Apparatus and method for processing micropore through filamentous laser

A technology of laser filament formation and micro-holes, which is applied in laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of easy collapse of micro-holes, limited diameter of micro-hole drilling, etc., to solve the problem that the taper is difficult to control. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further elaborated below with reference to the accompanying drawings.

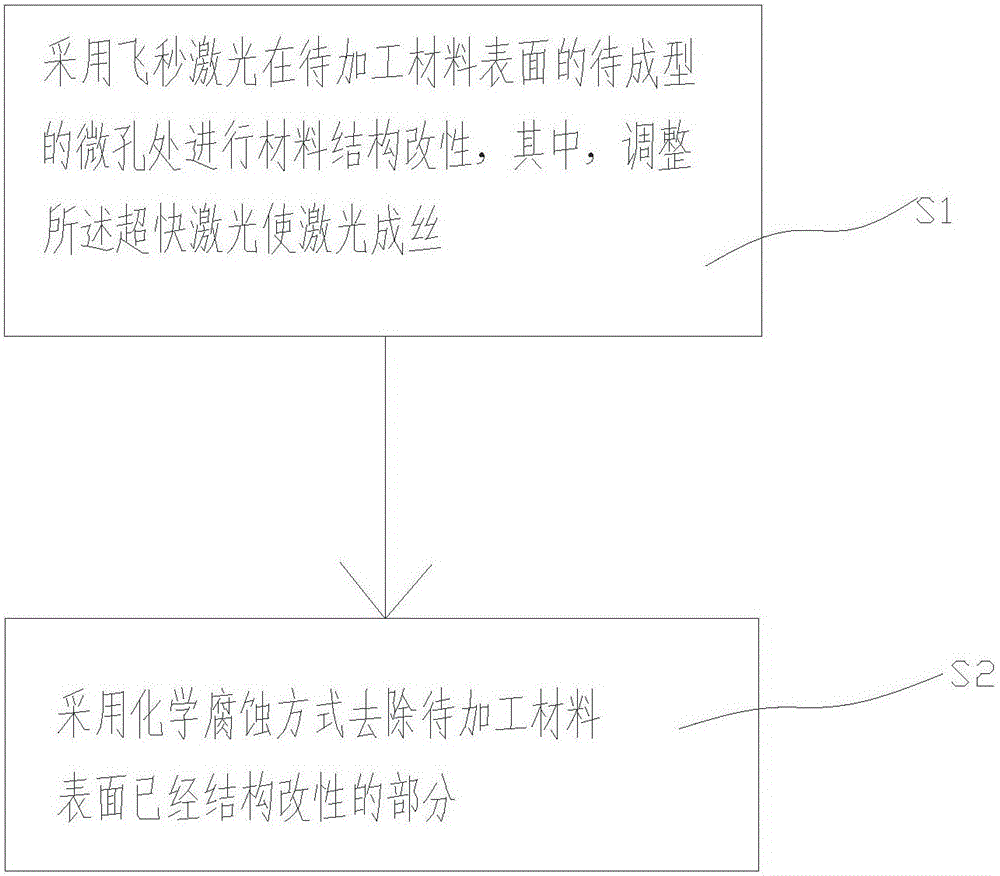

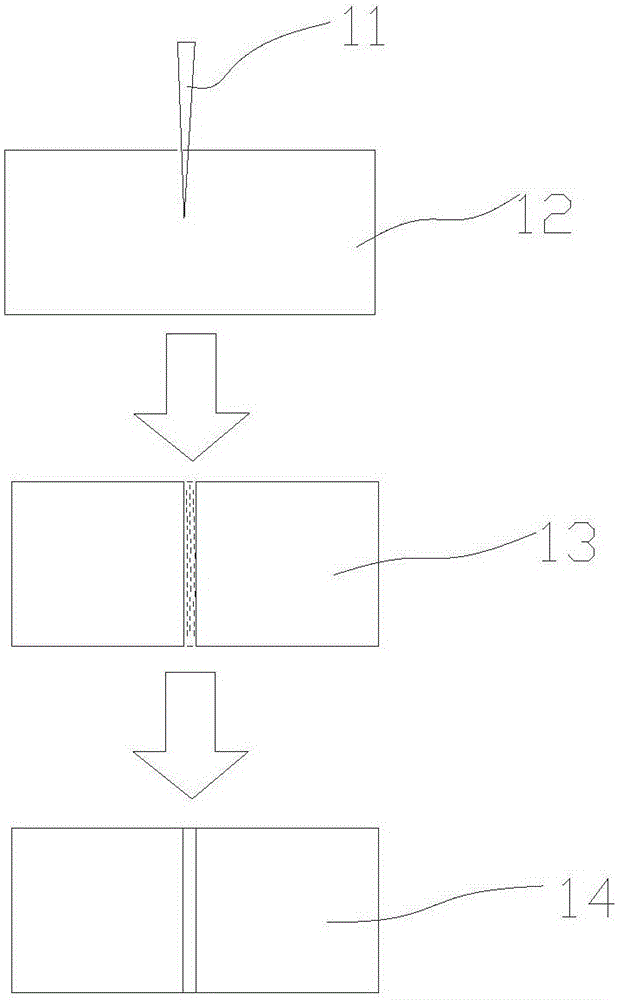

[0025] Ultrafast laser filamentation: Laser filamentation means that when ultrafast laser pulses are transmitted in the air medium, due to the combined action of the self-focusing effect and the defocusing phenomenon caused by the plasma generated after ionizing the air, a dynamic balance is achieved, so that Ultrafast laser pulses form long, relatively stable laser channels in air. The mechanism of laser filamentation on transparent materials, such as sapphire, glass, etc., is approximately the same as that in air. Therefore, it can be directly used in the micropore processing technology of transparent materials. Wherein, the above-mentioned ultrafast laser is picosecond or femtosecond laser.

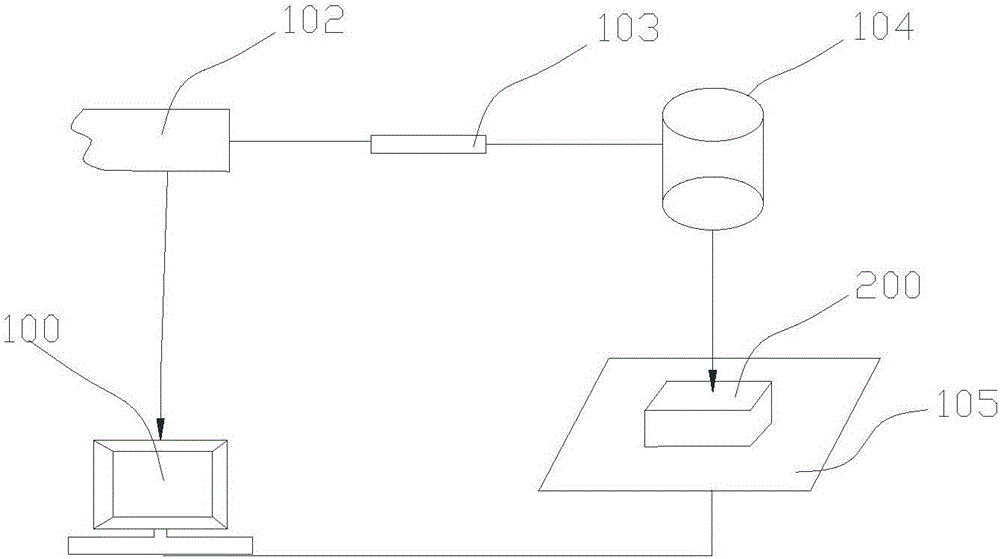

[0026] see figure 1 , in this embodiment, the device of the present invention for processing microholes by laser wire forming is used for processing microholes with a diamete...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com