Emergency disposal method for accident of aluminum ethyl production system

A production system, triethylaluminum technology, applied in data processing applications, fire alarms, instruments, etc., can solve the problems of reactor overheating danger, complex production process, reactor explosion hazard, etc., to reduce personnel Casualties and property damage, fast emergency response, and reduced risk of injury

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The following examples are implemented according to the above-mentioned method of operation:

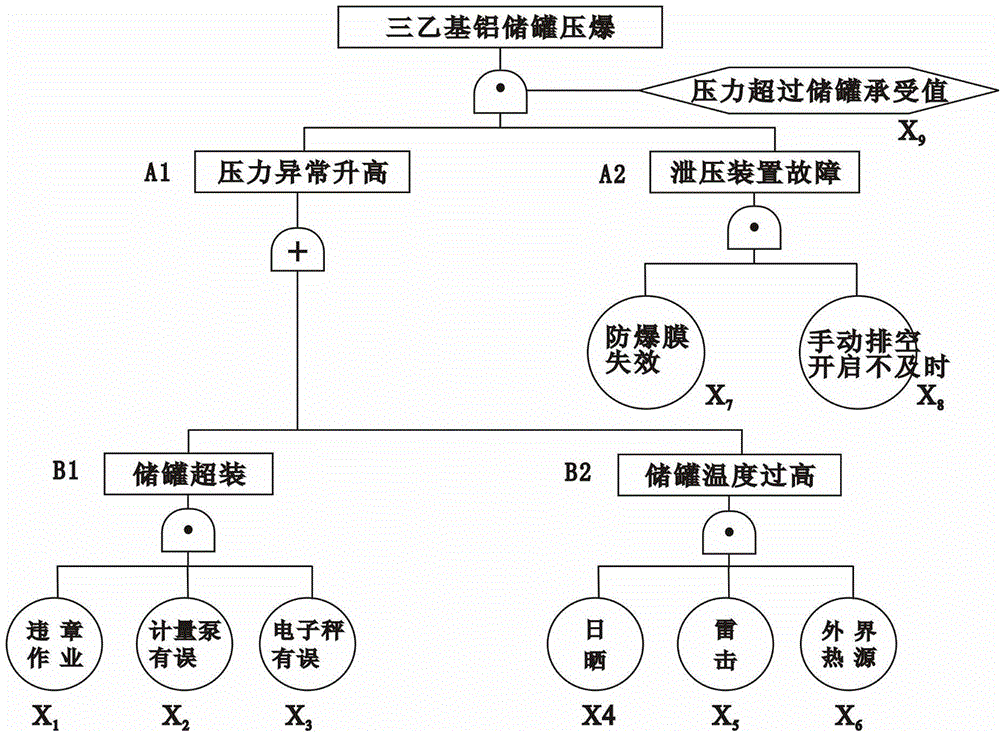

[0059] The triethylaluminum production system is mainly divided into multiple production units according to the production equipment, mainly including hydrogenation reaction production unit, ethylation reaction production unit, triethylaluminum storage tank unit, and filling unit.

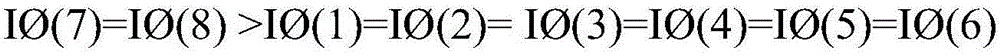

[0060] For each production unit's risk assignment, the degree of danger that the production unit may have in an accident is determined by the level of the risk score, and the accident level of the production unit is determined according to the risk score. The higher the risk score, the higher the accident level, and the greater the damage that the accident may cause.

[0061] The risk score of the production unit is the material fire risk score of the production unit, the risk score of the material capacity, the risk score of the temperature in the production process, the risk score of the pressure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com