Stepless flow control device

A flow control device, a stepless technology, which is applied to wellbore/well valve devices, production fluids, wellbore/well components, etc., can solve problems such as poor reliability, achieve safe and reliable use, and meet the needs of fine flow control and adjustment. handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

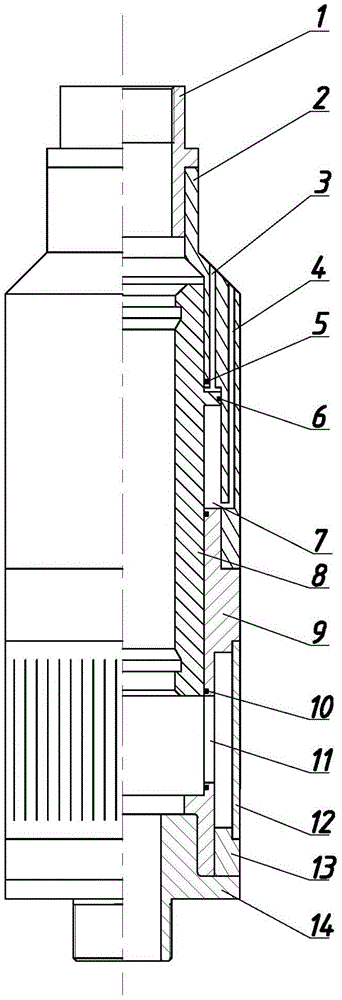

[0022] like Figure 1-3 As shown, the stepless flow control device includes: an upper joint 1, an upper outer sleeve 2, an inner sliding sleeve 8, a lower outer sleeve 9, a slotted screen 12, a screen fixing block 13, and a lower joint 14; wherein, the upper outer sleeve 2, The lower jacket 9 is connected by threads, and the upper jacket 2 and the lower jacket 9 are connected to form an inner cavity, and the inner sliding sleeve 8 is located in the inner cavity; the inner sliding sleeve 8, the upper jacket 2 and the lower jacket 9 form a piston cylinder 7; the upper jacket 2 is provided with an upper hydraulic passage 3 and a lower hydraulic passage 4, and the upper hydraulic passage 3 and the lower hydraulic passage 4 communicate with the upper and lower ends of the piston cylinder 7 respectively; the outer side of the inner sliding sleeve 8 has a cylindrical step 81, and the cylindrical step 81 It forms a gap fit with the wall surface of the piston cylinder 7, and realizes a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com