Lifting handle device mounted on submersible flow pushing device

A submersible flowmaker and short-rod technology, applied in water aeration, transportation and packaging, chemical instruments and methods, etc., can solve problems such as unfavorable work development, center of gravity offset, submersible flowmaker lifting and tilting, etc., to save Effects of processing material resources and processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

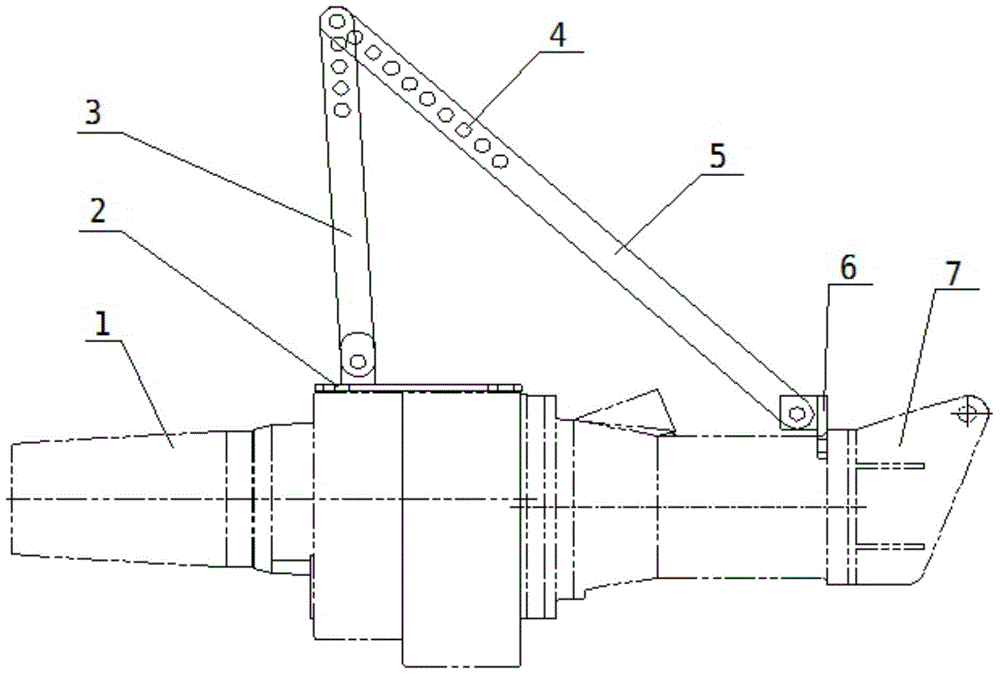

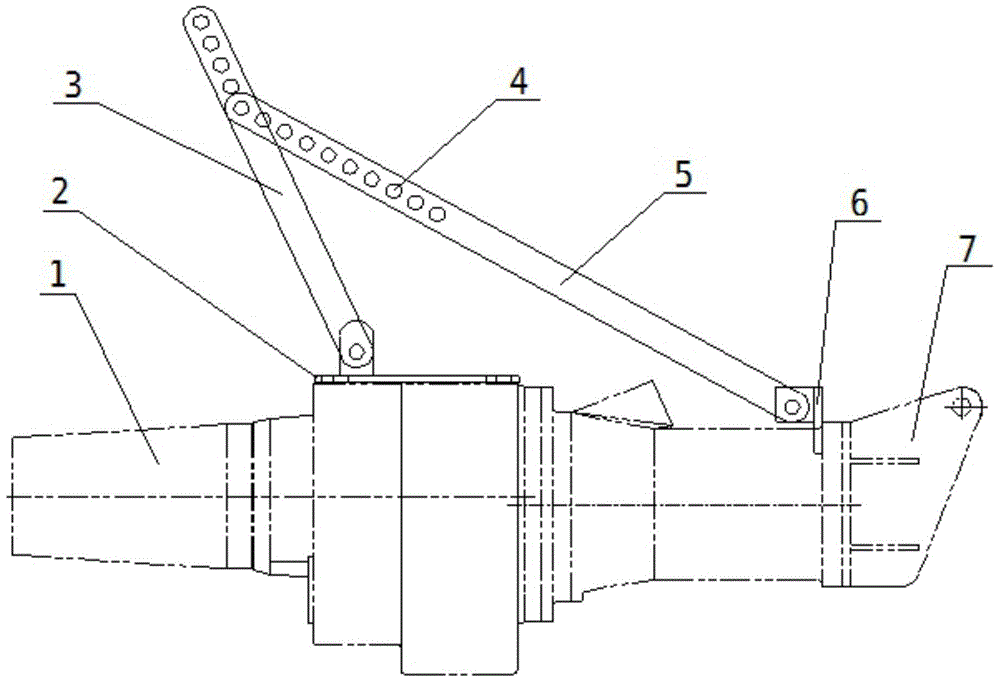

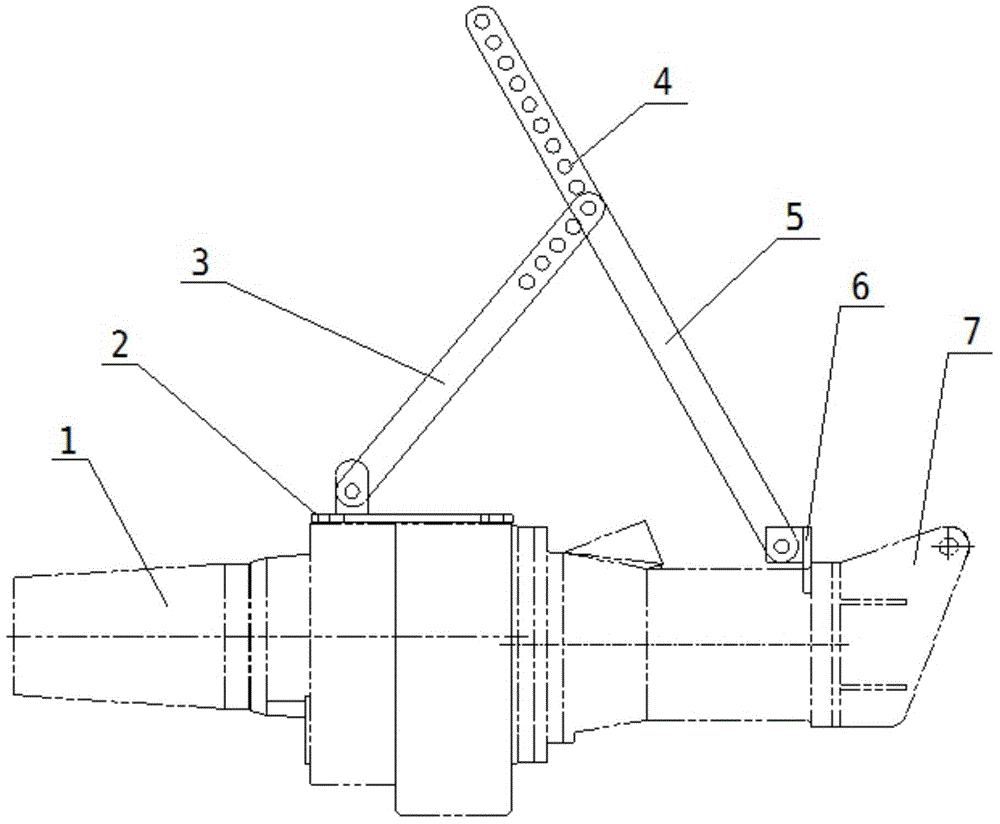

[0015] Such as Figures 1 to 5 As shown, the present invention is a handle device installed on a submersible flow booster, including a host connecting plate 2, a handle short rod 3, a handle long rod 5 and a sliding sleeve connecting plate 6, and one end of the handle short rod 3 There are five hinged holes 4, one end of the long handle 5 is provided with ten hinged holes 4, the short handle 3 and the long handle 5 are not provided with hinged holes 4, and one end of the handle is connected with the host connecting plate 2 and the sliding sleeve respectively. Plate 6 is hinged.

[0016] When the present invention is in use, the host connecting plate 2 is fixed at the middle front part of the host 1 by fasteners, and the sliding sleeve connecting plate 6 is fixed behind the host 1 with fasteners, that is, the connection between the host 1 and the sliding sleeve 7 place. Then match the hinged holes 4 on the short handle 3 with the long handle 5 one by one until the lifting cen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com