Preparation method of chopped carbon fiber interlayer reinforced fiber composite material

A fiber composite material and chopped carbon fiber technology, applied in the field of materials, can solve the problems of complex process and high cost of recycling carbon fiber composite materials, and achieve the effect of simple process, improved mechanical properties and easy molding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

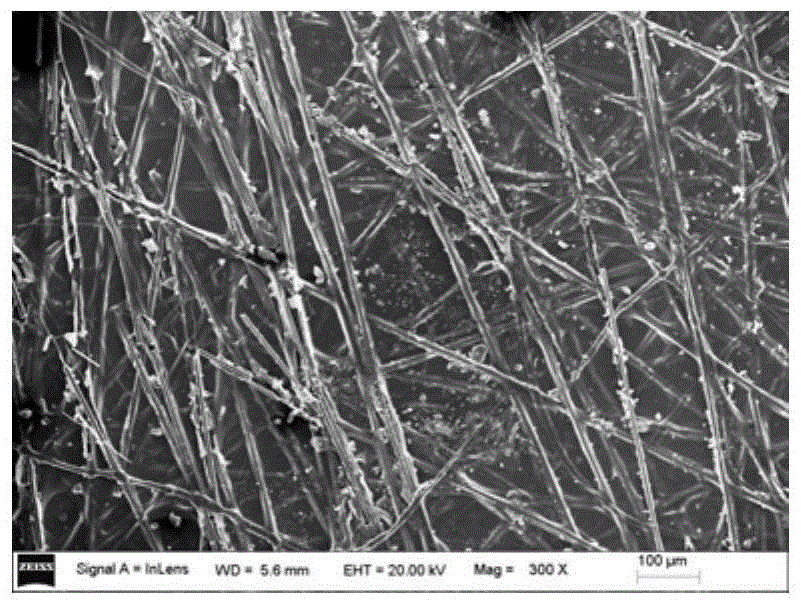

Image

Examples

Embodiment 1

[0016] Chopped carbon fibers, cellulose nanofibers, deionized water, bisphenol A water-based epoxy resin with CF:NFC:H 2 O:WEP=2:1:200:20 mass ratio is put into the device for mechanical stirring, with a speed of 1000r / min, react for 15min to obtain a dispersed aqueous solution of chopped carbon fiber; pour the aqueous solution of chopped carbon fiber into the mold , and then dried in a blast oven at 100°C to obtain an interlayer reinforced and toughened chopped carbon fiber film; the interlayer reinforced and toughened chopped carbon fiber film is placed in a layer of natural jute fiber cloth, which can be placed 1 layer of interlayer reinforced and toughened chopped carbon fiber film, and then resin transfer molding method, using epoxy resin + amine curing agent system for prepreg, to obtain prepreg fiber cloth; the obtained prepreg fiber cloth is used The method of compression molding is cured and formed according to the selected epoxy resin + amine curing agent system, and...

Embodiment 2

[0018] Chopped carbon fibers, cellulose nanofibers, deionized water, bisphenol A water-based epoxy resin with CF:NFC:H 2 O:WEP=0.1:1:200:0 mass ratio is put into the device for mechanical stirring, at a speed of 800r / min, react for 10min to obtain a dispersed aqueous solution of chopped carbon fiber; pour the aqueous solution of chopped carbon fiber into the mold , and then dried in a blast oven at 80°C to obtain an interlayer reinforced and toughened chopped carbon fiber film; the interlayer reinforced and toughened chopped carbon fiber film is placed in a layer of natural jute fiber cloth, which can be placed 1 layer of interlayer reinforced and toughened chopped carbon fiber film, and then resin transfer molding method, using epoxy resin + amine curing agent system for prepreg, to obtain prepreg fiber cloth; the obtained prepreg fiber cloth is used The method of compression molding is cured and formed according to the selected epoxy resin + amine curing agent system, and th...

Embodiment 3

[0020] Chopped carbon fibers, cellulose nanofibers, deionized water, bisphenol A water-based epoxy resin with CF:NFC:H 2 O: WEP = 3:1:200:30 mass ratio into the device for mechanical stirring, at a speed of 1500r / min, react for 30min to obtain a dispersed aqueous solution of chopped carbon fiber; pour the aqueous solution of chopped carbon fiber into the mold , and then dried in a blast oven at 100°C to obtain an interlayer reinforced and toughened chopped carbon fiber film; the interlayer reinforced and toughened chopped carbon fiber film is placed in a layer of natural jute fiber cloth, which can be placed 1 layer of interlayer reinforced and toughened chopped carbon fiber film, and then resin transfer molding method, using epoxy resin + amine curing agent system for prepreg, to obtain prepreg fiber cloth; the obtained prepreg fiber cloth is used The method of compression molding is cured and formed according to the selected epoxy resin + amine curing agent system, and the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com