Method and device for producing aramid fiber yarn and its aramid core-spun yarn by mechanical compact spinning, and the prepared aramid core-spun yarn

A technology of aramid fiber and compact spinning, which is applied in the field of aramid core-spun yarn, which can solve the problems of easy exposure of the core material of the core-spun yarn and excessive hairiness, and achieve the effects of low environmental requirements, small differences between spindles, and precise structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

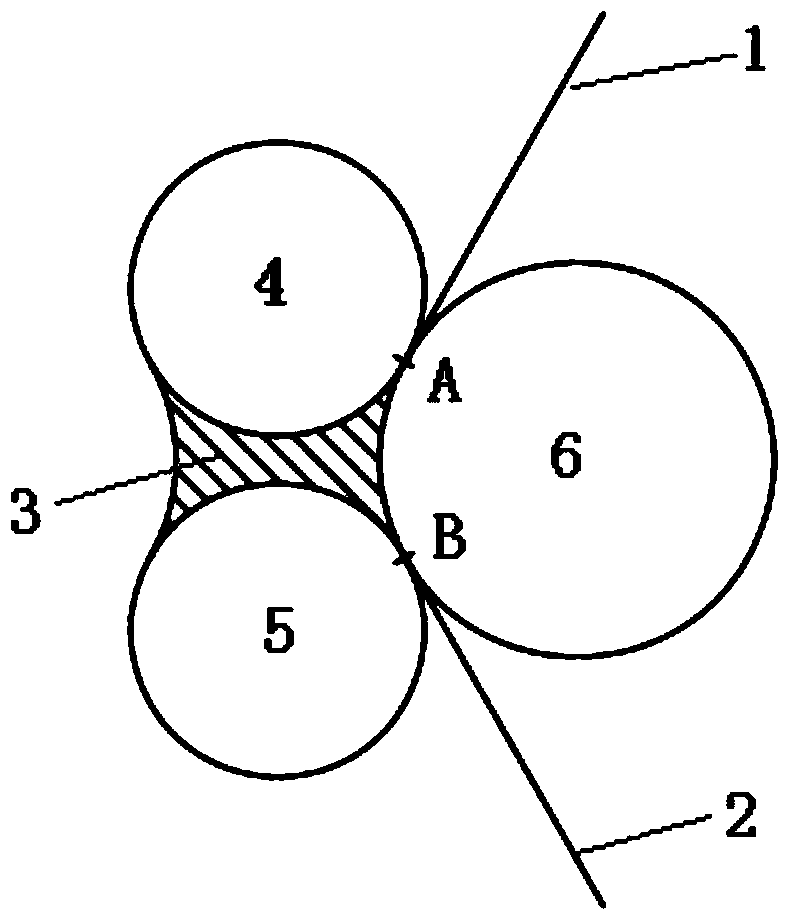

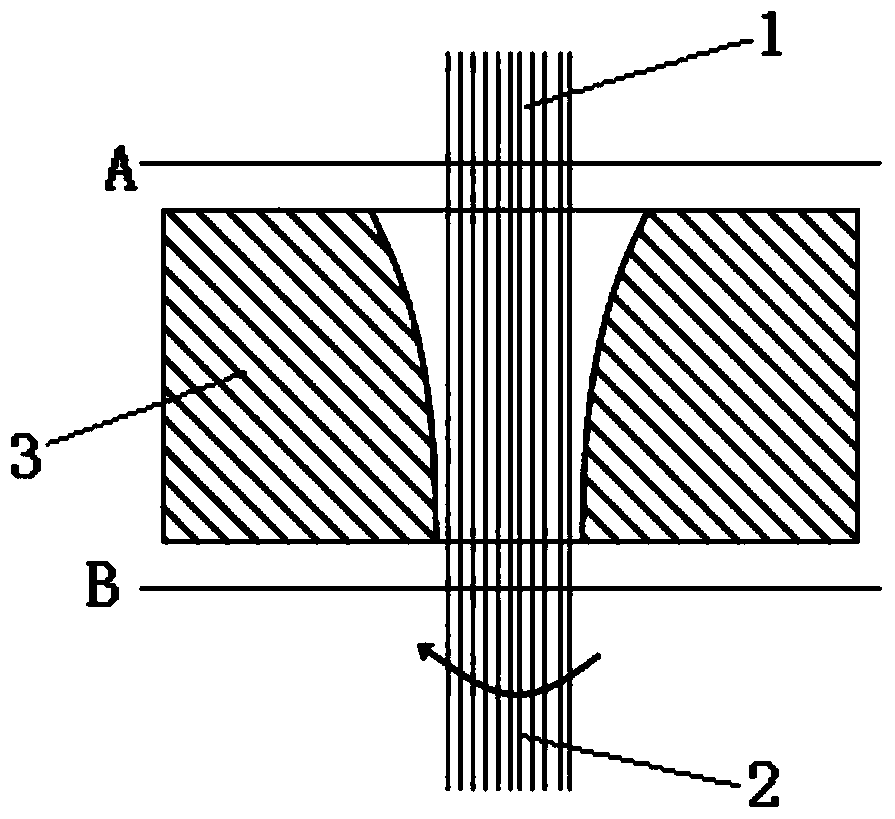

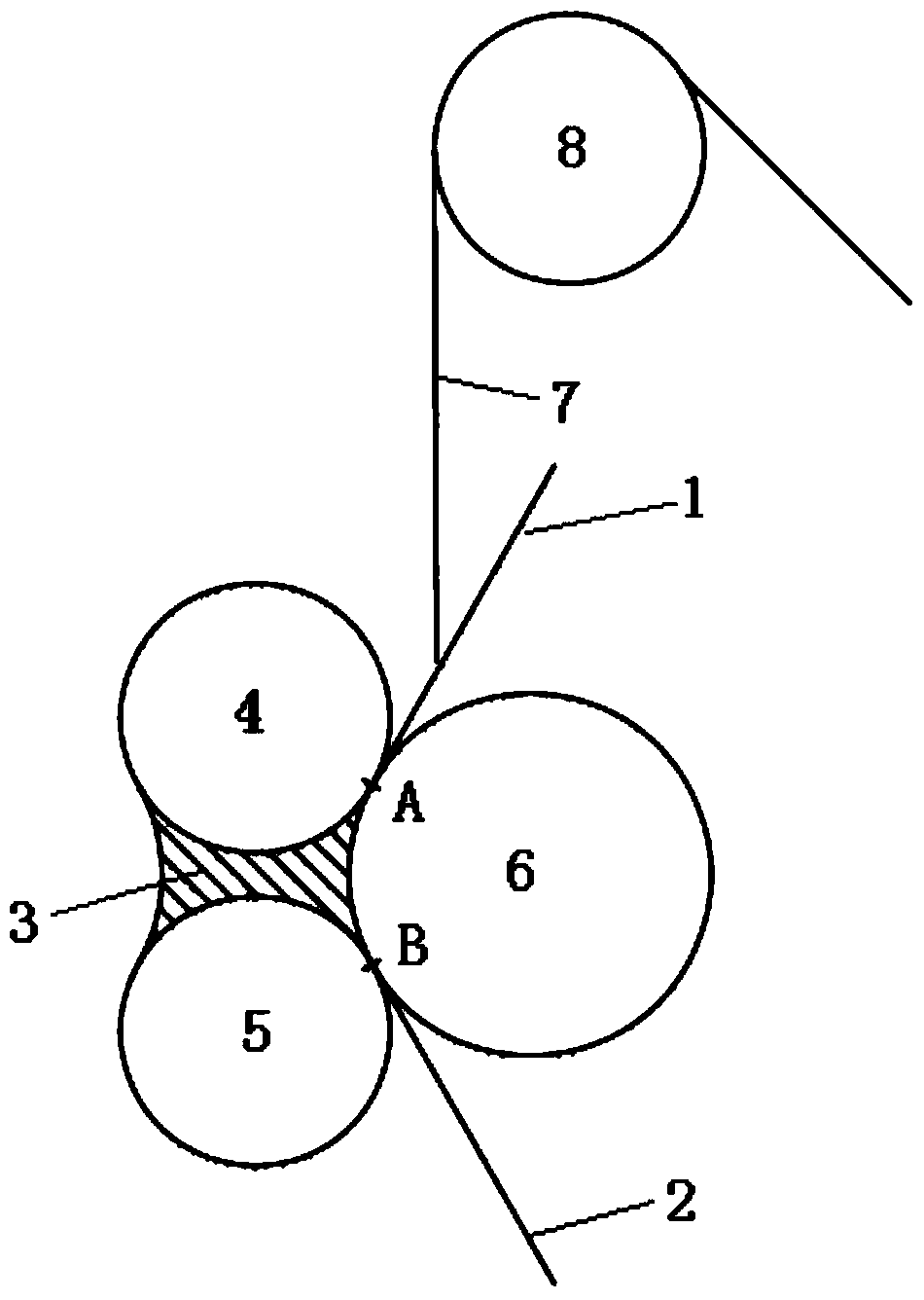

Method used

Image

Examples

Embodiment 1

[0042] In addition to removing the front top roller 4 of the spinning frame for spinning aramid in the above example 1, it was replaced with a mechanical compact spinning device 3 and then the front top roller 4 was installed. Other technical parameters remain unchanged. Using a roving sliver with a basis weight of 5.1g / 10m, 30Ne is spun to obtain a single yarn twist of 871TPM. The performance of the yarn is measured as shown in Table 1.

Embodiment 2

[0046] The spare roving sliver with a basis weight of 5.1g / 10m is used on a spinning frame equipped with a core-spun device and grafted with a compact spinning device. The stainless steel fiber with a diameter of 0.05mmr is selected as the core material to facilitate the transmission and control of the precision guide wheel. Accurately align the center of the roving sliver and converge with the yarn feeding jaw A to spin 12Ne para-aramid core-spun yarn with a yarn twist of 499 TPM. The tested yarn properties are shown in Table 2.

[0047] Table 1 Comparison of yarn properties between Comparative Example 1 and Example 1

[0048]

[0049] Table 2 Comparison of yarn properties between Comparative Example 2 and Example 2

[0050]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com