Continuous hot dipping sink roll slag deposition device and slag deposition method

A sinking roll and hot-dip coating technology, which is applied in the hot-dipping process, coating, metal material coating process, etc., can solve the problems of serious slag on the surface of the sinking roll and difficulty in completely removing the slag on the online scraper, and achieve shortening The effect of maintenance progress, easy promotion and use, and convenient disassembly and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

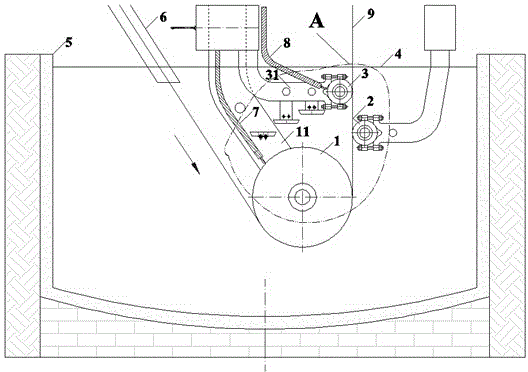

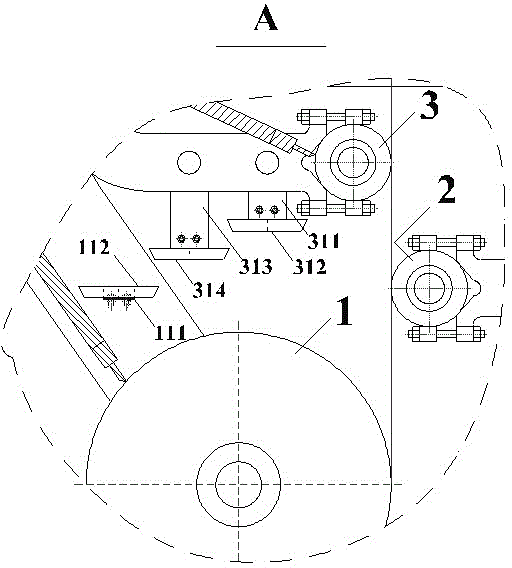

[0025] Example 1 : see figure 1 , figure 2 , a continuous hot-dip plating sinking roll slagging device, the slagging device includes a sinking roll 1, a stabilizing roll, and the stabilizing roll includes an upper stabilizing roll 3 and a lower stabilizing roll 2, and the upper stabilizing roll 3 is fixed on the upper On the stabilizing roller cantilever 31, the sinking roller 1 is fixed on the sinking roller cantilever 11, and the upper stabilizing roller cantilever 31 is provided with multiple sets of slagging pans, and multiple sets of slagging pans form a fence, and the slagging pans are located at Between sinking roll 1 and upper stabilizing roll 3. The multiple sets of slag accumulation trays set up in this technical solution form a fence, which can weaken the strong agitation of the local melt above the sinking roller, which is conducive to the deposition of zinc slag, can significantly reduce or eliminate the slag on the surface of the sinking roller, and improve ...

Embodiment 2

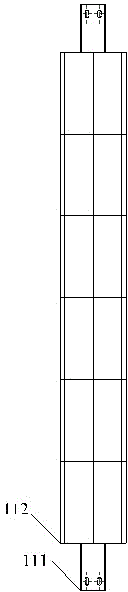

[0026] Example 2 : see figure 1 , figure 2 , as an improvement of the present invention, the multiple sets of slagging pans include an upper slagging pan 312, a middle slagging pan 314 and a bottom slagging pan 112, and the upper slagging pan 312, the middle slagging pan 314 and the bottom The two ends of the slag accumulation pan 112 are respectively provided with an upper slag accumulation pan support 311 , a middle slag accumulation pan support 313 and a bottom slag accumulation pan support 111 . The rest of the structures and advantages are exactly the same as in Embodiment 1.

Embodiment 3

[0027] Example 3 : see figure 1 , as an improvement of the present invention, the slag accumulation device also includes a scraper device, the scraper device includes an upper scraper 8, a lower scraper 7, a transmission mechanism that drives the movement of the scraper, and a drive motor, and the upper scraper 8 is located on the upper stable Above the roller cantilever 31 , the lower scraper 7 is located at the lower part of the sinking roller cantilever 11 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com