A plastic composite seepage irrigation pipe and its manufacturing method

A composite infiltration and plastic technology, applied in the directions of botanical equipment and methods, tubular articles, other household appliances, etc., can solve the problems of high energy consumption, low production efficiency, easy aging of rubber water swelling, and achieve simple production process, Low production cost and uniform water seepage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

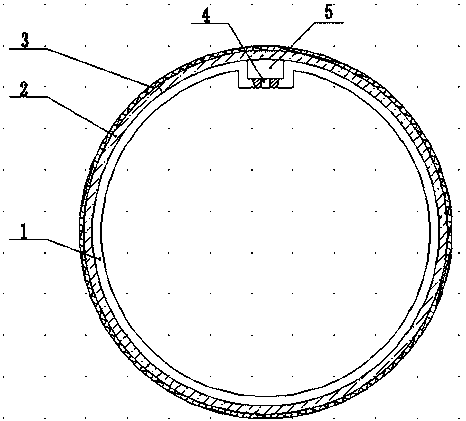

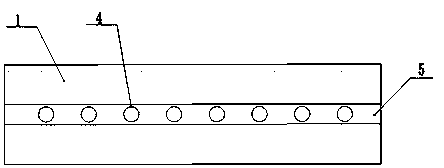

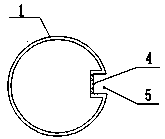

[0021] Such as figure 1 , figure 2 and image 3 As shown, a plastic composite irrigation pipe includes an inner pipe 1, and the inner pipe 1 can be a PE, PP or PVC pipe. The inner tube 1 is provided with a groove 5 , the groove 5 is arranged on the outer surface of the inner tube 1 , and the groove 5 extends along the length direction of the inner tube 1 . The seepage hole 4 is located in the groove 5 . The outer surface of the inner tube 1 is wrapped with a non-woven fabric 2, and the non-woven fabric 2 is made of PET non-woven fabric. The non-woven fabric 2 is provided with a foam material layer 3, and the foam material layer 3 can be PE, PP, PVC or a rubber-plastic mixed foam material layer. The thickness of the foam material layer 3 is 0.2mm-0.5mm. The foam material layer 3 is made of the following components in parts by weight: 15-25 parts of HDPE, 75-85 parts of LLDPE, and 1-2 parts of foaming agent. As a preferred technical solution, the foam material layer is ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com