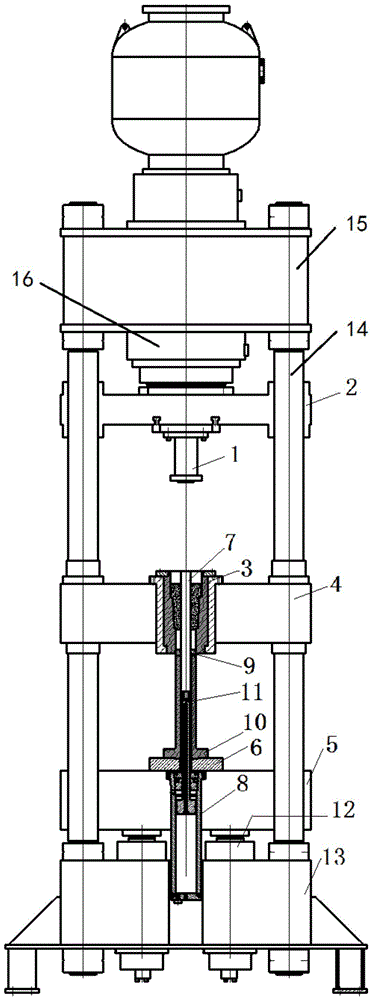

[0025] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

[0026] like image 3 and Figure 4 As shown, the utility model provides a hydraulic forming machine for pressurizing refractory materials up and down, including a base 13, four columns 14 fixedly connected to the four corners of the base, a top beam 15 fixedly connected to the top of the column 14 and a top beam fixedly arranged on the top beam. The upper oil cylinder 16 in the center, the lower oil cylinder 12 is fixedly arranged on the base 13, the upper end of the lower oil cylinder 12 is connected with the lower movable beam 5, and the four corners of the lower movable beam 5 are sleeved on the bottom of the column 14 and can be pushed by the lower oil cylinder 12 Move up and down along the column; the middle p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com