A horizontal garbage bag breaking machine

A bag breaking machine and garbage technology, which is applied in the field of garbage plastic bags, can solve the problems that plastic fragments cannot be separated, it is difficult to handle plastic bags, and the effect of crushing is affected, so as to reduce the number of shutdowns to clean plastic winding knives, and has wide application prospects and practicality. Excellent value, convenient and quick installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

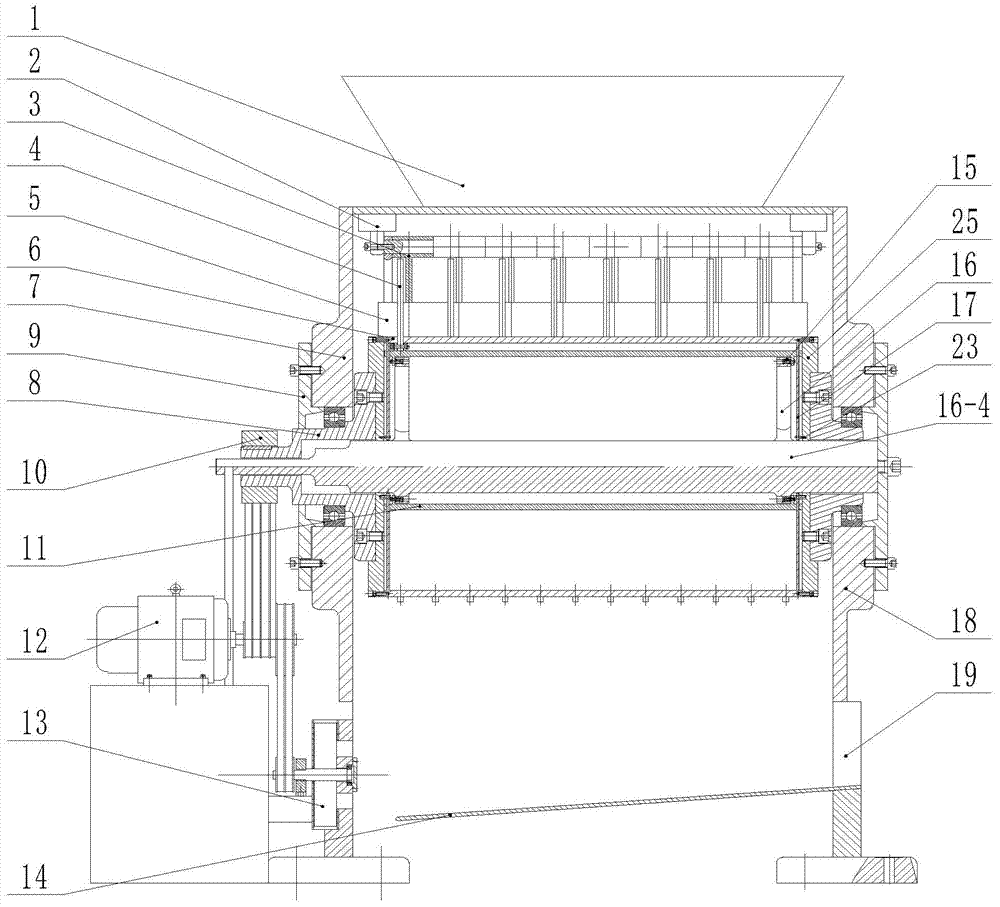

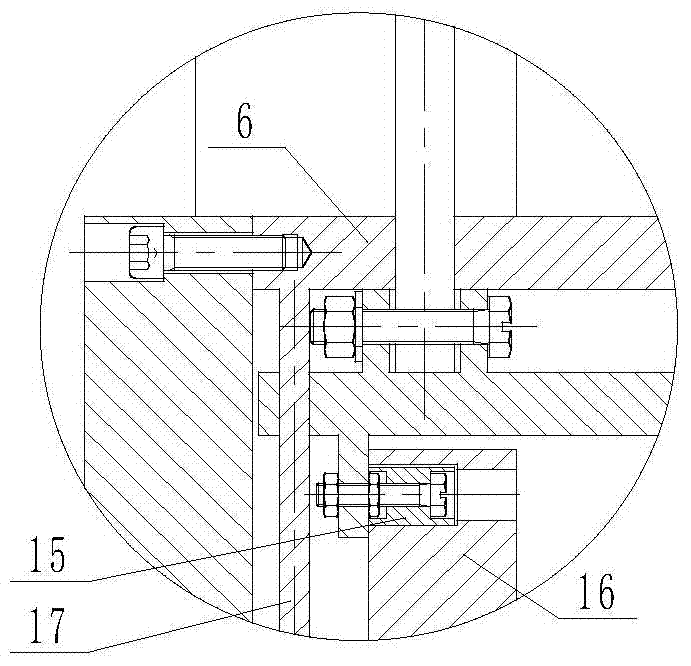

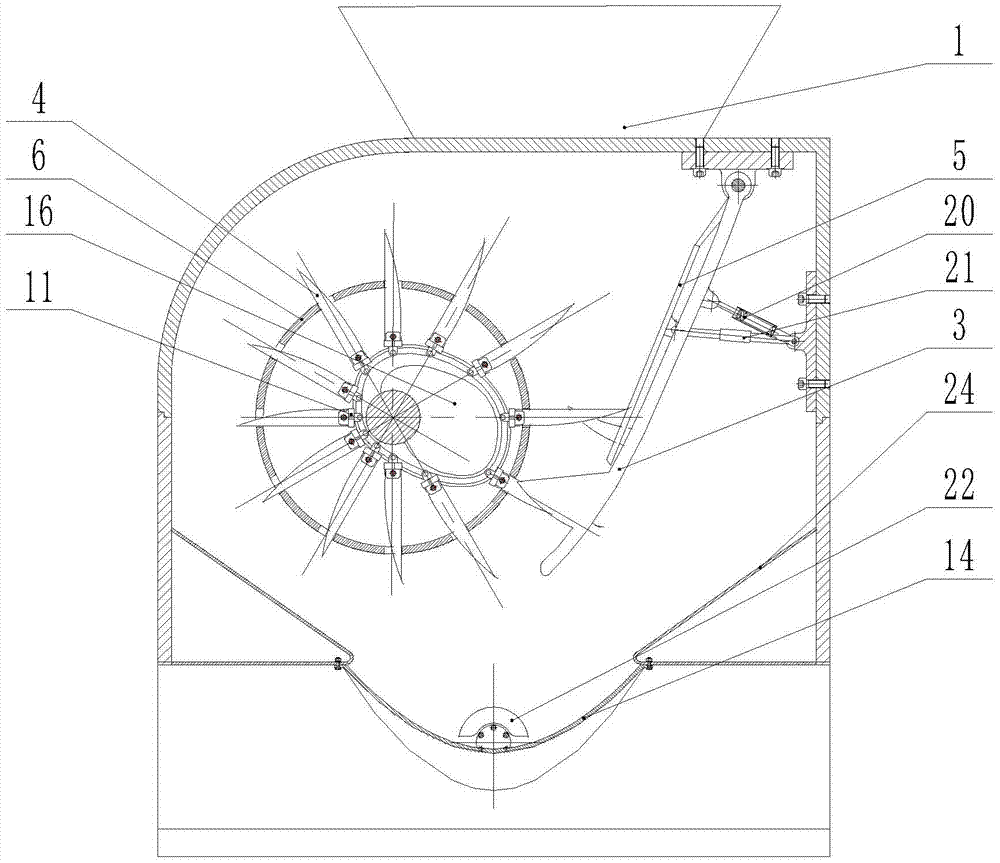

[0049] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0050] Such as figure 1 , figure 2 As shown, the horizontal garbage bag breaker of the present invention includes a closed box body with a discharge port 1 on the top, a fixed cam mechanism 16, a drum 6 and a fan 13 driven by a motor 12 to rotate on the box body , The cylinder 6 is provided with a moving knife mechanism, and the casing is also provided with a fixed knife mechanism intersecting with the moving knife mechanism, correspondingly, the bottom thereof is provided with a V-shaped groove 24, and the bottom of the V-shaped groove 24 is provided with a U-shaped discharge groove 14. The fan 13 is driven by the belt pulley fixed on the sliding bearing driven by the motor 12. The bracket corresponding to the fan 13 is provided with a discharge port 19. Below the discharge port 19 is a U-shaped discharge groove 14, and the fan port 22 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com