Washing machine flocculation device with self-cleaning function and washing machine

A flocculation device, washing machine technology, applied in the direction of washing devices, other washing machines, household appliances, etc., can solve the problems of not having cleaning function, breeding bacteria, etc., and achieve the effect of preventing flocs from breaking up, speeding up mixing, and improving the degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

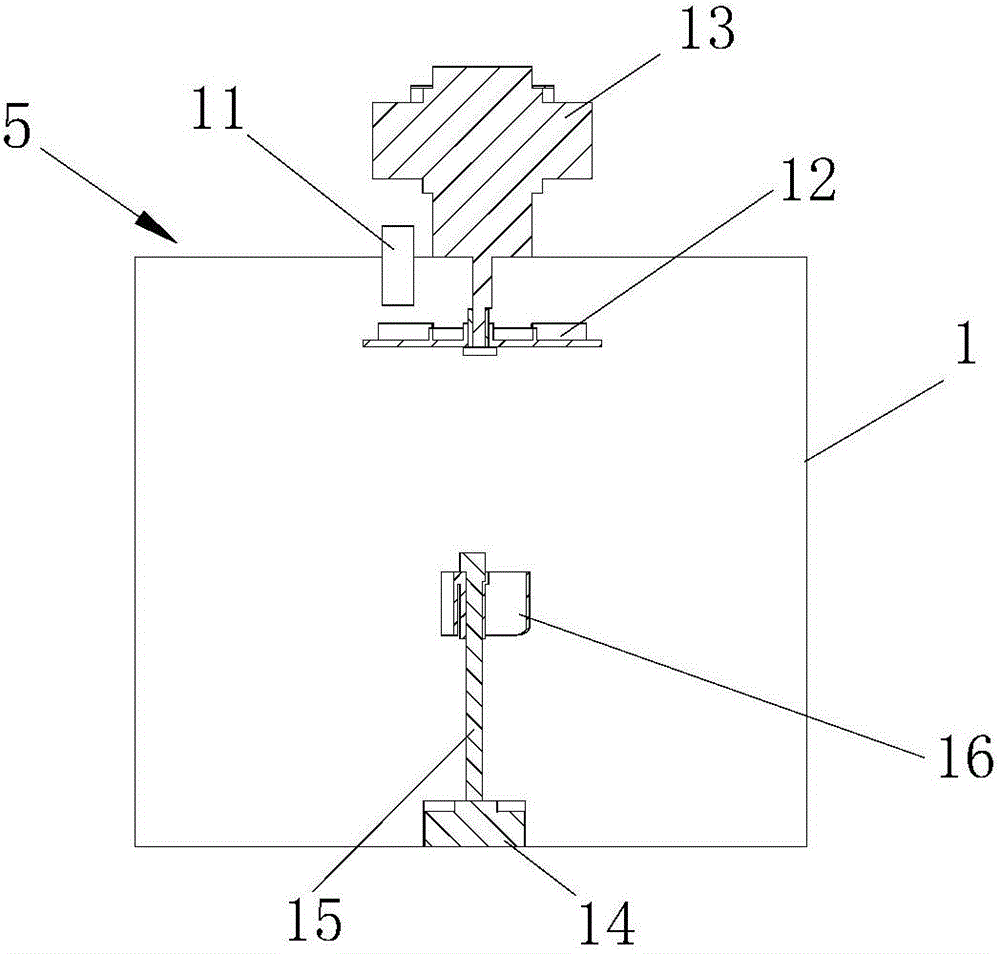

[0041] Such as image 3 As shown, the driving motor 13 described in this embodiment is arranged above the flocculation container, the stirring motor 14 is arranged at the bottom of the flocculation container 1 , and the stirring shaft 15 extends upward to the inside of the flocculation container 1 .

[0042] In addition to the above installation structure, the stirring motor 14 can also be arranged on the side of the flocculation container 1, and the stirring shaft 15 extends from the side to the inside of the flocculation container 1, or the stirring motor 14 and the driving motor 13 are both arranged on the top of the flocculation container (Fig. not shown).

Embodiment 2

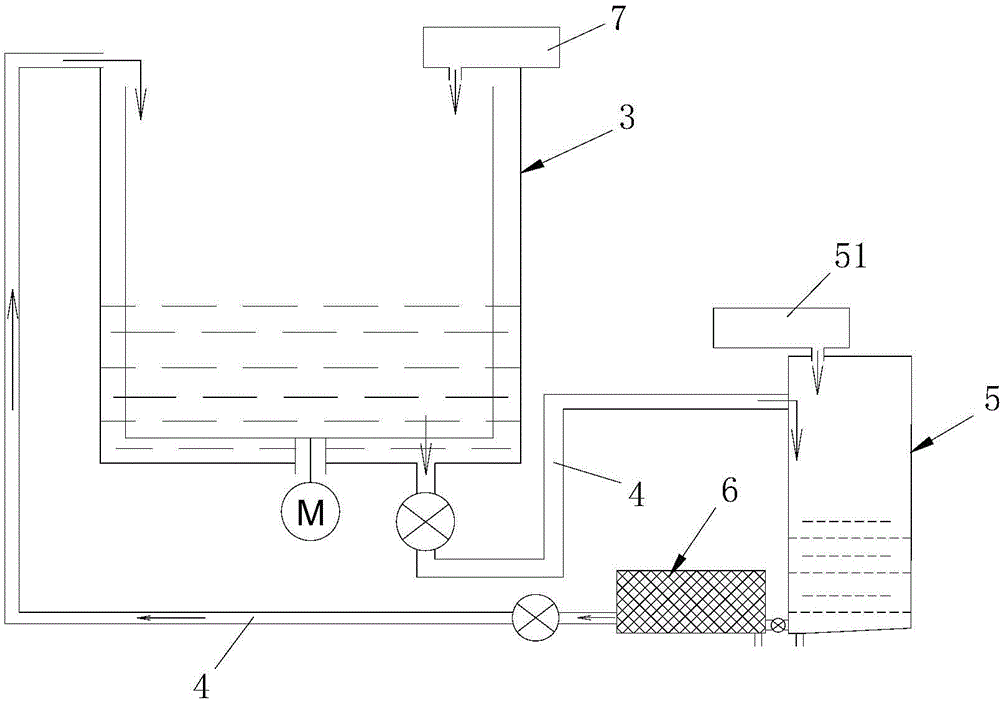

[0044] Such as Figure 4 and Figure 5 As shown, this embodiment is a further improvement made on the basis of Embodiment 1. The driving motor 13 that drives the rotation of the water-spinning impeller 12 is also the aforementioned stirring motor 14, that is, the driving motor 13 and the described stirring motor 14 are With the same motor, the water-repelling impeller 12 is coaxially installed on the stirring shaft 15, the stirring impeller 16 is installed on the bottom end of the stirring shaft 15, and the water-repelling impeller 12 is installed on the stirring shaft 15 near the position of the stirring motor 14. When cleaning the flocculation container 1, the stirring motor 14 drives the impeller to rotate at a high speed. Due to the centrifugal force of the rotating impeller 12, the incoming water is thrown to the inner wall of the flocculation container 1 at a certain speed for cleaning. In order to expand the range of water rejection, the stirring motor is controlled 14...

Embodiment 3

[0048] Such as Figure 5 and Figure 6 As shown, in this embodiment, a water guide groove 17 is provided in the flocculation container 1 to guide the water from the water inlet 11 of the flocculation container to the impeller 12 for throwing water. The gutter 17 structure is not essential, such as image 3 As shown, the water inlet 11 is above the water-spinning impeller 12, and the water enters until on the water-spinning impeller 12.

[0049] Above-mentioned water inlet 11 water inlet cleaning can be the water after washing machine washing, or for washing with clear water, or install a three-way valve, connect tap water and washing machine washing water respectively, enter the water after washing when circulating water, and enter water during washing. Clear water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com