Circuit board tin spraying process

A circuit board and process technology, which is applied in the field of circuit board tin spraying process, can solve the problems of affecting appearance, abnormal product quality, oil leakage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

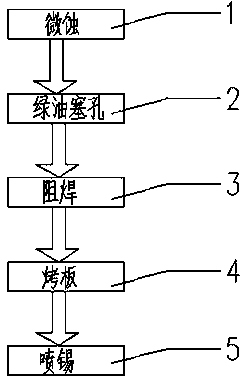

[0008] Such as figure 1 As shown, a circuit board tin spraying process, which includes micro-etching 1, green oil plug hole 2, solder mask 3, baking plate 4 and tin spraying 5 steps, the micro-etching 1 acts on the hole wall and the board surface. Form a microscopically rough surface; the green oil plug hole 2 is a double-sided plug hole, which effectively avoids the appearance of tin beads; the solder mask 3 forms a layer of ink protective layer on the surface of the circuit board; the baking plate 4 uses a temperature The step-by-step baking method of gradually increasing the temperature from 60°C to 150°C, the ink in the hole of the circuit board is not directly subjected to high temperature, but is gradually increased from low temperature to high temperature, so that the water-based solvent of the ink in the hole is completely volatilized, and the ink Slowly solidify in the hole, and the cured ink will not overflow on the edge of the hole; the time interval between the HAS...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com