System and method for use in automation engineering

An automation technology, mobile terminal technology, applied in general control system, technical management, control/adjustment system, etc., to prevent installation errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

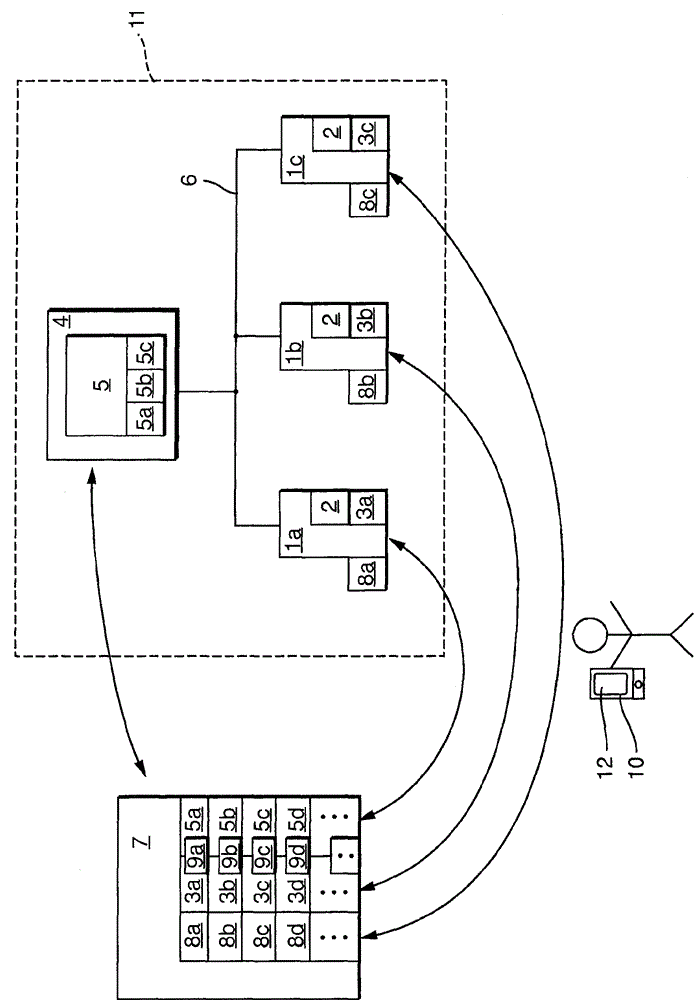

[0037] figure 1 Three field devices 1a, 1b, 1c equipped with basic firmware are shown configured for a specific application by application-specific firmware 3a, 3b, 3c. For example, a first field device 1a is configured for level measurement, a second field device 1b is configured for pressure measurement and a third field device 1c is configured for flow measurement. In this case, the field devices 1a, 1b, 1c have a basic firmware 2 via which the basic functions of the respective field device 1a, 1b, 1c are realized. This basic functionality is then established and each field device 1a, 1b, 1c is configured for the respective application by means of application-specific firmware 3a, 3b, 3c. Thus, for example, a first application firmware 3a is used for level measurement, a second application firmware 3b is used for pressure measurement and a third application firmware 3c is used for flow measurement. The field devices 1a, 1b, 1c are connected via a bus 6 to a superordinated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com