Titanium alloy with easily refined grains and preparing method thereof

A technology for refining grains and titanium alloys, applied to TiNb-based ultra-fine-grained and nano-crystalline titanium alloys and their preparation, large-scale ultra-fine-grained titanium alloys or nano-crystalline titanium alloys and their preparation, titanium alloys and their preparation, In the field of low stacking fault energy, it can solve the problems of not fine enough grains, not large enough material size, and not dense enough, so as to reduce the difficulty of process control and manufacturing costs, improve production efficiency, and broaden the application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

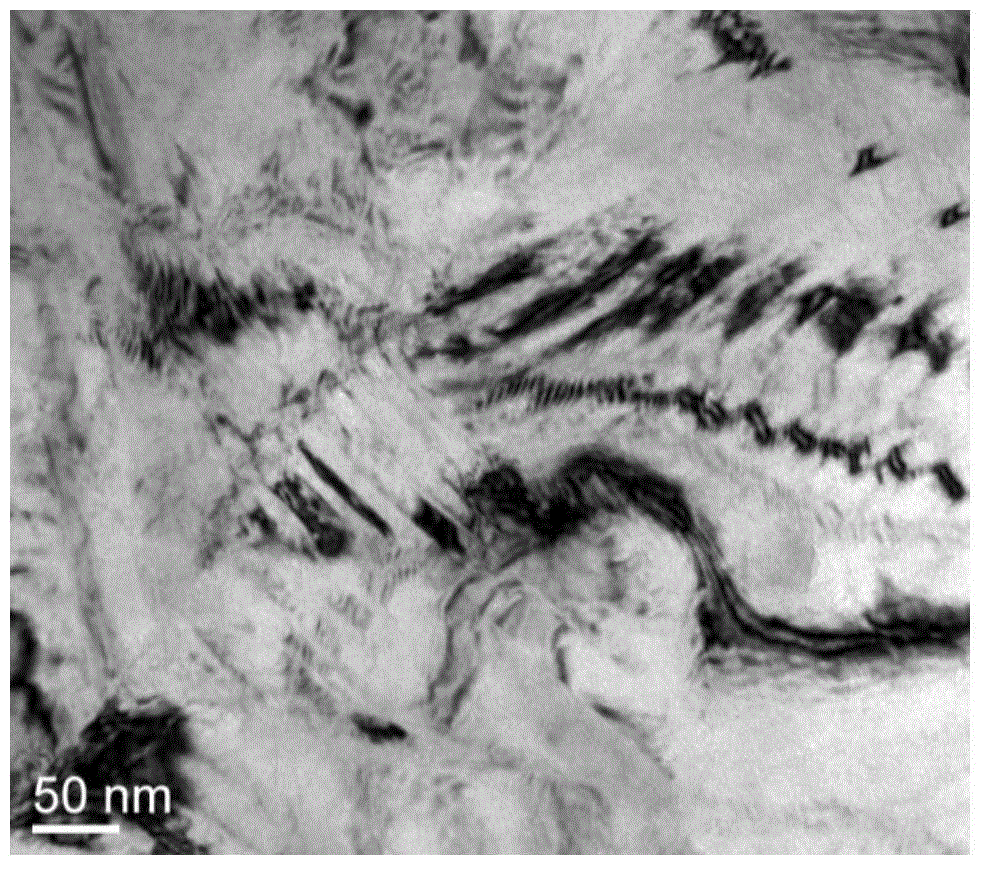

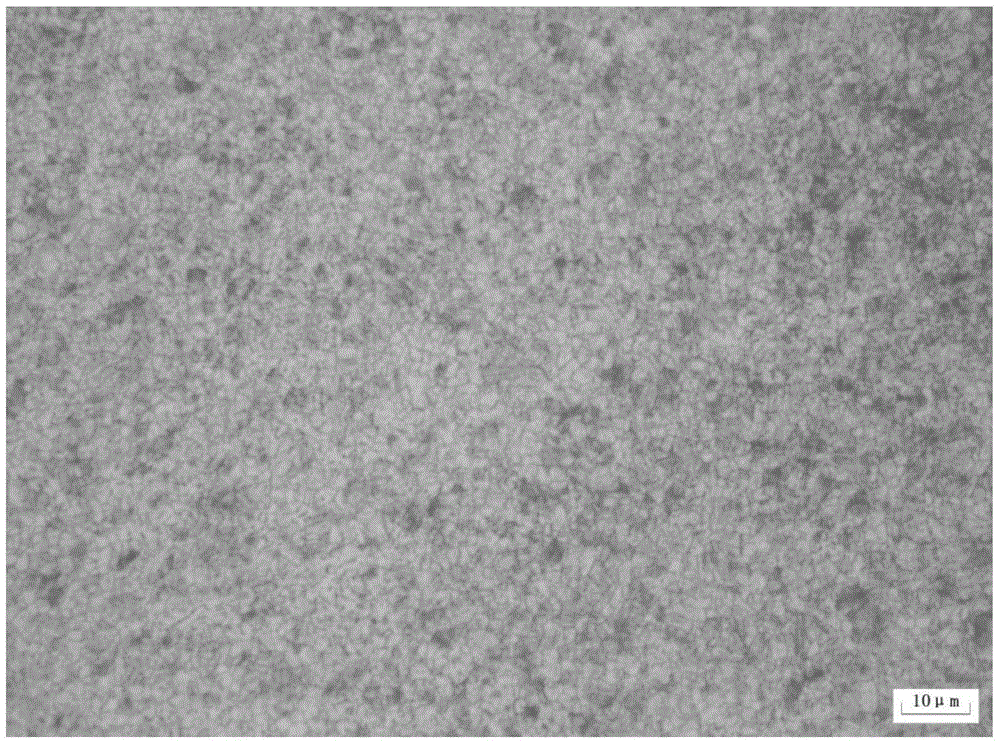

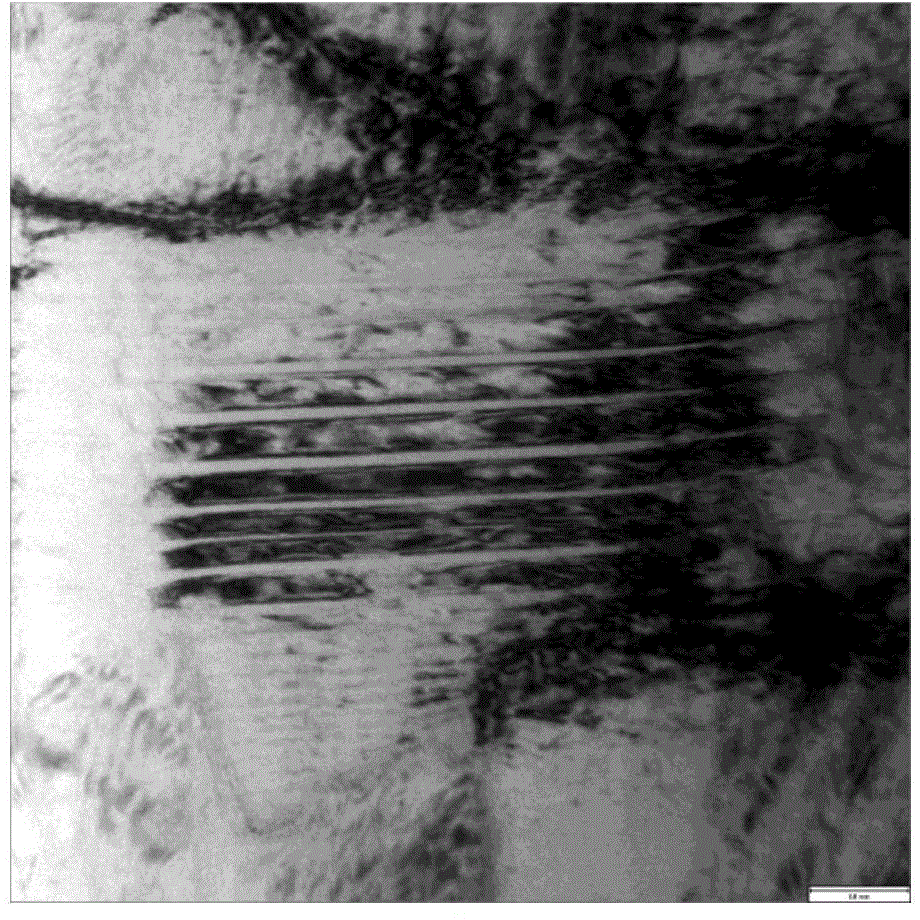

[0067] The preferred solutions of the present invention are described below in conjunction with the accompanying drawings and specific embodiments, but it should be understood that these descriptions are only for further illustrating the features and advantages of the present invention, rather than limiting the claims of the present invention.

[0068] Refer to Table 1 for the nominal composition of the Ti-Nb-O alloys of Examples 1 to 16.

[0069] The alloy is prepared according to the composition (weight percentage, wt%) shown in Table 1, the raw materials are selected, and after batching, the electrode is pressed into an electrode, and the alloy ingot is obtained by smelting in a vacuum consumable electric arc furnace for many times. The ingot is homogenized at 900°C to 1100°C for 20h to 30h to prepare an ingot with uniform chemical composition. Blank forging at 900°C-950°C, and multi-fire forging at 800°C-950°C to refine the structure, and finally forge into a δ40mm slab, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com