Multi-flavor and multi-nutrient puffed food and preparation method thereof

A puffed food, multi-nutrition technology, applied in the field of food processing, can solve the problems of only seeking crispness, high fat content, monotonous nutrients, etc., and achieves the effects of good color and fragrance, low fat content, and strong appetite.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-18

[0034] Table 1 is the semi-finished product formula of embodiment 1-6:

[0035] Table 1 The semi-finished product formula of embodiment 1-6, kg

[0036] Example

Example 1

Example 2

Example 3

Example 4

Example 5

Example 6

30

30

25

25

40

45

40

40

35

35

40

30

0.7

0.7

0.9

0.9

0.8

0.8

salt

0.1

0.1

0.2

0.2

0.3

0.3

glutinous rice flour

-

20

25

25

30

30

pumpkin pulp

7

10

8

6

-

-

sweet potato pulp

-

-

4

8

20

16

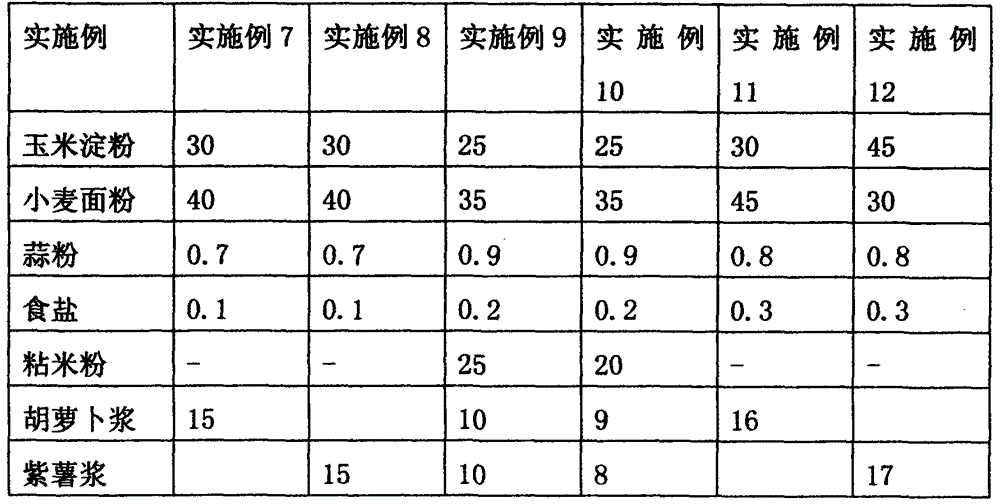

[0037] Table 2 is the semi-finished product formula of embodiment 7-12:

[0038] The semi-finished product formula of table 2 embodiment 7-12

[0039]

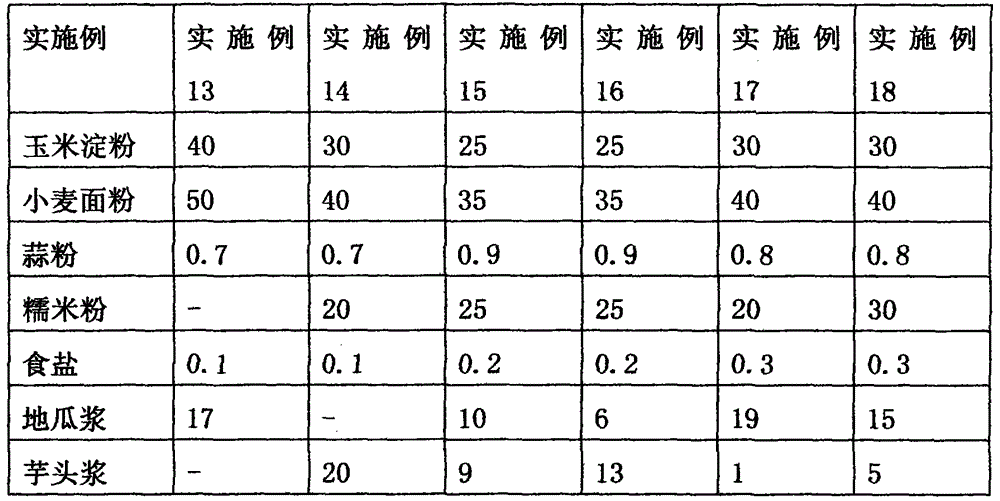

[0040] Table 3 is the semi-finished product formula of embodiment 13-18:

[0041] The semi-finished product formula of table 3 e...

Embodiment 19-24

[0072] The semi-finished product formula and boiled sugar formula of embodiment 19-24 correspond to the formula of embodiment 1-6 respectively, and the preparation method of embodiment 19-24 product is as follows:

[0073] (1) Process flow of semi-finished products:

[0074] Put the semi-finished formula raw materials into the blender and stir evenly, put them into the lower hopper of the extruder, adjust the heating in zone 1-5 to the set temperature, set the temperature in zone 1-5 to 90-180°C respectively, and wait When the temperature of each zone rises to the set temperature, the main engine speed system and the feeding system can be started, and the raw ingredients are extruded from the barrel and screw;

[0075] At this time, you should check whether the raw material is fully matured. After the raw material is fully matured, close the machine head with the mold installed, tighten the screw of the machine head, and start the pelletizing system of the machine head after t...

Embodiment 25-30

[0082] The semi-finished product formula of embodiment 25-30 corresponds to the formula of embodiment 7-12 respectively, and the preparation method of embodiment 25-30 product is as follows:

[0083] (1) Process flow of semi-finished products:

[0084] Put the semi-finished formula raw materials into the blender and stir evenly, put them into the lower hopper of the extruder, adjust the heating in zone 1-5 to the set temperature, set the temperature in zone 1-5 to 90-180°C respectively, and wait When the temperature of each zone rises to the set temperature, the main engine speed system and the feeding system can be started, and the raw ingredients are extruded from the barrel and screw;

[0085] At this time, you should check whether the raw material is fully matured. After the raw material is fully matured, close the machine head with the mold installed, tighten the screw of the machine head, and start the pelletizing system of the machine head after the clinker is extruded ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com