Hydrogenation automation end execution mechanism

An end-execution, electric technology, applied in the direction of mechanical equipment, container filling methods, container discharge methods, etc., can solve the problems of dangerous working environment, high labor intensity of hydrogen refueling stations, and harsh environment, so as to reduce labor intensity and solve labor problems. Harsh hydrogenation environment, improved safety and hydrogenation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

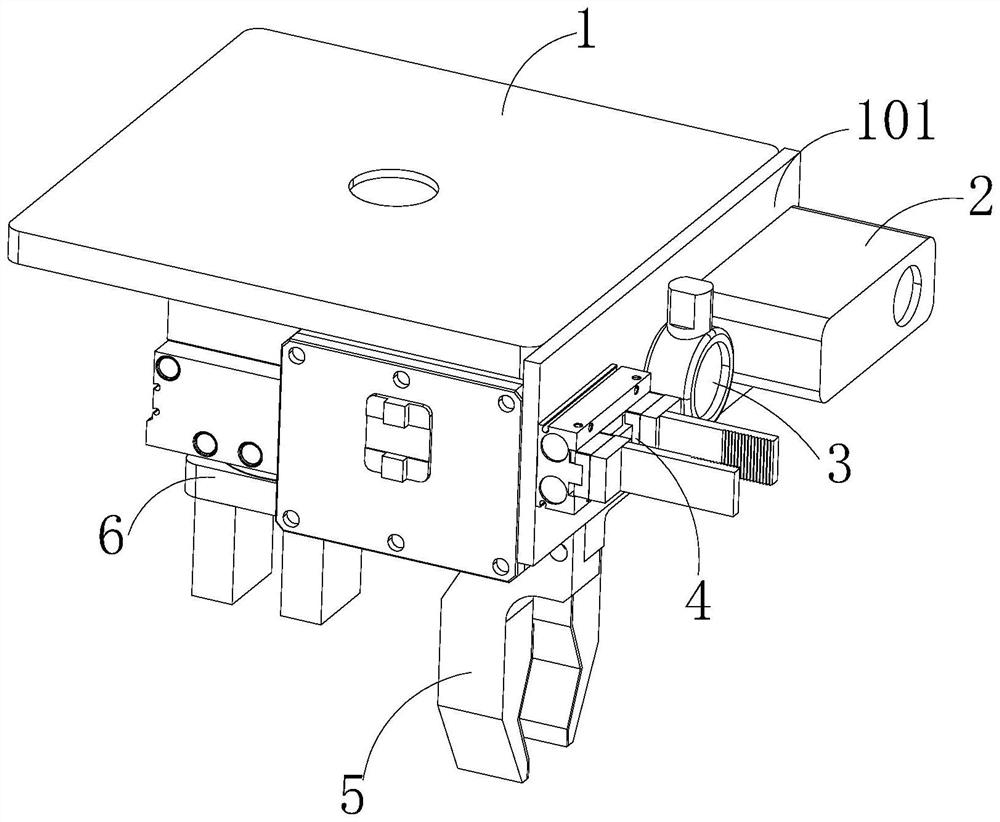

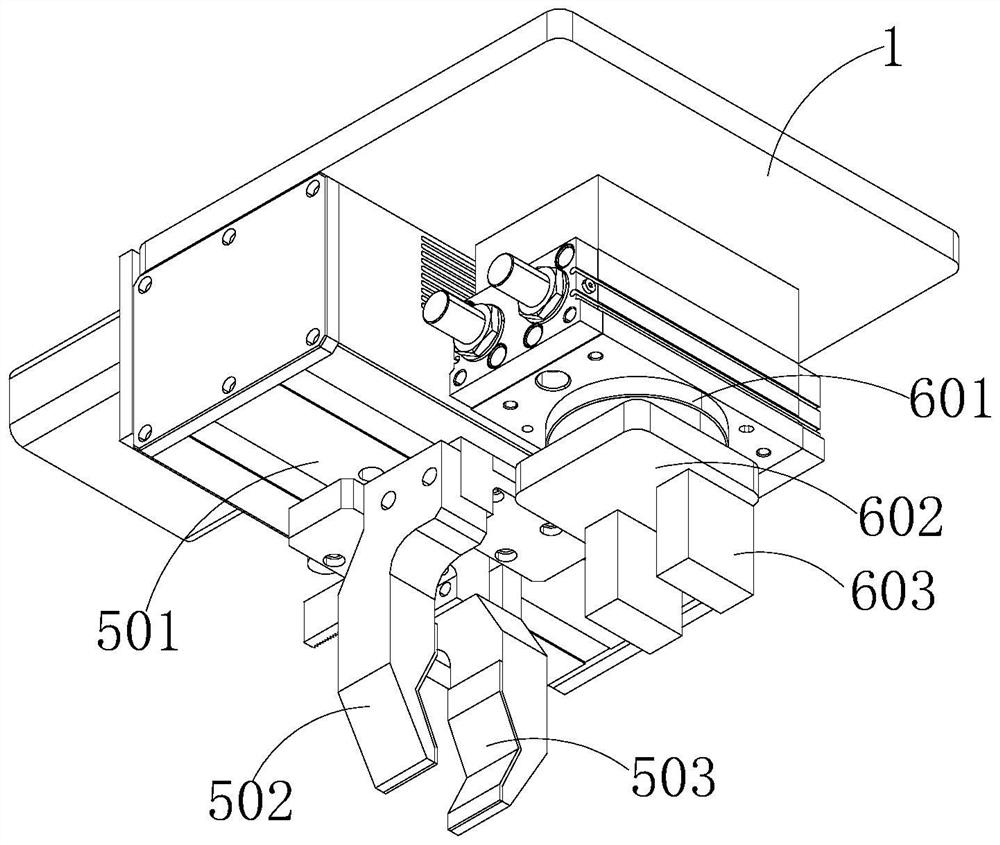

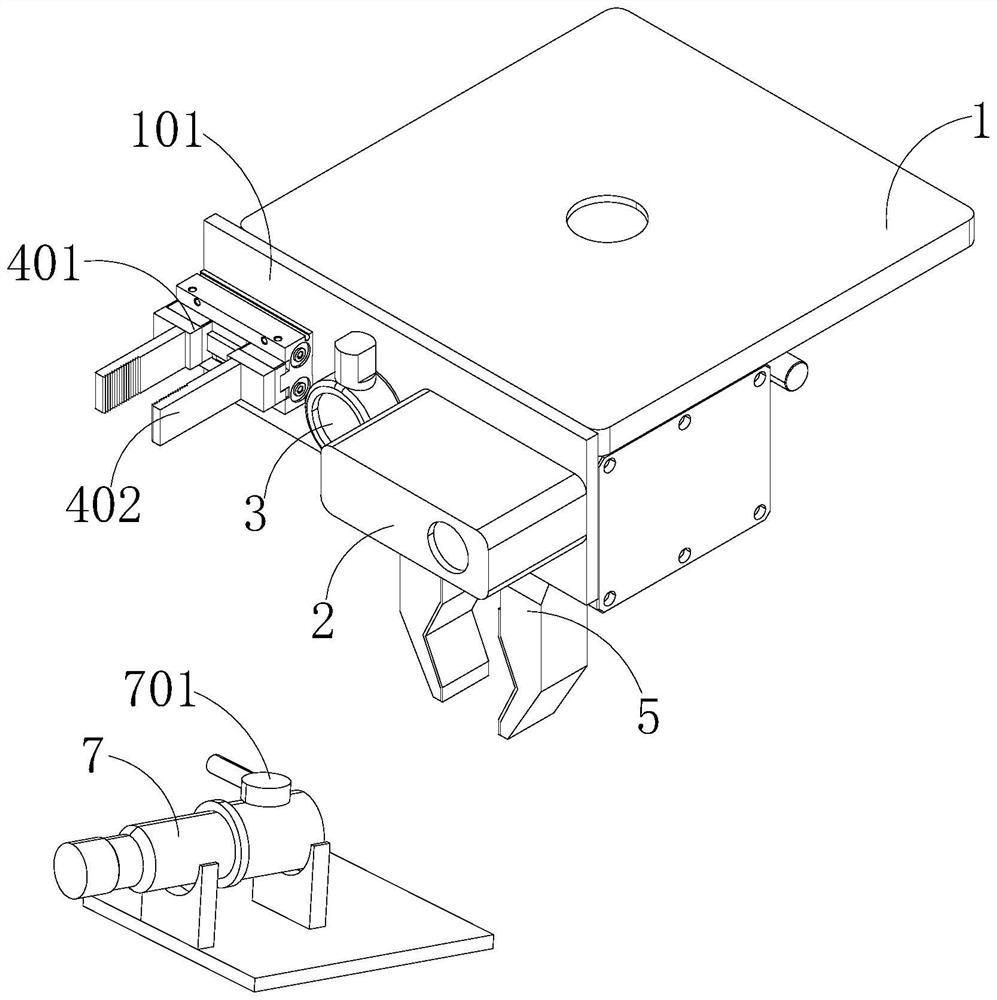

[0025] In order to make the objectives, technical solutions and advantages of the present invention clearer, the embodiments of the present invention will be further described below with reference to the accompanying drawings. What is described below is a preferred one among multiple possible embodiments of the present invention, and is intended to provide a basic understanding of the present invention, but is not intended to identify key or decisive elements of the present invention or limit the scope of protection to be protected.

[0026] In the description of the present invention, it should be noted that, unless otherwise expressly specified and limited, the terms "installation" and "connection" should be understood in a broad sense, for example, it may be a fixed connection, a detachable connection, or an integral connection. It can be a mechanical connection or an electrical connection; it can be a direct connection or an indirect connection through an intermediate mediu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com