USB3.1 (universal serial bus) connector socket with full-automatic manufacturing process and assembly manufacturing method for USB3.1 connector socket

A connector socket, a fully automated technology, applied to the parts of the connection device, the assembly/disassembly of the contact, and the connection, etc., can solve the problems of reduced processing yield, increased processing costs, and difficult control of processing quality. Improve production efficiency, simple structure, and easy control of processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

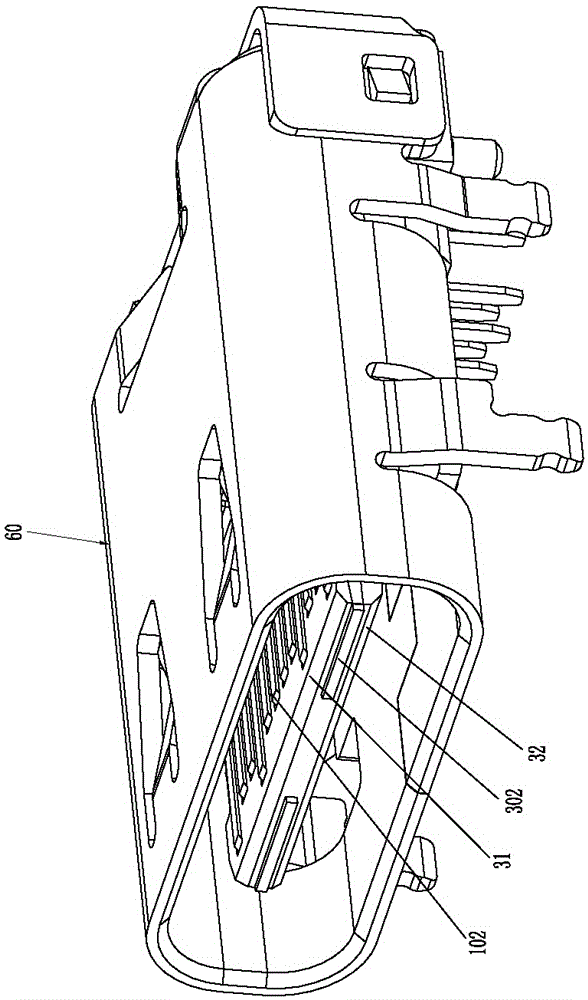

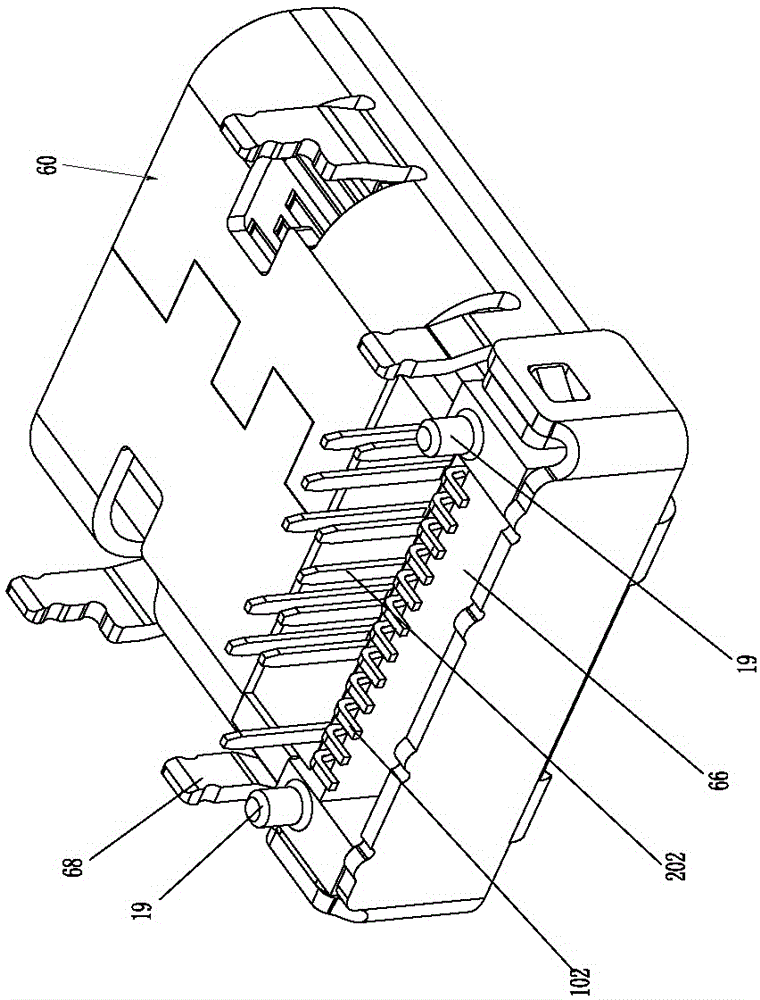

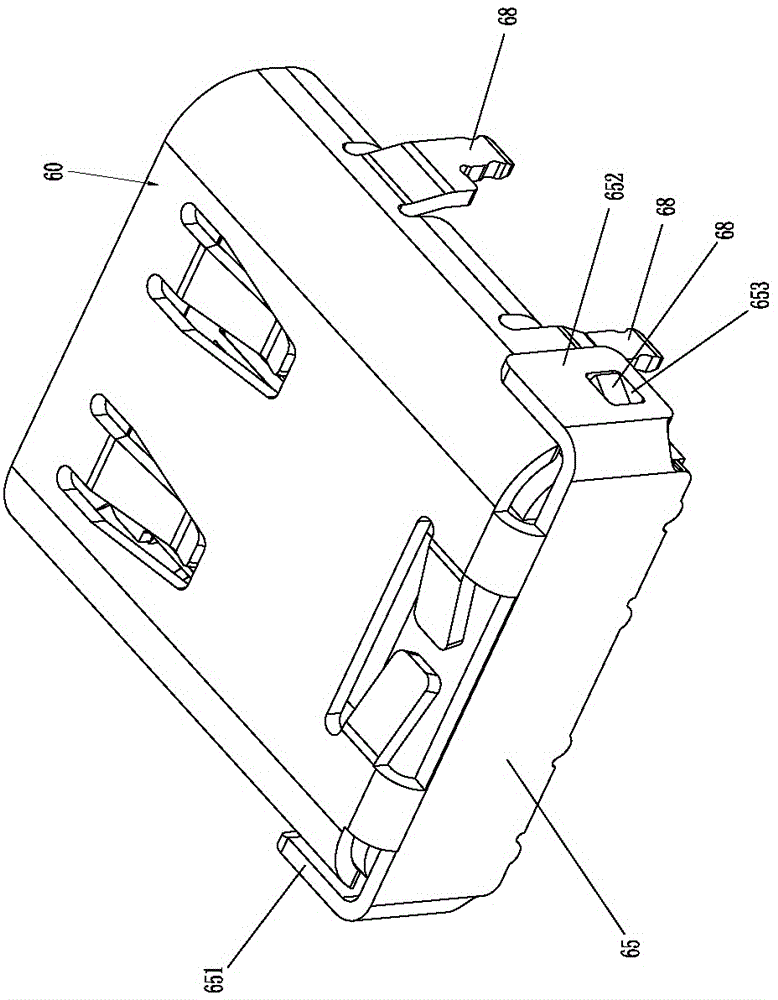

[0101] Please refer to Figure 1 to Figure 20 As shown, it shows the specific structure of the preferred embodiment of the present invention (here two embodiments are taken as examples for illustration), wherein, Figure 1 to Figure 17 The structure of the first embodiment is shown, which includes an SMT terminal module 10 , a DIP terminal module 20 , a partition module 30 , an upper EMI sheet 40 , a lower EMI sheet 50 and a shielding shell 60 .

[0102]Wherein, the SMT terminal module 10 includes a first terminal port 101 and a plurality of SMT terminals 102 embedded in the first terminal port 101, and the left and right ends of the first terminal port 101 are provided with upper EMI sheets 40 respectively. Embedded upper embedding groove 15; the front section of the SMT terminal 102 has a contact portion 11, and the rear section of the SMT terminal 102 is formed with an SMT soldering foot 12, and the contact portion 11 protrudes from the front end of the first terminal port ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com