A pulse type flat membrane bioreactor flushing device and flushing method thereof

A bioreactor and flushing device technology, applied in chemical instruments and methods, sustainable biological treatment, biological water/sewage treatment, etc., can solve the problems of damaged membrane, high energy consumption, low efficiency, etc. Periodic, thorough cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

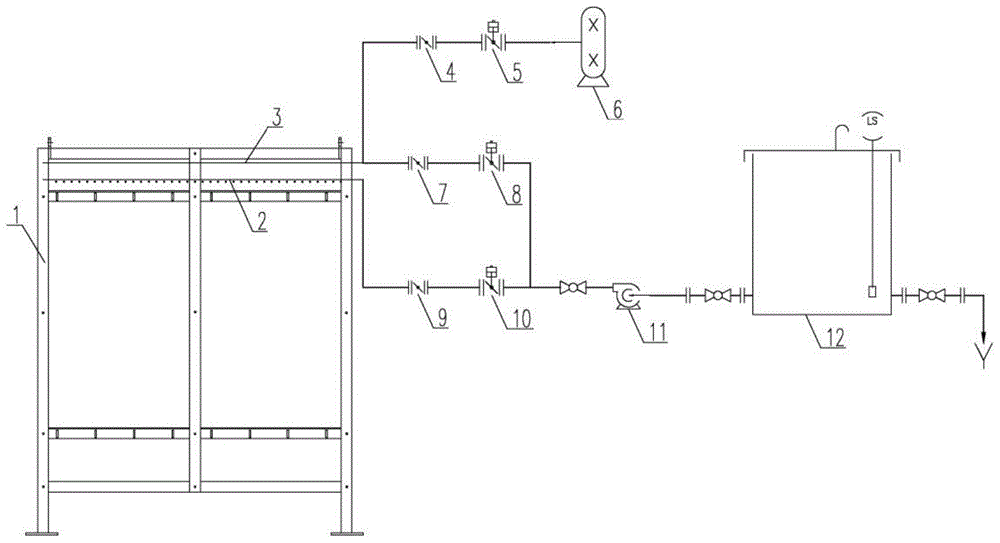

[0035] As shown in the figure, the pulsed flat membrane bioreactor flushing device includes the flat membrane bioreactor body, water distribution pipe, blower, backwashing water tank, water pump, first solenoid valve, second solenoid valve, third solenoid, and second solenoid valve. One check valve, second check valve and third check valve;

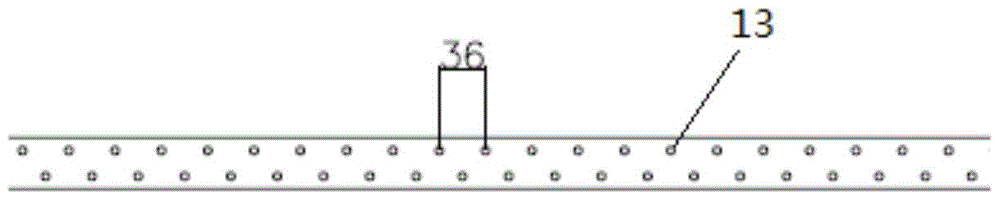

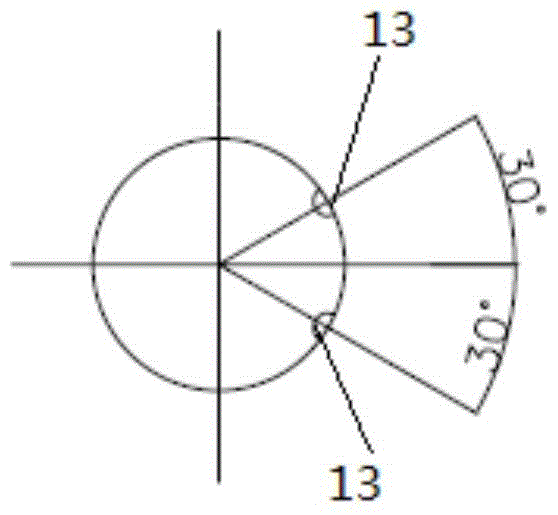

[0036] The flat membrane bioreactor body includes a flat membrane and a flat membrane water production tube. The top of the flat membrane is provided with a water outlet. The wall of the flat membrane water production tube is provided with a water inlet corresponding to the water outlet. The water outlet and the water inlet pass through soft The pipes are connected, and the flat membrane water production pipe is provided with a water outlet; there are 75 flat membranes, and the distance between two adjacent flat membranes is 18mm.

[0037] The water outlet on the flat membrane water pipe is divided into two branches, one is connected to the fi...

Embodiment 2

[0046] It is basically the same as Example 1, but the difference is: the gas used for gas reverse flushing is water vapor; the flat membrane bioreactor is shut down intermittently, specifically, it is turned on for nine minutes and stopped for one minute. Self-flushing the flat membrane bioreactor. In the alternating pulse mode, the time of a single flush of liquid reverse flushing is 2.5min and the pressure is 0.2MPa, and the time of single flush of air reverse flushing is 1.5min, and the pressure is 0.3Mpa.

[0047] The flushing device of the above embodiments does not need to be flushed offline, nor does it need to use any chemical reagents, avoiding the phenomenon of gas phase cutting liquid phase and the phenomenon of gas or liquid phase passing along an uncontaminated unobstructed flow channel, and achieving a thorough cleaning of the inner surface ; Extend the chemical cleaning cycle to 6 months for once, and extend the regeneration repair cycle to more than 8 years.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com