Alkali-resistant fast-dyeing disperse dye and preparation method thereof

A rapid dyeing and disperse dye technology, applied in the field of dyes, can solve the problems of insufficient dyeing speed, high cost, weak alkali resistance of fabrics, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

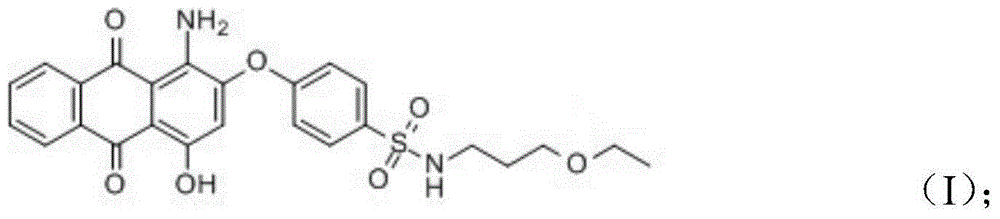

[0025] Alkali-resistant fast dyeing disperse dyes, respectively mix the following components, component A: 40%, component B: 20%, component C: 15%, component D: 1%, dispersant 24%. Composition of red color dye composition. Described component A, its structural formula (I) is as follows:

[0026]

[0027] Described component B, its structural formula (II) is as follows:

[0028]

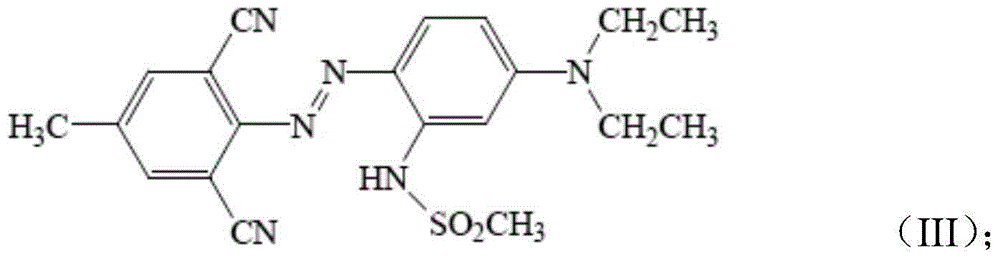

[0029] Described component C, its structural formula (III) is as follows:

[0030]

[0031] Described component D, its structural formula (IV) is as follows:

[0032] According to the above-mentioned component distribution ratio, each component is weighed for proportioning, pulverized and granulated. In this step, sand is used as the grinding medium for grinding, and the sand is ground and filtered. Spray drying or drying in an oven. Drying in an oven includes pre-drying at 70°C±5°C for 5-6 minutes, and then baking at 90°C±5°C for 9-10 minutes. Add a dispersant and stir in the blending ...

Embodiment 2

[0034] Alkali-resistant fast dyeing disperse dyes, respectively mix the following components, component A: 60%, component B: 20%, component C: 15%, component D: 1%, dispersant 4%. Composition of red color dye composition. The molecular formula is as shown in Example 1. According to the above-mentioned component distribution ratio, each component is weighed for proportioning, pulverized and granulated. In this step, sand is used as the grinding medium for grinding, and the sand is ground and filtered. Spray drying or drying in an oven. Drying in an oven includes pre-drying at 70°C±5°C for 5-6 minutes, and then baking at 90°C±5°C for 9-10 minutes. Add a dispersant and stir in the blending equipment for 1-2 hours until the diffusion level reaches 3-4. Dry blending is carried out at a temperature lower than 30°C, and the finished product is obtained after mixing evenly. When using, take 1 gram of the finished product, disperse it in 200 grams of cold water, mix it with 90 mL of ...

Embodiment 3

[0036] Alkali-resistant fast dyeing disperse dyes, respectively mix the following components, component A: 50%, component B: 30%, component C: 15%, component D: 1%, dispersant 4%. Composition of red color dye composition. The molecular formula is as shown in Example 1. According to the above-mentioned component distribution ratio, each component is weighed for proportioning, pulverized and granulated. In this step, sand is used as the grinding medium for grinding, and the sand is ground and filtered. Spray drying or drying in an oven. Drying in an oven includes pre-drying at 70°C±5°C for 5-6 minutes, and then baking at 90°C±5°C for 9-10 minutes. Add a dispersant and stir in the blending equipment for 1-2 hours until the diffusion level reaches 3-4. Dry blending is carried out at a temperature lower than 30°C, and the finished product is obtained after mixing evenly. When using, take 1 gram of the finished product, disperse it in 200 grams of cold water, mix it with 90 mL of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com