A kind of tobacco seedling raising substrate and preparation method thereof

A seedling raising substrate and tobacco technology, applied in the direction of fertilizer mixture, fertilization device, application, etc., can solve the problem of high cost, achieve the effect of improving utilization rate, loose soil quality, and protecting the natural environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

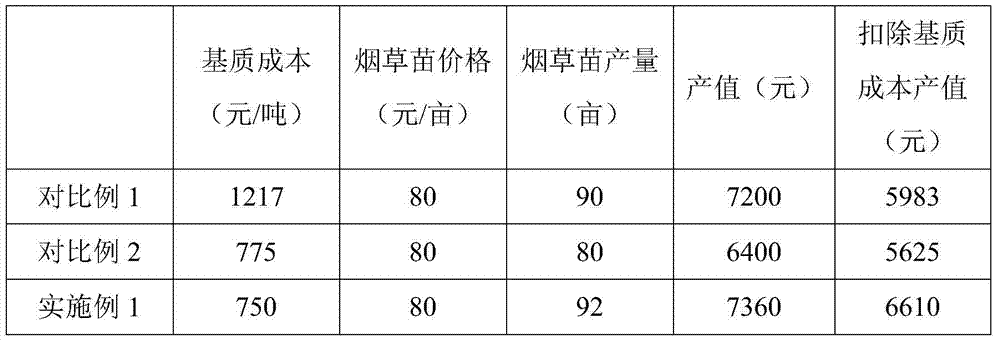

Embodiment 1

[0044] The tobacco seedling substrate is composed of the following materials: decomposed corn cob hydrolyzed residue, sand, horse manure, vermiculite, and papermaking black liquor alkali lignin fertilizer. The mass ratio of the decomposed corncob hydrolyzed residue, horse manure, vermiculite, and papermaking black liquor soda lignin fertilizer in the substrate is 3.5:1.5:1.5:1.2:0.8, and the raw materials are mixed uniformly.

[0045] The preparation method of the tobacco seedling raising substrate is as follows:

[0046] (1) Add a starter equivalent to 2% of the total weight of the raw materials into the corncob hydrolysis residue and mix well, and then ferment for about 15 days in a closed fermentor to obtain the decomposed corncob hydrolysis residue.

[0047] (2) Papermaking black liquor, add dropwise 10% hydrochloric acid solution to pH=2 under stirring conditions; after centrifugal separation, pour out the supernatant, and dry the remaining solids to obtain papermaking black liq...

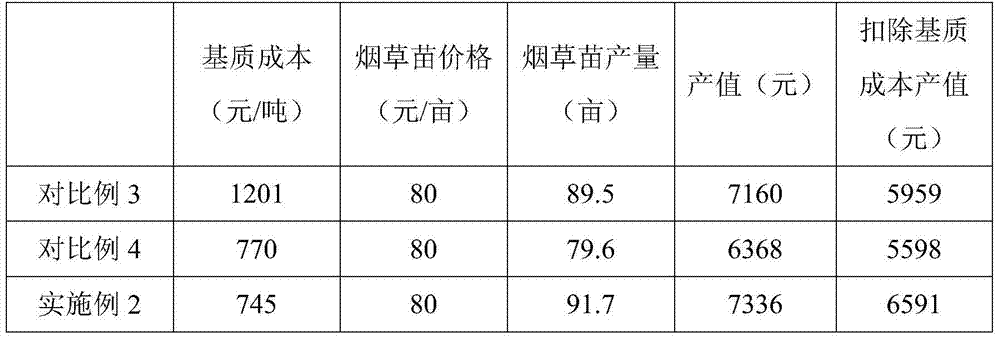

Embodiment 2

[0066] The tobacco seedling substrate is composed of the following materials: decomposed corn cob hydrolyzed residue, sand, chicken manure, vermiculite, papermaking black liquor alkali lignin fertilizer. The mass ratio of the decomposed corncob hydrolyzed residue, horse manure, vermiculite, and papermaking black liquor soda lignin fertilizer in the matrix is 3:1:1.5:1:0.5, and the raw materials are mixed uniformly.

[0067] The preparation method of the tobacco seedling raising substrate is as follows:

[0068] (1) Add a starter equivalent to 2% of the total weight of the raw materials into the corncob hydrolysis residue and mix well, and then ferment for about 15 days in a closed fermentor to obtain the decomposed corncob hydrolysis residue.

[0069] (2) Papermaking black liquor, add dropwise 10% hydrochloric acid solution to pH=2 under stirring conditions; after centrifugal separation, pour out the supernatant, and dry the remaining solids to obtain papermaking black liquor alkal...

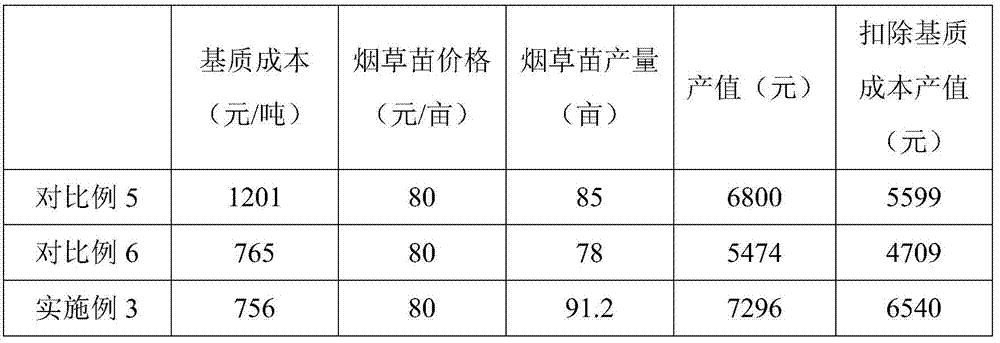

Embodiment 3

[0088] The tobacco seedling substrate is composed of the following materials: decomposed corn cob hydrolyzed residue, sand, horse manure, vermiculite, and papermaking black liquor alkali lignin fertilizer. The mass ratio of the decomposed corncob hydrolyzed residue, horse manure, vermiculite, and papermaking black liquor soda lignin fertilizer in the substrate is 4:2:2:1.5:1, and the raw materials are mixed uniformly.

[0089] The preparation method of the tobacco seedling raising substrate is as follows:

[0090] (1) Add a starter equivalent to 2% of the total weight of the raw materials into the corncob hydrolysis residue and mix well, and then ferment for about 15 days in a closed fermentor to obtain the decomposed corncob hydrolysis residue.

[0091] (2) Papermaking black liquor, add dropwise 10% hydrochloric acid solution to pH=2 under stirring conditions; after centrifugal separation, pour out the supernatant, and dry the remaining solids to obtain papermaking black liquor alka...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com