Machining method for large-sized inner-hexagon blind hole

A processing method and large-size technology, which is applied in the processing field of large-size internal hexagonal blind holes, can solve the problems of high labor intensity and low efficiency, and achieve the effects of low labor intensity, improved efficiency, and stable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

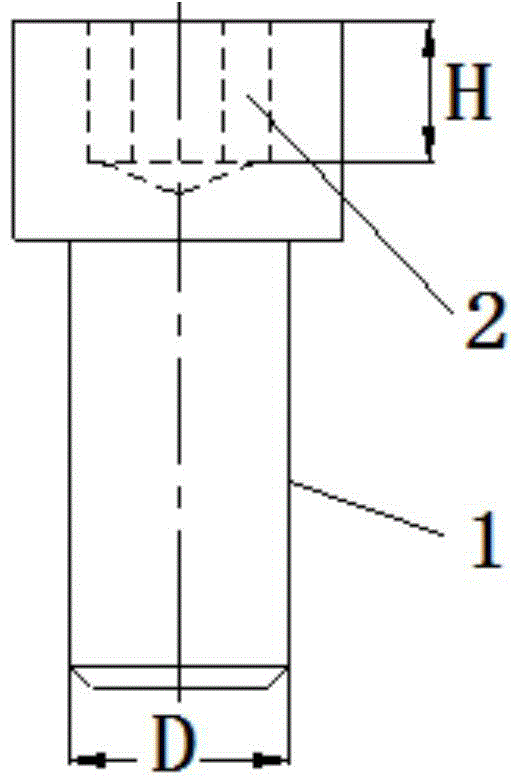

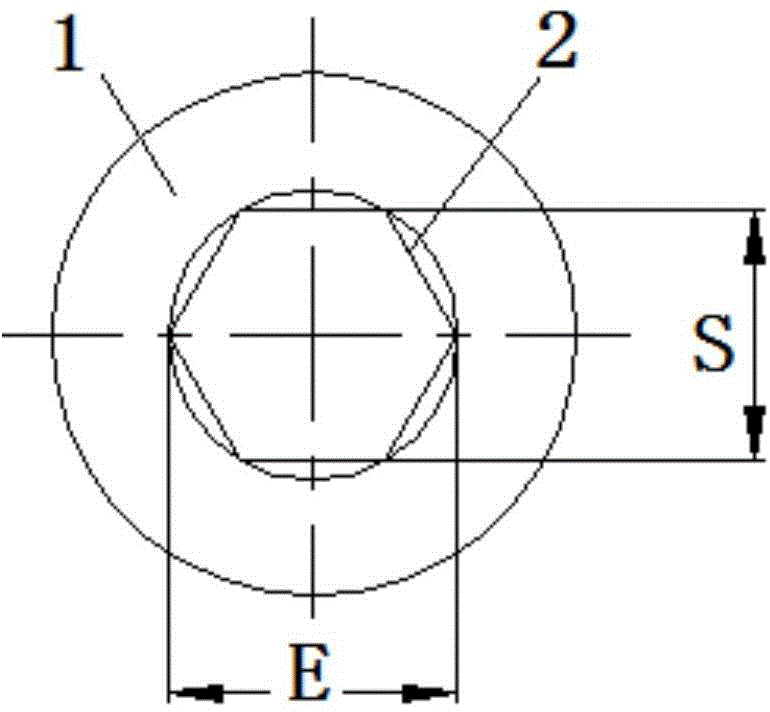

[0027] refer to figure 1 and figure 2 , is the structure of the large-size inner hexagonal blind hole workpiece 1 to be processed in the present invention. An inner hexagonal blind hole 2 is designed at the center of the large end face of the workpiece 1. The diameter of the outer circle of the small end of the workpiece 1 is D, and the inner hexagonal blind hole 2 The diameter of the circumscribed circle is E, the relative plane distance of the inner hexagonal blind hole 2 is S, and the blind hole depth of the inner hexagonal blind hole 2 is H.

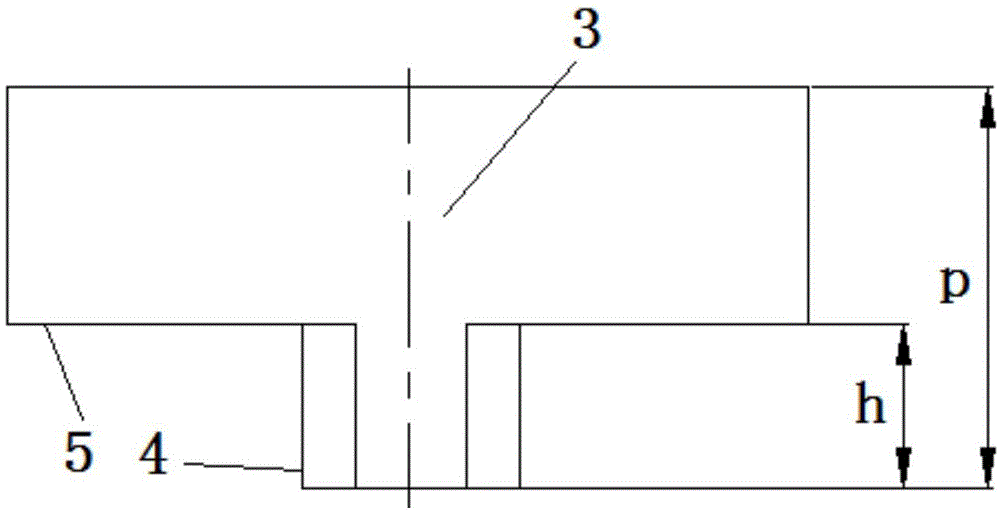

[0028] The processing tooling that the inventive method adopts comprises inner hexagonal punch 3, horizontally arranged opening backing plate 6 and vertically arranged opening pressing plate 8, two equal-height pads one 10 and two equal-height pads two 12,

[0029] refer to image 3 and Figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com