Energy-saving horizontal direct-connected single-stage double-suction centrifugal pump

A direct-connected single-stage, energy-saving technology, applied in the direction of non-variable pumps, pumps, pump components, etc., can solve the problem of temperature rise of motors and motor bearings, affecting motor performance and production efficiency, and double-suction centrifugal pumps occupying an area Large area and other problems, to achieve the effect of fewer failure points, convenient pump room layout, and convenient pipeline design and layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

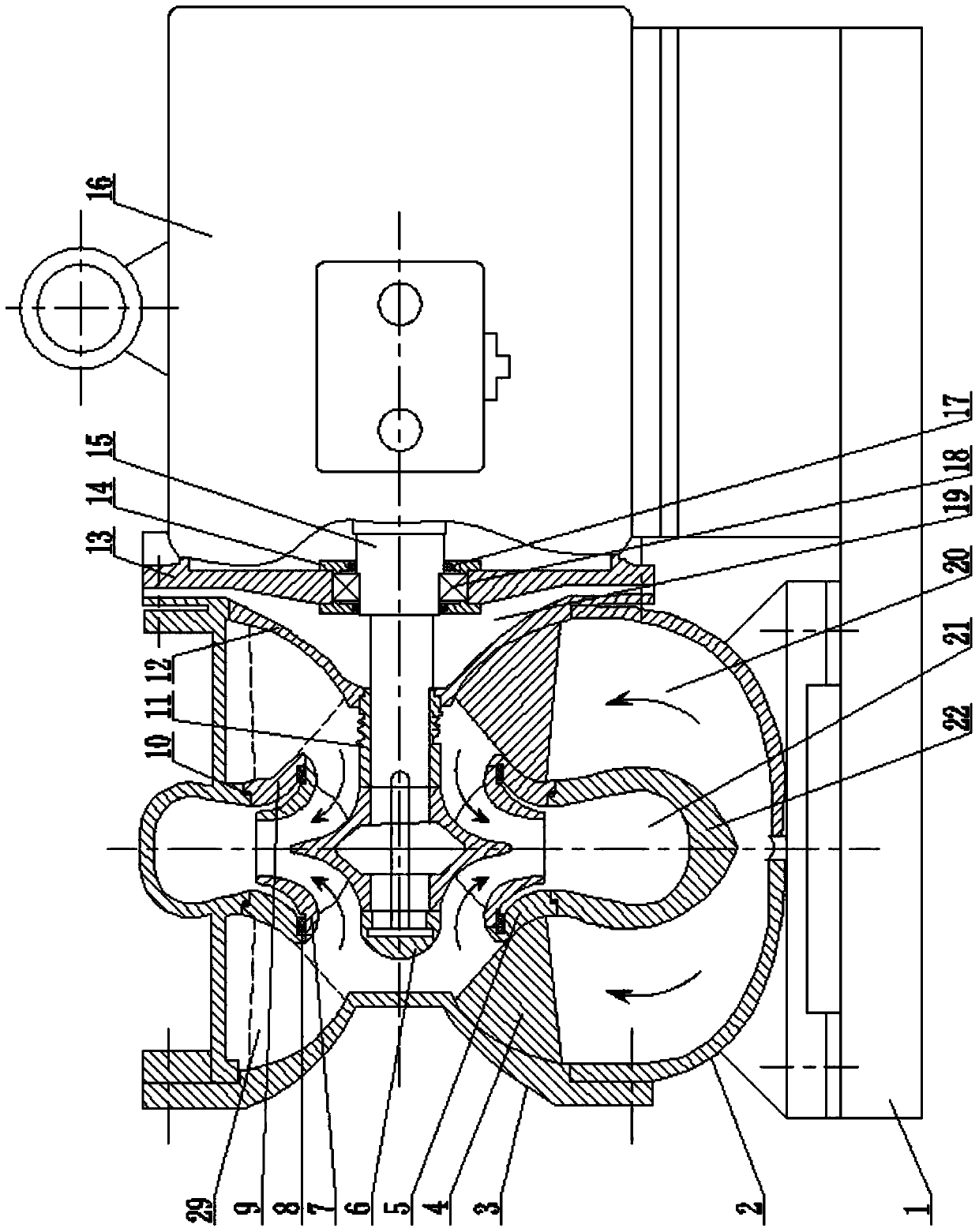

[0030] Such as figure 1 As shown, the energy-saving horizontal direct-connected single-stage double-suction centrifugal pump includes a pump body 2, a pump cover, an impeller 7 and a motor 16. The pump body 2 is provided with a suction vortex chamber 20 on both sides and a middle discharge vortex chamber 21. The pump cover is composed of the pump cover I3 and the pump cover II12 which are arranged on the left and right sides of the pump body 2 respectively. The side cover 13 of the motor 16 is connected and fixed with the pump cover II12 on the corresponding side, and an open air is provided between them. Isolate the gap 19, the motor shaft 15 passes through the pump cover II13 and enters the pump body 2, and the impeller 7 is installed on the motor shaft 15 corresponding to the center position of the middle discharge vortex chamber 21, and a bellows type dynamic valve is provided between the impeller 7 and the pump cover II12. Seal 11, the end of the motor shaft 15 is provid...

Embodiment 2

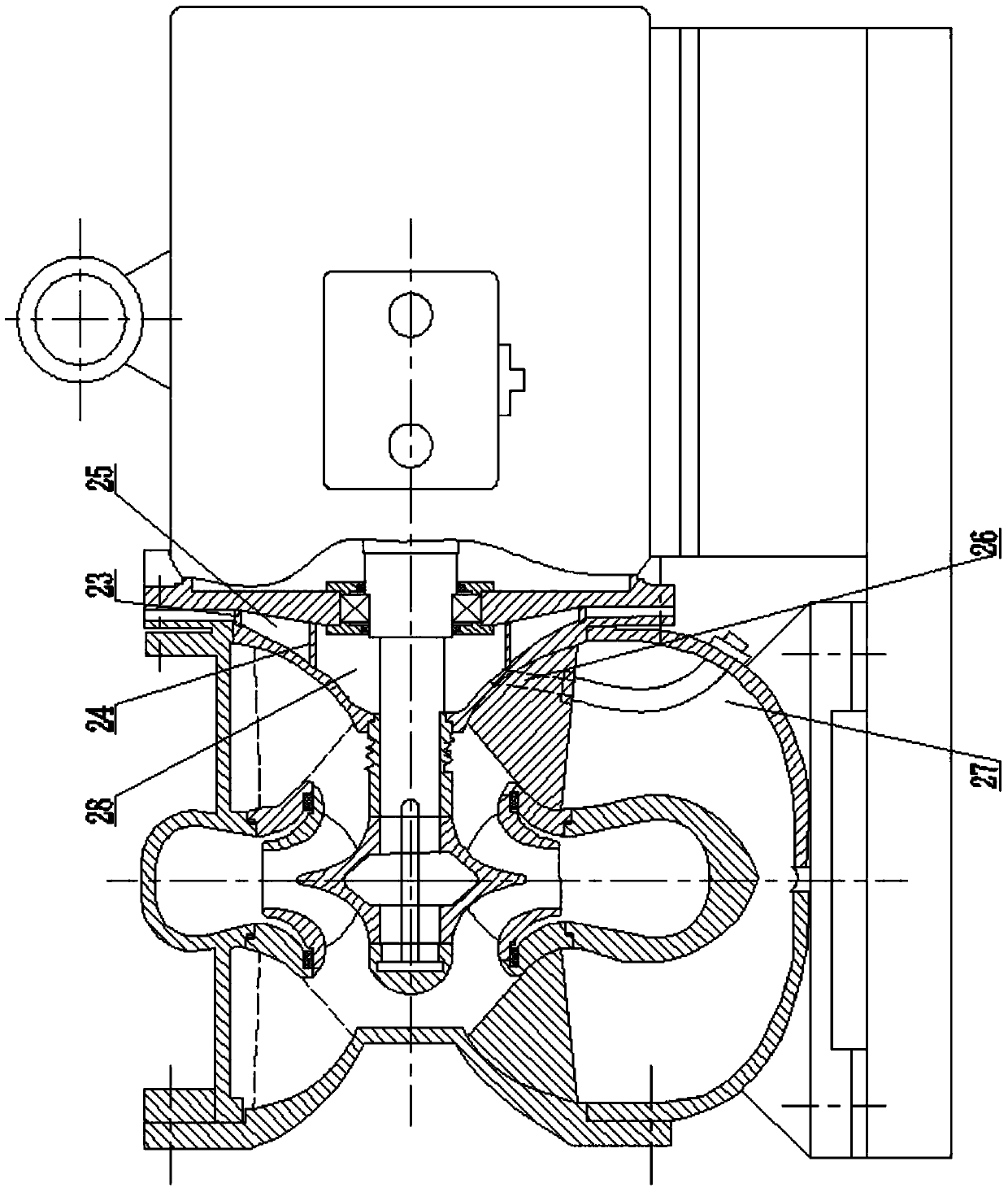

[0033] Such as figure 2As shown, in the energy-saving horizontal direct-connected single-stage double-suction centrifugal pump, the side cover 13 of the motor is connected and fixed to the pump cover II 12 on the corresponding side, and a cooling water isolation cavity 25 is arranged between the two. The side cover of the motor 13 is provided with concentric inner and outer annular male ports 24 and 23, and the pump cover II12 is provided with inner and outer annular female ports corresponding to the inner and outer annular male ports 24 and 23 respectively. The water isolation cavity 25 is surrounded by the side cover 13 of the motor, the pump cover II 12, and the inner and outer annular male seals 24, 23. The outer annular male seal 23 is respectively provided with an inlet and an outlet (omitted in the figure). In order to connect with the external cooling water system. The inner space 28 of the inner annular male stop 24 is provided with a discharge channel leading to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com