Installation and construction process for 1000-ton hoisting and transporting frame equipment

A construction technology and equipment technology, applied in the direction of hoisting equipment braking devices, transportation and packaging, hoisting devices, etc., can solve the problems of large cumulative installation errors of steel structures, side bending of main girder tracks and difficult control of center distance, etc., to achieve Reduce installation workload, avoid mutual influence caused by cross-construction, and improve installation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

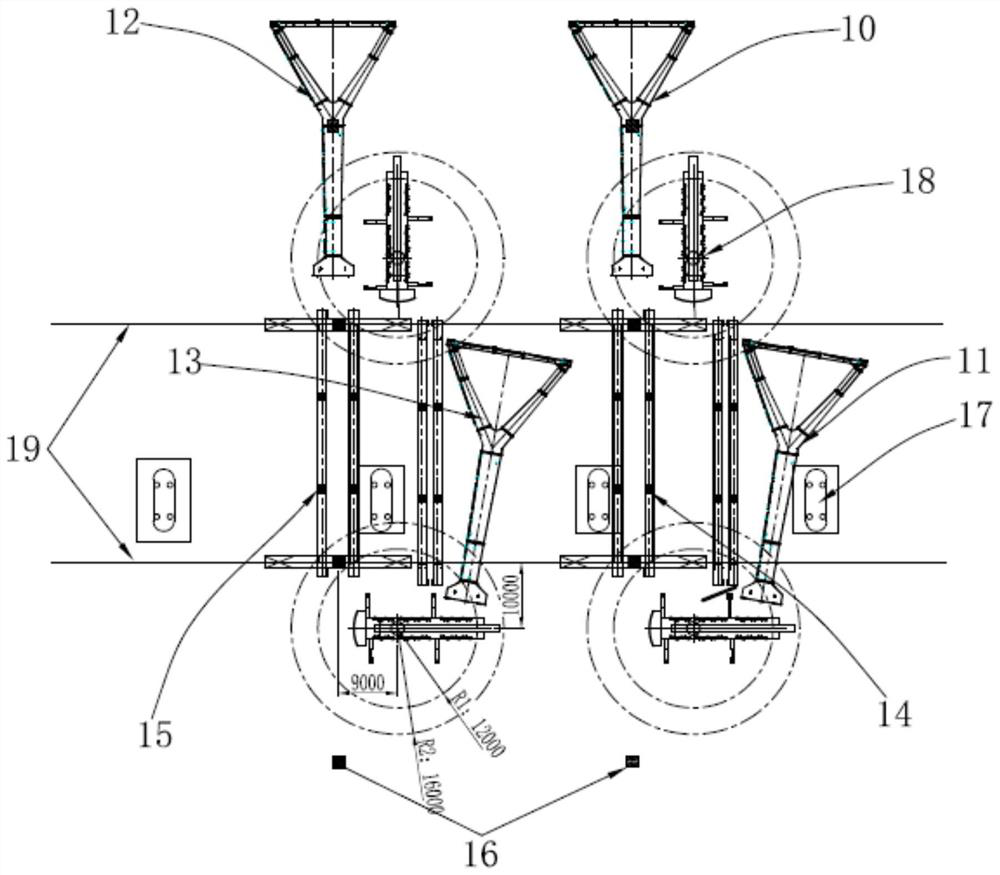

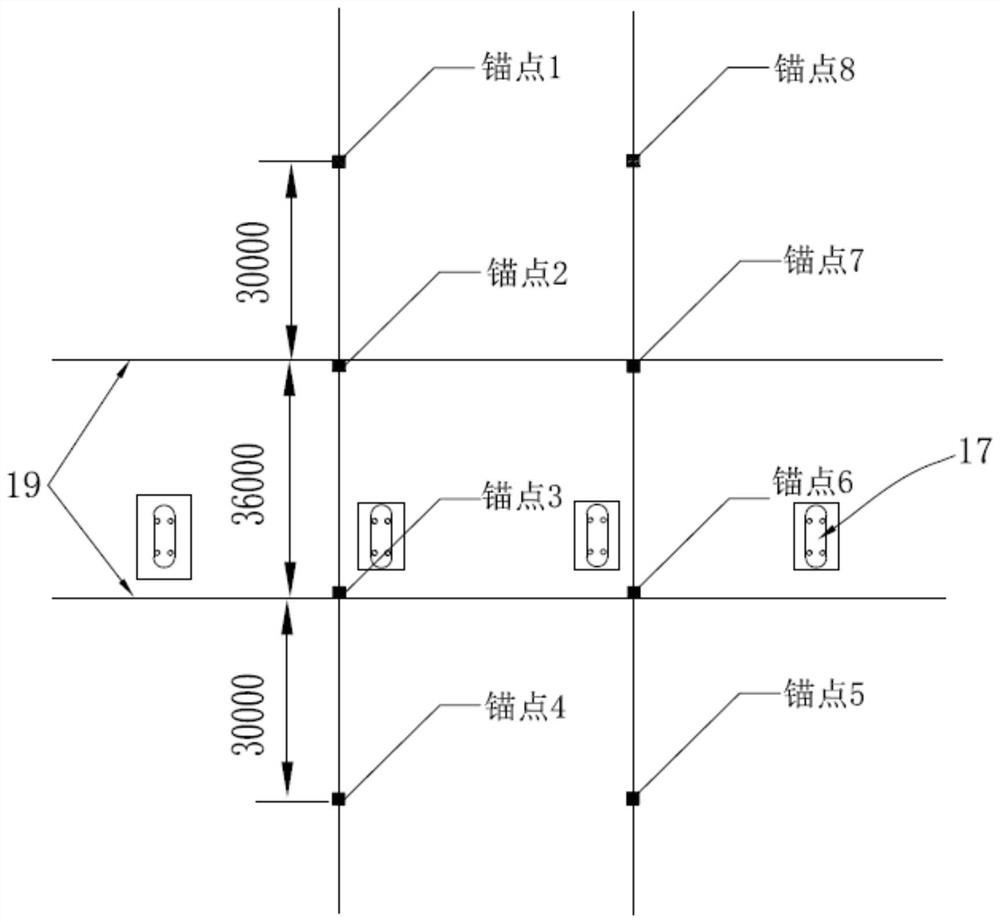

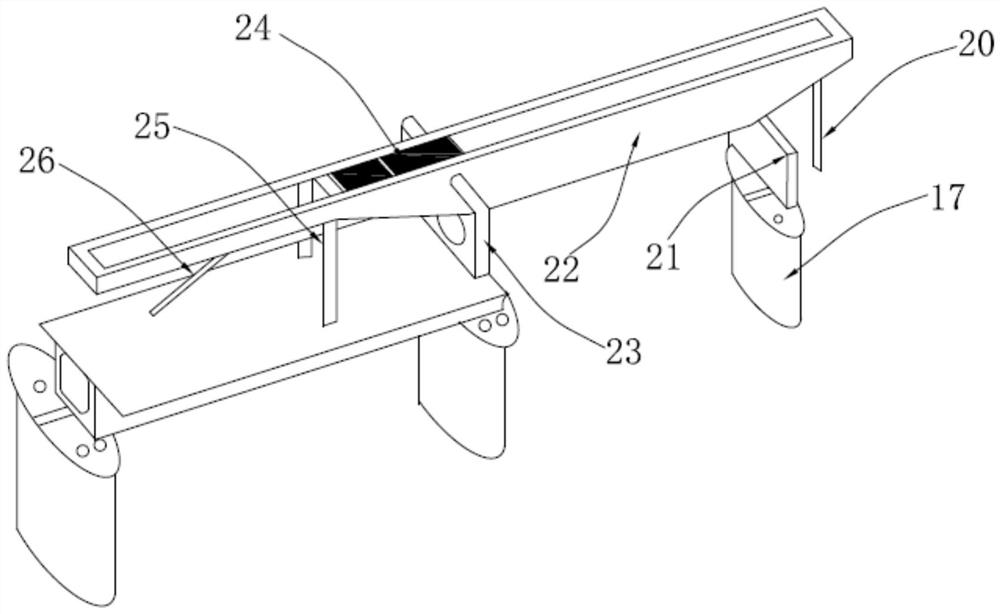

[0028] The 1,000-ton lifting frame equipment is a large-scale special equipment that is transported to the construction site for assembly, inspection and acceptance after each component is produced by the manufacturer, and then put into use. Lifting frame equipment is composed of support system, walking system, power system, hydraulic system, electrical system and safety monitoring system. During the construction process, the 1,000-ton lifting frame equipment has high lifting height, heavy lifting weight, segmented installation and overall hoisting, and fast construction progress. It can be applied to special construction conditions in the beam lifting area with limited space and pier heights exceeding 30 meters.

[0029] The following is an example of a 1000-ton separate lifting frame composed of TLJ500-36 beam lifting machine, YLS1000 beam transporting vehicle and JQS1000 bridge erecting machine.

[0030] There are two TLJ500-36 beam lifting machines in the whole set of equi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com