A kind of preparation method for the modified hyperbranched polyester of environment-friendly dust suppressant

A technology of hyperbranched polyester and modification, applied in the field of chemical dust suppression of pavement, can solve the problems of long time-consuming and low efficiency of the synthesis process, and achieve the effect of shortening the time-consuming of the synthesis process, strong flexibility, and not easy to be crushed and damaged.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

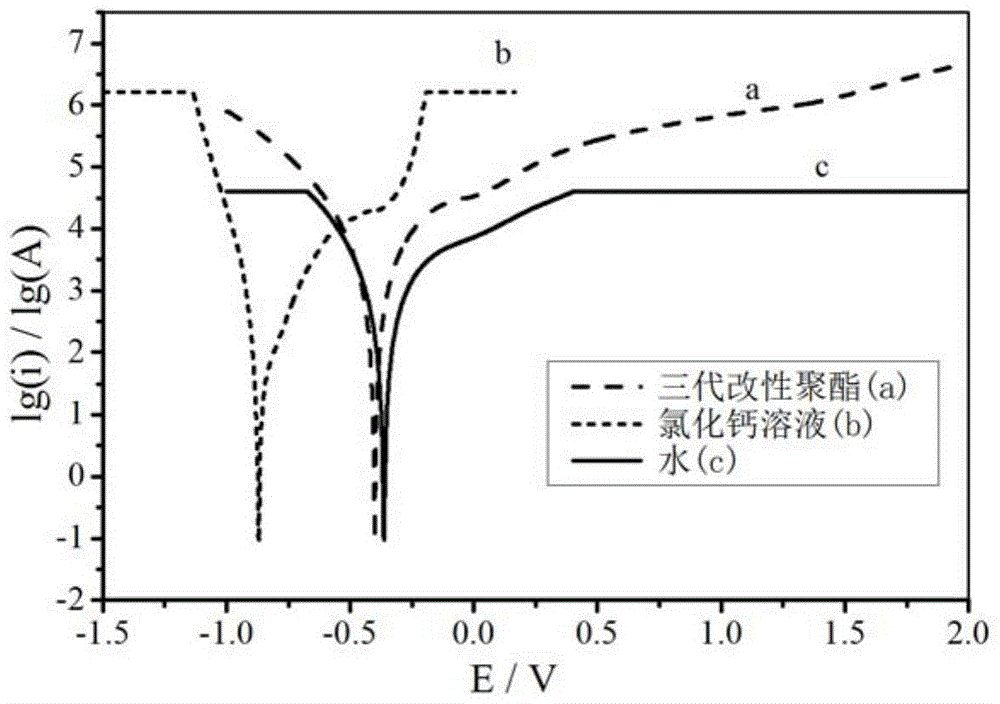

Image

Examples

Embodiment 1

[0026] a monomer N, the preparation of N-dihydroxyethyl-3-aminopropionic acid methyl ester

[0027] Add 1 mole part of methanol into the reactor, slowly add 1 mole part of diethanolamine (DEA) under stirring, continue to stir for 15 minutes, slowly add 1.05 mole part of methyl acrylate (MA) dropwise, and heat up to 40°C for 4 hours after the addition is complete. , and then evacuated to obtain a colorless transparent oil, namely N, N-dihydroxyethyl-3-aminopropionic acid methyl ester.

[0028] Preparation of b second generation hyperbranched polyester

[0029] Add 1 mole part of pentaerythritol and 0.04 mole part of catalyst p-toluenesulfonic acid into the reactor, raise the temperature to 140°C, start stirring, and add dropwise 4 mole parts of N, N-dihydroxyethyl-3-aminopropionic acid methyl ester , N 2 After the protection reaction for 3 hours, vacuumize for 1 hour; add 8 molar parts of N, N-dihydroxyethyl-3-aminopropionic acid methyl ester and 0.08 molar parts of catalyst ...

Embodiment 2

[0035] Monomer N, the preparation method of N-dihydroxyethyl-3-aminopropionic acid methyl ester and second generation hyperbranched polyester is the same as embodiment 1, and difference is:

[0036] a preparation of modified monomer

[0037] Add 1 mole part of stearic acid and 0.01 mole part of catalyst p-toluenesulfonic acid into the reactor, start stirring, raise the temperature to 100°C, start stirring, and dropwise add 1 mole part of N,N-dihydroxyethyl-3- Methyl amine propionate, N 2 After the protection reaction for 3 hours, vacuumize for 1 hour to obtain a dark brown solid, which is the modified monomer.

[0038] Preparation of b modified hyperbranched polyester

[0039]In the reactor, add 1 mole part of the second generation hyperbranched polyester, 14 mole parts of monomer N, N-dihydroxyethyl-3-amine propionate methyl ester and 2 mole parts of modified monomer, and 0.2 mole part of catalyst p-toluenesulfonic acid, N 2 Under protection, magnetic or mechanical stirri...

Embodiment 3

[0041] Monomer N, the preparation method of N-dihydroxyethyl-3-aminopropionic acid methyl ester and second generation hyperbranched polyester is the same as embodiment 1, and difference is:

[0042] a preparation of modified monomer

[0043] Add 1 mole part of stearic acid and 0.06 mole part of catalyst p-toluenesulfonic acid into the reactor, raise the temperature to 140°C, start stirring, and dropwise add 1 mole part of N,N-dihydroxyethyl-3-aminopropionic acid Methyl ester, N 2 After 1.5 h of protection reaction, vacuum was applied for 1 h to obtain a dark brown solid, namely the modified monomer.

[0044] Preparation of b modified hyperbranched polyester

[0045] Add 1 mole part of second-generation hyperbranched polyester, 10 mole parts of monomer N, N-dihydroxyethyl-3-amine propionate methyl ester and 6 mole parts of modified monomer, and 0.005 mole part of catalyst in the reactor p-toluenesulfonic acid, N 2 Under protection, magnetic or mechanical stirring, react at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com